Digital Schmidt Rebound Hammer

Digital Schmidt Rebound Hammer Specification

- Hardness

- 32 to 70 HRC

- Test Range

- 10 100 N/mm

- Interface Type

- USB, Bluetooth (optional)

- Resolution

- 0.1 N/mm

- Display Type

- Digital LCD

- Port Size

- Standard USB port

- Humidity

- 0% to 80% RH, non-condensing

- Automation Grade

- Semi-automatic

- Equipment Type

- Digital Schmidt Rebound Hammer

- Number of Specimens

- Single or batch mode

- Operating Voltage

- 5V DC USB charging

- Measuring Range

- 10 100 N/mm

- Specimen Size

- Cubic 150 mm, cylindrical 150 mm length

- Power Supply

- Rechargeable lithium-ion battery

- Mounting Type

- Handheld

- Response Time

- Immediate upon impact

- Accuracy

- 1 N/mm

- Temperature

- 0 C to 40 C

- Frequency

- Single impact per trigger

- Application

- Non-destructive testing of concrete compressive strength

- Max Height

- 185 mm

- Features

- Automatic recording, data storage, easy calibration, multiple language support

- Usage

- Concrete hardness measurement

- Capacity

- Up to 2000 readings

- Machine Weight

- Approx. 600 g

- Test Speed

- 0.8 m/s to 1.2 m/s

- Test Width

- Minimum 50 mm

- Test Stroke

- 75 mm

- Control Mode

- Manual

Digital Schmidt Rebound Hammer Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

About Digital Schmidt Rebound Hammer

As a Authorized dealer we are engaged in providing the broad assortment of Elcometer, UK make 'Concrete Inspection' Equipments.

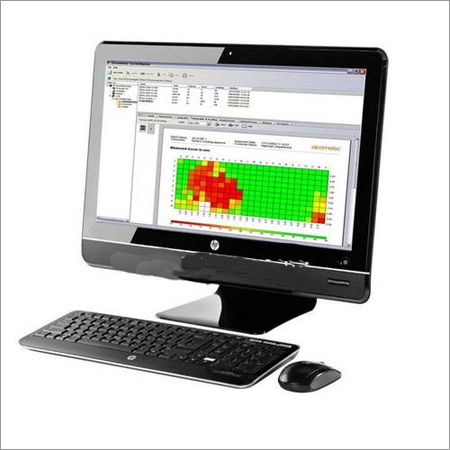

Elcometer 182 Digital Concrete Test Hammer is equipped with an electronic transducer which converts the rebound values into a reading on the digital display.

It displays a range of statistics and there is a facility to download to a PC.

The software and digital display are integrated into the design of the hammer.

Features

- Light and easy to use

- High resolution and accuracy

- Possibility to store measurements and download data to PC

- Setting of test parameters and factors (age, shape, correction factors)

- Rapid and simple calibration procedure

- Selection of testing angle

- Selection of unit (N/mm2, MPa, PSI, kgf/cm2) Automatic conversion of rebound index to equivalent compression strength

- Selection between 7 different correlation curves between rebound index and compressive strength, 2 pre-set and 5 user definable

- Statistical evaluation of test results (mean value, standard deviation, concrete strength estimation)

- Supplied with abrasive stone to prepare test surface

- Storage of up to 5,000 results

- RS 232 output to PC

- Rechargeable internal battery

Specification

Impact Energy | 2.207 Nm |

Accuracy | Better than ± 2 Rebound Number(s) (When tested on Calibration Anvil at 80) |

Resolution | 0.1 Rebound Number |

Range | 10 to 70 MPa |

Memory | 5000 tests |

Unit Selection | N/mm2; MPa; kg/cm2; PSI |

Autonomy (Continuous Use) | >5 Hours |

Dimensions | Hammer: 280mm (11.02") length x 55mm (2.17") diameter In Case: 190 x 100 x 350mm (7.48" x 3.94" x 13.78") |

Weight | 2kg (4.4lbs) with case |

Advanced Digital Precision

Experience highly accurate and repeatable results with 1 N/mm accuracy and real-time sampling. The digital interface enables instant feedback upon impact, ensuring efficiency and reliability during on-site concrete hardness assessments, whether for single samples or batch testing.

User-Friendly and Durable Design

With a compact build of 185 mm 65 mm 54 mm and weighing approximately 600 g, this hammer offers ergonomic handling for extended use. Its aluminum alloy construction and IP54-rated enclosure protect against dust and splashes, making it ideal for rigorous environments.

Comprehensive Data Management

Easily record and store up to 4,000 test results with automatic data logging. Data can be transferred via standard USB or wireless (Bluetooth optional), supporting seamless integration with analysis software. Multiple language support and clear digital readouts increase ease of use for diverse teams.

FAQs of Digital Schmidt Rebound Hammer:

Q: How is calibration performed on the Digital Schmidt Rebound Hammer?

A: This rebound hammer provides both automatic and manual calibration methods. Automatic calibration streamlines the setup process, while manual calibration enables verification and adjustment as needed using the included calibration anvil, ensuring ongoing measurement accuracy.Q: What are the benefits of digital data storage and transfer for this hammer?

A: With internal memory capable of storing up to 4,000 measurements, users can archive extensive test data. Data transfer via USB or optional wireless connectivity simplifies downloading and analysis, supporting efficient project documentation and reporting.Q: When should I utilize the batch testing mode?

A: Batch mode is ideal when multiple similar specimens require testingfor instance, during large-scale concrete structure assessments. This feature accelerates testing workflows by allowing consecutive measurements to be grouped and managed efficiently.Q: Where can the Digital Schmidt Rebound Hammer be used effectively?

A: Thanks to its IP54 dust and splash proof rating and operating temperature range from 0C to 40C, this device performs reliably on construction sites, in field environments, and indoor laboratories across diverse climatic conditions.Q: What process does the hammer follow to measure concrete strength?

A: The device impacts the concrete surface with predetermined energy (2.207 Joules), measuring the rebound value, which is displayed instantly. These values are used to estimate compressive strength via standardized correlation tables embedded in the systems software.Q: How does the device support multilingual teams?

A: The hammer offers easy-to-select language options, including English and other languages, streamlining operation and ensuring clear results for teams with diverse language requirements.Q: What advantages does the aluminum alloy and impact-resistant plastic body provide?

A: The combination of aluminum alloy and impact-resistant plastic ensures a lightweight yet robust structure, providing optimal protection against mechanical shocks and harsh conditions encountered during fieldwork.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Engineering Instrument Category

Cover Master Software

Features : Realtime Data, MultiLanguage, Data Export

Application : Cover Testing and Analysis

Control Mode : Digital Control

Temperature : 10C to 40C

Machine Weight : 25 kg

Accuracy : 0.5%

Rebar Detector

Features : Portable, Lightweight, Audible & Visual Alarm, Data Storage, Backlit Display

Application : Locating and measuring rebar in concrete structures

Control Mode : Microcontroller Based

Temperature : 10C to 40C

Machine Weight : 1.5 kg

Accuracy : 1 mm for depth measurement

Stud Locator

Features : Auto Calibration, AC Wire Detection, Low Battery Indicator

Application : Detecting studs in walls (wood, metal, AC wires)

Control Mode : Automatic / Manual

Temperature : 10C to 50C

Machine Weight : Approx. 150 g

Accuracy : 1 mm

Cover meter

Features : Rebar location, cover depth, easy operation, portable

Application : Detecting rebar position and cover thickness in concrete

Control Mode : Handheld, direct operation

Temperature : 10C to 50C

Machine Weight : 2.3 kg

Accuracy : 1 mm (typical)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry