Concrete Moisture Meter

Concrete Moisture Meter Specification

- Temperature

- 0-50 Celsius (oC)

- Voltage

- 9 Volt (v)

- Dimension (L*W*H)

- 190 x 70 x 49 Millimeter (mm)

- Color

- Yellow black

- Weight

- 225 Grams (g)

- Control Mode

- Manual

About Concrete Moisture Meter

Types of Moisture Meters

On porous materials such as concrete, plaster, brick, wood, the moisture content of the substrate should be measured, as the presence of moisture within a material will result in poor adhesion, premature coating failure and poor appearance.

It is not sufficient to simply ensure that the surface is dry as often the surface of the substrate is the driest point due to evaporation. It is important to establish the moisture content within the substrate itself.

When powder coating wooden panels, for example, if the wood (or mdf) has too high a moisture content, as the panel passes through the oven, the moisture is heated, generating steam causing significant coating finish issues.

Putting a coating to a concrete floor which is too damp can cause premature adhesion failure. Moisture meters have been developed to specifically determine the level of moisture in a substrate and come in two forms:

Pin-type moisture meters: Invasive pins are pushed firmly into the surface of the substrate being measured and by measuring the electrical resistance between the pin electrodes provide the percentage moisture content (%MC) in the substrate.

Pinless, contact-type moisture meters: Whilst pinless meters typically measure moisture content faster and are non-destructive they do require a relatively flat surface because the sensors are mounted on the base of the gauge making them ideal for concrete.

Available with pin probes only or pin probes with a non-invasive probe for non-destructive testing, the gauges give average moisture content by comparing the change in impedance between damp and acceptably dry substrates.

- Calibrated ready for use

- Instant readings on a clear, easy to read scale

- Fully portable, battery operated and non-destructive

|

Model |

Elcometer 7000PS Digital Moisture Meter |

|

Part Number |

G7000PS |

|

Measuring Range |

70 to 999 relative (non-invasive) |

|

Measurement Depth |

Non-invasive up to 19mm Pin up to 12.7mm |

|

Display |

LCD Display with separate colour indicators |

|

Dimensions |

190 x 70 x 49mm |

|

Weight |

225g |

|

Power Supply |

9V battery ( 20 hours continuous use) |

Precisely Monitor Concrete Moisture

Our Concrete Moisture Meter helps you easily detect moisture content in concrete, enabling better decisions for construction and flooring projects. With accurate readings, you can prevent moisture-related damage, ensuring your structures longevity.

Compact Design and User-Friendly Operation

Thanks to its compact dimensions (190 x 70 x 49 mm) and light weight (225 g), this meter can be conveniently handled and used in tight spaces. The simple manual control mode allows for straightforward moisture level checks, even for first-time users.

FAQs of Concrete Moisture Meter:

Q: How does the Concrete Moisture Meter work?

A: The Concrete Moisture Meter operates by detecting and displaying the moisture level in concrete when placed on the surface. Its manual control mode allows users to easily monitor readings on site.Q: What benefits does regular use of a moisture meter offer?

A: Regular use helps identify potential moisture problems early, preventing costly repairs or flooring failures due to trapped moisture, thus extending the life of your structures.Q: When should I use this meter during a construction project?

A: It is best used before, during, and after concrete curingespecially before applying finishes or flooring, to confirm that moisture levels are suitable and avoid adhesion issues.Q: Where can this device be effectively used?

A: This meter is ideal for construction sites, industrial floors, and anywhere accurate moisture detection in concrete is essential, thanks to its portability and effective design.Q: What is the recommended process for taking a measurement?

A: Simply place the meters sensors on the concrete surface, activate it using the manual controls, and note the displayed moisture reading. Ensure the surface is clean and free of debris for the most accurate result.Q: How does the device handle different environmental conditions?

A: The meter is designed to operate within a temperature range of 050C, making it suitable for most standard indoor and outdoor site environments across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Environmental Monitoring Instruments Category

Digital Hygrometer

Control Mode : Manual

Features : Portable, Wall Mountable, Compact Design

Mounting Type : Table/Wall Mounted

Measuring Range : 20% to 95% RH

Response Time : <10 seconds

Accuracy : 3% RH (Humidity), 1C (Temperature)

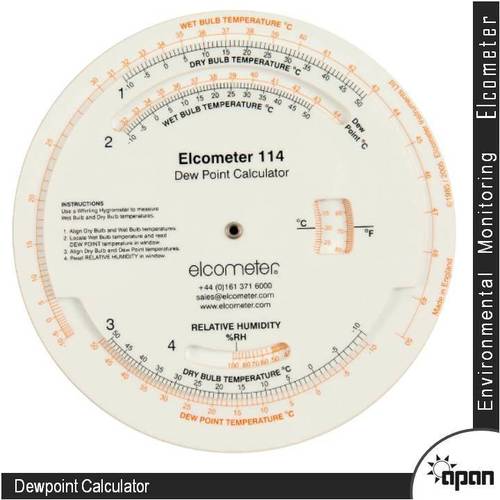

Dewpoint Calculator

Control Mode : Manual

Features : Portable, corrosion resistant, easy to operate

Mounting Type : Tabletop

Measuring Range : 80C to 0C (Dew Point)

Response Time : Less than 30 seconds

Accuracy : 1C

Hot Wire Anemometer

Control Mode : Manual

Features : Data hold, max/min/avg reading, backlit display

Mounting Type : Handheld

Measuring Range : 0.2 to 30.0 m/s

Response Time : 1 Second

Accuracy : 5% of reading

Grain Moisture Meter

Control Mode : Manual

Features : Portable, Direct Digital Reading, Low Battery Indicator

Mounting Type : Handheld

Measuring Range : 8% 40%

Response Time : Approx. 5 seconds

Accuracy : 0.5% moisture

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry