Anchor Bolt Pull Out Tester

Anchor Bolt Pull Out Tester Specification

- Application

- Testing the anchoring force of various anchors, rebars, expansion bolts, and other anchoring components

- Material

- Thicker high strength steel

- Usage

- Anchor Bolt Pull Out Tester

- Dimension (L*W*H)

- 480200405mm Millimeter (mm)

Anchor Bolt Pull Out Tester Trade Information

- Minimum Order Quantity

- 1 Number

- Sample Available

- Yes

- Main Domestic Market

- All India

About Anchor Bolt Pull Out Tester

Pull-out testing involves attaching a suitable test rig to the bolt, screw, anchor or fixing. This is then put under tension to the designed stress load level to determine how strong and secure the fixing is.

This type of service enables potential early diagnosis of underlying problems and our engineers can offer honest and impartial technical advice in the event of a failure should this occur.

Application Field

Isa portable anchor bolt pull-out tester that can be used to test the anchoringforce of anchoringrods, steel rods, expansion bolts, and another anchoring devices. It issuitable for all kinds of anchor bolts, reinforcement, expansionbolts, and other anchorage force tests, also do the glass curtain wall on-the-spot anti-pull force test (test), is the quality inspection unit necessary testinstrument

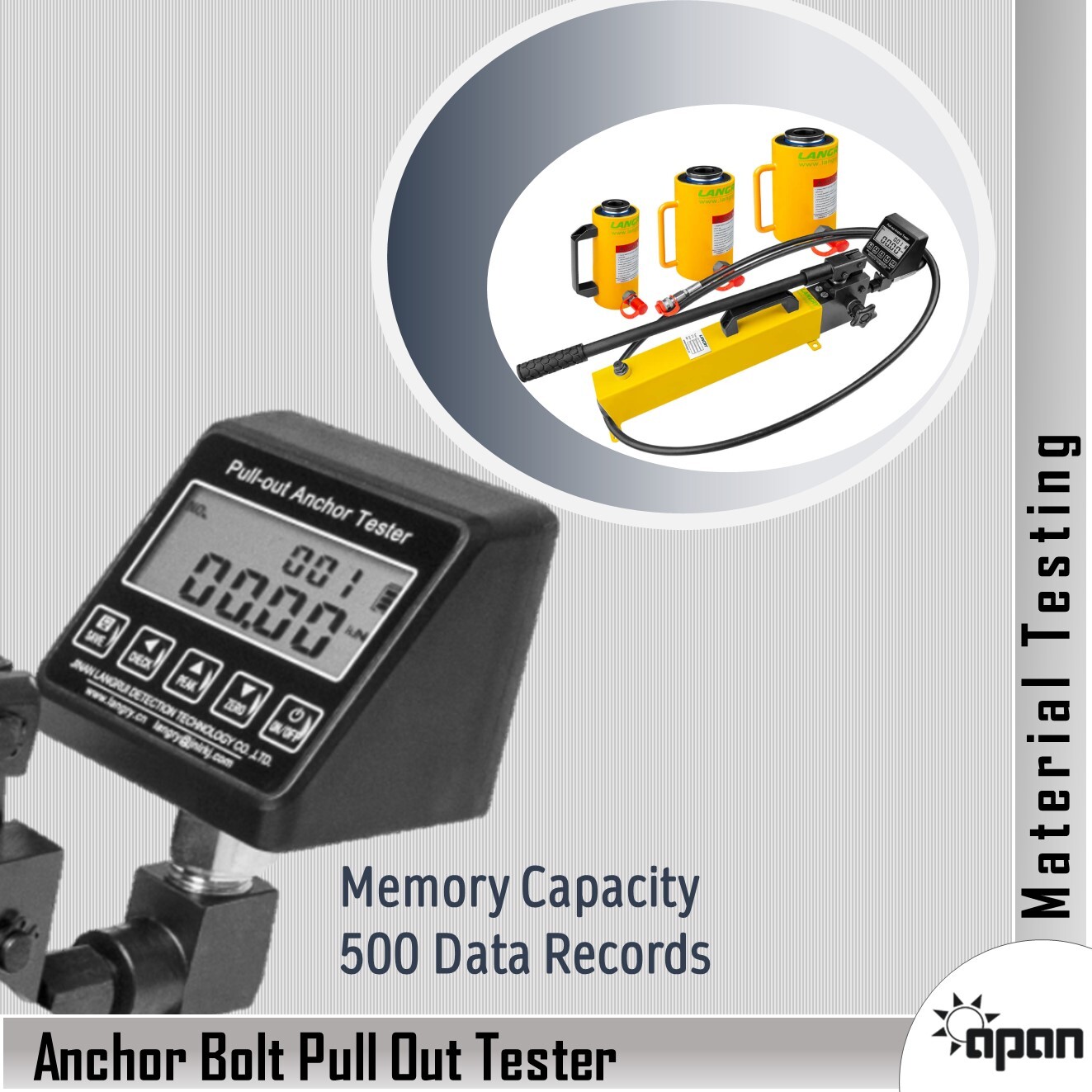

ForceNumerical Indicator

Theintegrated digital force numerical indicator adopts high-quality andhigh-impedance pressure sensors. It has good linearity, convenient calibration,stable force output, high precision, and no temperature drift with integrateddust-proof buttons.

Product Features

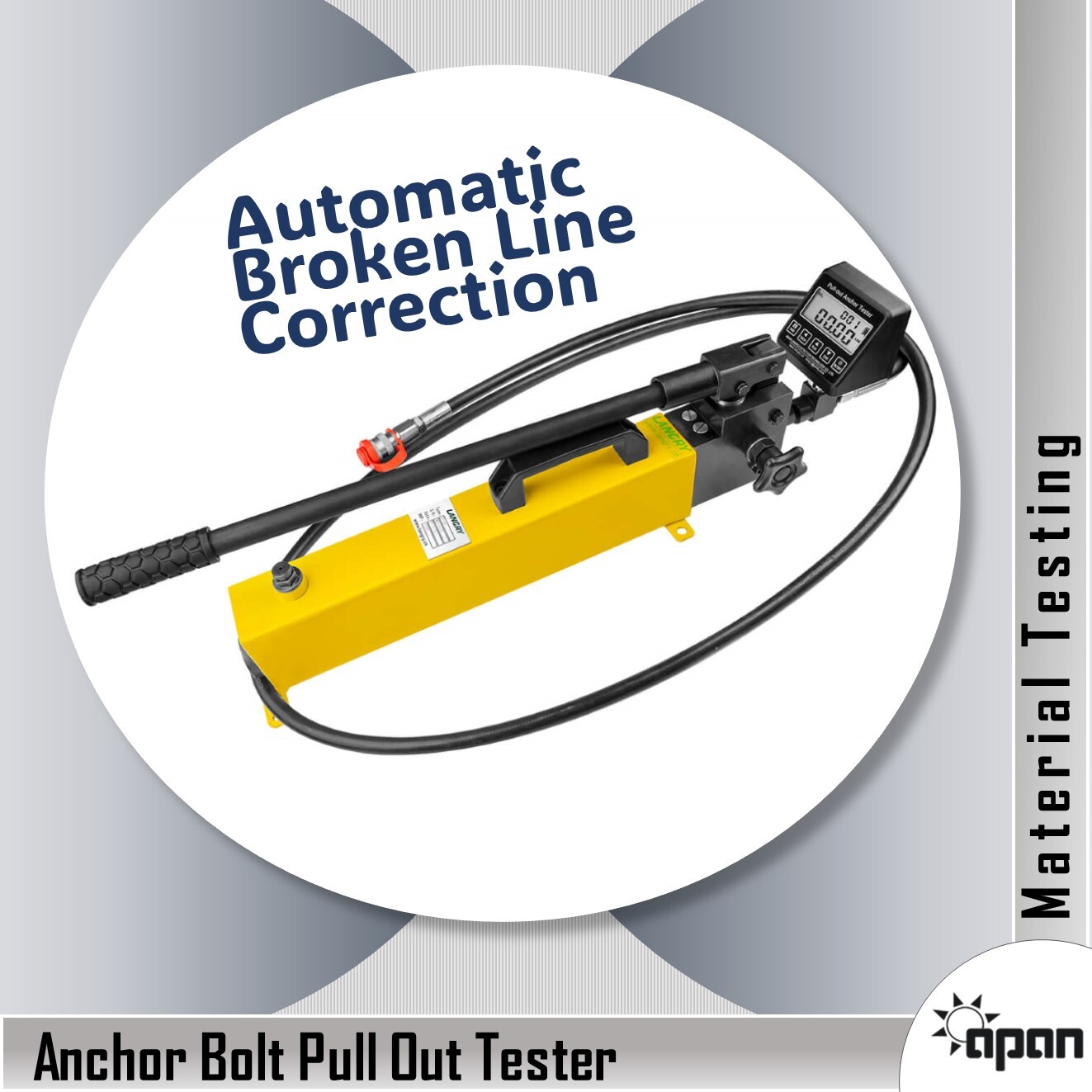

(1) High-strength steel thickening main body, high pressure does not deform

(2)Oilpump and one-way valve precision processing constant pressure when no oilseepage, pressure remains constant;

(3)Memory500 data records, lattice LCD lighting function;

(4)Zerotracking peak value and automatic shutdown;

(5)Numericalautomatic line correction to improve the accuracy of the instrument;

(6)LCDhas a wide field of vision, which is convenient for reading data.

(7)Ultra-lowpower design, continuous working time can exceed 200 hours.

Measurement range : 0-100 KN / 0-200 KN / 0-300 KN / 0-500 KN / 0-1000 KN

Anchor Range : 6-20 / 6-25 / 6-32 / 6-40 / 25-50

Robust High-Strength Steel Construction

Engineered from thicker high-strength steel, the tester guarantees resilience and enduring performance under rigorous usage. Its durable frame minimizes deformation, ensuring consistent and reliable testing results even with frequent use.

Versatile Application Across Anchoring Components

This tester efficiently evaluates the pull-out force of a wide array of anchoring elements, including anchors, rebars, and expansion bolts. Its an essential instrument for construction projects, maintenance, and quality control applications.

Compact Design for Convenient Operation

With dimensions of 480200405mm, the device is compact enough for easy handling and transport, yet robust enough for stable testing. The ergonomic layout makes it user-friendly for on-site or laboratory operations.

FAQs of Anchor Bolt Pull Out Tester:

Q: How is the Anchor Bolt Pull Out Tester used for evaluating anchoring components?

A: The tester is placed over the installed anchor, rebar, or expansion bolt. By applying controlled force, it measures the force required to pull the anchor out, providing precise readings for assessment of anchoring strength.Q: What types of anchoring components can be tested with this instrument?

A: It is suitable for testing various anchors, rebars, expansion bolts, and a broad range of other anchoring components, making it versatile for numerous construction and industrial tasks.Q: When should the Anchor Bolt Pull Out Tester be used?

A: The tester is best utilized during quality control inspections, safety assessments, or the installation phase to verify the secure holding capacity and reliability of anchoring devices.Q: Where can this tester be operated effectively?

A: Due to its manageable size, the tester is well-suited for both field and laboratory environments, enabling flexibility for diverse testing requirements on-site or in controlled conditions.Q: What is the testing process using this pull out tester?

A: After securing the tester to the anchor, controlled force is applied until the anchor is extracted or a specified load is achieved. This process quantifies the anchoring capacity of the component being tested.Q: What benefits does this tester offer to distributors and suppliers?

A: Distributors and suppliers gain a reliable and robust testing tool that ensures product compliance with industry standards, reduces the risk of anchor failure, and enhances credibility with clients and regulatory bodies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Portable Hardness Tester ASTM A956

Specimen Size : Minimum weight 0.1 kg (with support ring)

Features : Portable, digital, memory storage, auto poweroff, calibration

Measuring Range : 170960 HL (Leeb)

Application : Metallic material hardness measurement

Usage : Industrial/Field Hardness Testing

Accuracy : 4 HL (for D type impact device)

Digital Rockwell & Superficial Hardness Tester

Specimen Size : Max Height 230 mm, Depth 150 mm

Features : Digital Display, Automatic Loading/Unloading, Memory Function

Measuring Range : HRB, HRC, HR15N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W

Application : Metallurgy, Quality Control, Laboratory

Usage : Hardness Testing of Metals

Accuracy : 1 HR

Linear Abrasion Tester

Specimen Size : Maximum 100 mm 100 mm

Features : Adjustable test speed, programmable cycles, easy specimen mounting, easytoclean design

Measuring Range : 0999,999 cycles

Application : Assessment of abrasion resistance for coated, painted, and printed surfaces

Usage : Laboratory, quality control

Accuracy : 1 cycle

Digital RockwellHardness Tester

Specimen Size : 2 mm to 60 mm

Features : Direct digital reading, memory function, automatic/manual operation modes

Measuring Range : 20100 HRC

Application : Hardness testing of metals and alloys

Usage : Industrial laboratory, material analysis

Accuracy : 1 HRC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry