Digital Pulloff Adhesion Tester

Digital Pulloff Adhesion Tester Specification

- Display Type

- Digital LCD

- Accuracy

- 1% FS

- Interface Type

- USB (for data output)

- Power Supply

- Rechargeable Lithium Battery (7.4V 2200mAh)

- Specimen Size

- 20 mm, 50 mm or as specified

- Operating Voltage

- 7.4V DC

- Humidity

- 20%~85% RH (non condensing)

- Response Time

- <1 second

- Automation Grade

- Manual

- Mounting Type

- Manual, handheld

- Test Range

- 0~20 MPa

- Features

- Portable, digital display, battery operated, automatic peak hold, data storage

- Application

- Paint, coating, building material, cement, concrete, surface adhesion testing

- Port Size

- 1/4 inch NPT

- Max Height

- 230 mm

- Gas Pressure

- 0.4~0.7 MPa (for optional pneumatic models)

- Equipment Type

- Digital Pulloff Adhesion Tester

- Resolution

- 0.01 MPa

- Measuring Range

- 0~20 MPa

- Temperature

- 5C~40C

- Number of Specimens

- Single specimen per test

- Usage

- Adhesion pull-off strength measurement

- Capacity

- 20 kN (max)

- Machine Weight

- 2.6 kg (approx)

- Test Speed

- 0.05~5 MPa/s adjustable

- Test Width

- 50 mm standard (others optional)

- Test Stroke

- 90 mm max

- Control Mode

- Digital microprocessor based

- Data Storage Capacity

- Up to 250 test results

- Pull-Rate Control

- Programmable

- Compliance Standards

- ASTM D4541, ISO 4624

- Dolly Material Compatibility

- Steel, Aluminium

- Alarm Function

- Audio-Visual Overload

- Battery Life

- Approx. 8 hours continuous use

About Digital Pulloff Adhesion Tester

Various Types of Adhesion tester (Analog and Digital both types ) are available.

- Pull-Off Adhesion Testing

- Push Off Adhesion Testing

- Cross Hatch Adhesion Tester.

Pull-off Test

Adhesion of a single coating or a multi-coat system of paint, varnish or related products is assessed by measuring the minimum tensile stress necessary to detach or rupture the coating in a direction perpendicular to the substrate. This method maximizes tensile stress as compared to the shear stress put by other methods such as scratch adhesion and results may not be comparable. The test is performed by securing a loading fixture (dolly) perpendicular to the surface of the coating with an adhesive. After the adhesive is cured, a testing apparatus is attached to the loading fixture and aligned to put tension perpendicular to the test surface. The force put is gradually increased and monitored until either a plug of coating material is detached, or a specified value is reached.

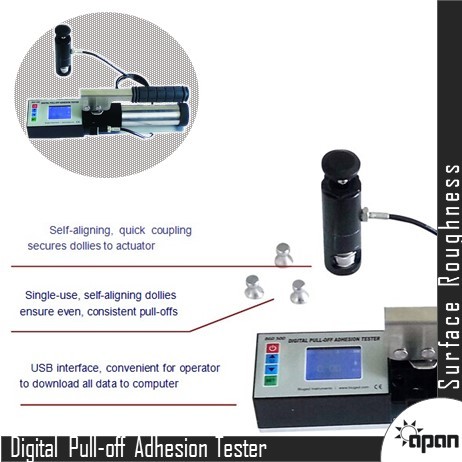

Digital pull-off adhesion tester is a portable, hand-operated instrument which is used to measure the force required to pull a specified test diameter of coating away from its substrate using hydraulic pressure.

The pressure is displayed on a digital LCD and represents the coatings strength of adhesion to the substrate.

It evaluates the adhesion (pull-offstrength) of a coating by determining the greatest tensile pull-off force that it can bear before detaching. Breaking points, demonstrated by fractured surfaces,occur along the weakest plane within the system consisting of dolly, adhesive,coating layers and substrate.

Advantage:

- Portable design, can be used anywhere.

- Built-in rechargeable lithium battery, no need any external power source.

- Selectable directly four different sizes dolly for different resolution and testing range

- Get the testing results from LCD directly.

PRECISE

- Each PsiaTesters pressure system is calibrated towithin 1% accuracy by NIST traceable load cells

- High-precise professional sensor ensures 0.01MPa resolution

- Self-aligning dollies ensure to get a reliable testing results for smooth or uneven surfaces.

- Supply with calibration certificate

INTELLIGENT

- Store all test results includes Max.pull-off power,pull-off rate, dolly size and timeautomatically

- Two units MPa and psifor selection and can be converted automatically.

- No need any software, when connecting the computer, operator can read all data directly which is recorded during testing.

- Showing pull-off rate allows users monitor and adjust pull speed according to different test requirements.

DURABLE

- Waterproof, dustproof and shockproof design meets any harshest operating environment

- Strong plastic carrying case

Specifications

- Dolly Size: 20mmStandard10mm14mm50mmOptional

- Resolution: 0.01MPa1psi

- Accuracy: 1% Full scale

- Max. Pull-off Pressure

- 10mm dolly 0-80 MPa

- 14mm dolly0-40 MPa

- 20mm dolly0-20 MPa

- 50mm dolly0-3.5 MPa

- PowerBuilt-in rechargeable lithium battery, and standard configuration charging adapter.

- Adhesion Tester Size360mm75mm115mmL x W x H

- Adhesion Tester Weight3KG

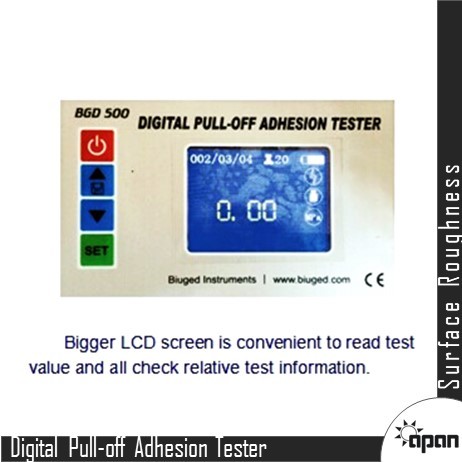

Advanced Data Storage & User-Friendly Operation

Store up to 250 test results within the device, allowing for efficient data analysis and record management. The USB interface ensures straightforward data transfer. Its intuitive digital controls and programmable pull-rate make it simple to set test parameters for different materials and standards. The LCD display provides instant access to measurements and test status.

Reliable Performance in Varied Environments

With compatibility for steel and aluminium dollies and adaptable test widths, the tester suits a broad range of surfaces and specimen sizes. The robust construction, rechargeable lithium battery, and lightweight design permit extended use even in field conditions. Operate reliably in environments from 5C to 40C and humidity levels of 20% to 85% RH (non-condensing).

Precision Testing for Multiple Applications

This tester is invaluable for measuring pull-off strength in applications like coatings, paints, cement, and concrete across quality control and research labs. Its high accuracy and programmable settings guarantee dependable results. Professionals benefit from compliance with ASTM and ISO standards, automated alert functions, and straightforward operation for consistent surface adhesion assessments.

FAQs of Digital Pulloff Adhesion Tester:

Q: How does the Digital Pulloff Adhesion Tester store and export test results?

A: The tester can store up to 250 test results internally. For external analysis, data can be easily exported via the built-in USB interface, making it convenient to transfer and maintain detailed records.Q: What types of materials and applications is this adhesion tester suitable for?

A: This equipment is compatible with steel and aluminium dollies and is engineered for testing paints, coatings, cement, concrete, and other building materials. It supports various specimen sizes, making it versatile for industrial and construction applications.Q: When should the programmable pull-rate feature be used?

A: Use the programmable pull-rate to match specific testing standards such as ASTM D4541 or ISO 4624, or to accommodate the characteristics of different substrates and coatings. This ensures more accurate and standard-compliant results.Q: Where can this tester be operated, considering environmental conditions?

A: It operates effectively in environments with temperatures between 5C and 40C and non-condensing humidity levels from 20% to 85% RH, making it suitable for both field and laboratory use.Q: What is the process for conducting an adhesion test with this device?

A: Begin by attaching the appropriate dolly (steel or aluminium) to the prepared specimen, set the desired test parameters using the digital controls, and initiate the test. The tester measures pull-off strength, displays the results on the LCD, and stores data for later review or export.Q: How does the alarm function alert users of potential issues during testing?

A: The audio-visual overload alarm alerts users if excessive force is applied or operational limits are exceeded. This enhances safety and prevents inaccurate results.Q: What are the main benefits of using this digital adhesion tester?

A: Benefits include high measurement accuracy, ease of use, robust compliance with international standards, efficient data storage, portability, and compatibility with a range of materials and test setups. These features support reliable, repeatable surface adhesion measurements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Inspection Category

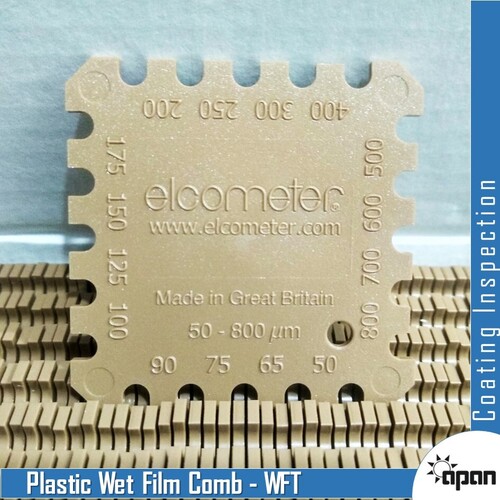

Plastic Wet Film Combs

Accuracy : 10 m

Usage : Industrial, laboratory, field

Display Type : Physical step gauge

Humidity : 0100% (ambient, nonsensitive)

Control Mode : Manual

Response Time : Immediate

Surface Profile Gauge

Accuracy : 0.01 mm

Usage : Surface profile measurement for quality control

Display Type : Analog (dial indicator)

Humidity : 2090% RH (operating)

Control Mode : Handheld

Response Time : Instantaneous

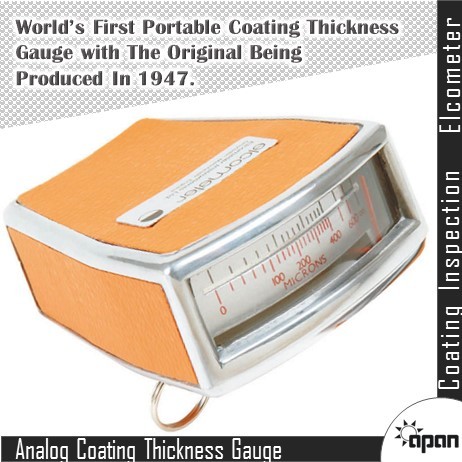

Analog Coating Thickness Meter

Accuracy : 2% of reading or 2 m (whichever is greater)

Usage : Coating thickness measurement

Display Type : Analog Dial Gauge

Humidity : 85% RH

Control Mode : Analog

Response Time : Instantaneous

Paint Inspection Gauge

Accuracy : 0.01 mm

Usage : Coating thickness inspection

Display Type : Dial gauge analog

Humidity : Up to 85% RH noncondensing

Control Mode : Manual

Response Time : Instantaneous

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry