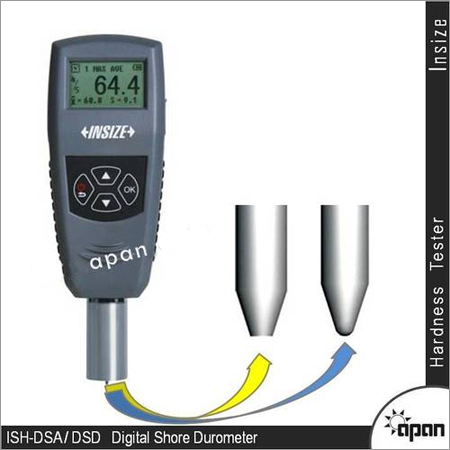

Digital Shore Durometer

Digital Shore Durometer Specification

- Operating Voltage

- 3 V (2x1.5V batteries)

- Response Time

- Immediate, < 1 sec

- Specimen Size

- Minimum thickness 6 mm

- Application

- Shore hardness testing of rubber, plastics, and soft materials

- Temperature

- 0C to 40C operating range

- Power Supply

- 2 x 1.5V AAA Batteries

- Display Type

- LCD Digital Display

- Humidity

- 85% RH (non-condensing)

- Mounting Type

- Handheld

- Features

- Portable, digital display, automatic shutdown, peak hold

- Automation Grade

- Manual

- Hardness

- Shore A, 0-100

- Resolution

- 0.1 HA

- Interface Type

- None (standalone unit)

- Accuracy

- 1% FS

- Measuring Range

- 0-100 HA

- Test Range

- 0-100 HA (Shore A)

- Number of Specimens

- Single specimen at a time

- Equipment Type

- Digital Shore Durometer

- Usage

- Surface hardness measurement

- Capacity

- Standard Shore A hardness range

- Machine Weight

- Approx. 200 g

- Test Speed

- Manual, instant measurement

- Test Stroke

- 3 mm (typical range within indentation)

- Control Mode

- Digital, automatic readout

- Calibration

- Factory calibrated, calibration block optional

- Color

- Silver/Black

- Battery Life

- Up to 100 hours continuous use

- Backlight Display

- Yes

- Data Hold Function

- Yes

- Material

- ABS Plastic housing, metal probe tip

- Auto Power Off

- Yes

- Dimensions

- 150 mm x 50 mm x 30 mm

- Probe Type

- Spring-loaded indenter needle

- Operating Principle

- Indentation method as per DIN 53505, ASTM D2240 standards

About Digital Shore Durometer

Digital Shore Durometer for testing the hardness of rubbers, elastomers and plastics. Available in Shore A for softer rubbers and Shore D for harder plastics, resins etc.

Digital Durometers are designed for easy use to test most soft rubbers and elastomers, through to hard plastics and resins.

Common applications are for quality control purposes and include testing the hardness of skateboard wheels, car tyres, shoe soles, gummy bears and cheeses to name just a few. A durometer measures the resistance to an indentation that is made with a specific indenter and spring loading according to specific test standards such as ASTM D 2240. When measuring for QC, a durometer is used to measure for consistency in a product and that it meets internal specification requirements.

The unit is fully integrated to be simply used with one hand operation and shows live statistics on its screen. Including the current hardness result, minimum, maximum, average values and standard deviation.

To use the DSD you press the device onto the surface of the object under evaluation, and based on the resistance to the spring loading it displays a reading on the screen in the shore scale relevant to the device that you have. The most common scales are Shore A for soft rubbers and Shore D for harder plastics. There are other specialised scales available which we can assist with.

FEATURES:

- Live statistics - average, min, max, standard deviation

- Instant printing of results to wireless, mini printer (optional extra)

- Easy saving of test data to large internal memory (500 readings)

- Ultra compact, lightweight and ergonomic for easy use

- Mountable in test stand for controlled load application and dwell time (optional extra)

- Rechargable internal battery

The standard kit includes the unit, power adapter, calibration control ring and factory calibration certificate. Optional extras are reference test blocks, wireless printer and test stand.

Specification

Scale | Shore A | Shore D | |

Accuracy | 1 HA / HD | ||

Resolution | 0.1 HA / HD | ||

Display | LCD (backlit) | ||

Memory | 500 readings | ||

Power | Ni-MH internal, rechargable | ||

Data Output | 2.4G wireless printer (Optional) | ||

Dimensions | 150mm x 50.5mm x 29mm | ||

Weight | 170g | ||

Precise and Reliable Hardness Measurement

Engineered to deliver immediate results, this Digital Shore Durometer utilizes the indentation method with a spring-loaded indenter, ensuring compliance with DIN and ASTM standards. Its high-resolution LCD display and 1% full-scale accuracy make it suitable for rigorous quality control and research tasks in diverse industries.

User-Friendly Design for Practical Applications

Lightweight and portable, this durometer weighs approximately 200 grams and fits comfortably in hand for single-specimen measurements. An automatic power-off feature conserves battery life, while the digital display can be backlit for clarity in low-light environments, making it suitable for onsite or laboratory testing.

FAQs of Digital Shore Durometer:

Q: How do I operate the Digital Shore Durometer for accurate measurements?

A: To use the durometer, place the probe perpendicularly on a clean specimen with a minimum thickness of 6 mm, press down manually to allow the indenter to penetrate the material, and read the result on the digital LCD display. Ensure steady pressure and consistent test speed for best accuracy.Q: What materials is this durometer suitable for testing?

A: This device is specifically designed for Shore A hardness testing on rubber, soft plastics, elastomers, and similar flexible materials, making it an ideal tool for quality assessment in manufacturing, R&D, and material inspection.Q: When should I recalibrate or use a calibration block with this durometer?

A: The instrument is factory calibrated for precision. However, for critical use or after significant usage, optionally verify calibration with a reference block or seek professional calibration services to maintain accuracy.Q: Where can I use the durometer, considering environmental conditions?

A: The durometer can be operated in environments with a temperature range from 0C to 40C and humidity up to 85% RH (non-condensing). It is best suited for workshop, laboratory, or field testing where these conditions are met.Q: What is the process for replacing the batteries, and how long do they last?

A: The device operates on two 1.5V AAA batteries, which are easily replaced by opening the battery compartment. It offers up to 100 hours of continuous usage, thanks to its auto power-off feature that helps conserve energy.Q: How is the data hold function used during hardness measurement?

A: The data hold function allows you to freeze and record the hardness value displayed, making it easy to document or compare results without losing readings during specimen handling or data entry.Q: What are the main benefits of using this digital durometer over analog models?

A: This digital model provides immediate, high-resolution (0.1 HA) readings, automatic power management, a handy backlit LCD, and eliminates the parallax error found in analog units. Its portability and accuracy streamline the testing process, capable of serving distributors, exporters, and laboratories throughout Iceland.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Automatic Rockwell Hardness Tester

Resolution : 0.1 HR

Automation Grade : Automatic

Hardness : Rockwell HRA, HRB, HRC scales

Usage : Rockwell hardness testing of metals and alloys

Accuracy : 1.5% of reading

Measuring Range : 20 100 HRA, 20 100 HRB, 20 70 HRC

Digital Micro Vickers Hardness Tester

Resolution : 0.01 HV

Automation Grade : Semiautomatic

Hardness : 1 3000 HV

Usage : Vickers and Knoop hardness testing

Accuracy : 1.0%

Measuring Range : 1 3000 HV

Digital Rockwell & Superficial Hardness Tester

Resolution : 0.1 HR

Automation Grade : SemiAutomatic

Hardness : Rockwell, Superficial Rockwell

Usage : Hardness Testing of Metals

Accuracy : 1 HR

Measuring Range : HRB, HRC, HR15N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W

Manual Digital Rockwell Hardness Tester

Resolution : 0.1 HRC

Automation Grade : Manual

Hardness : Rockwell C (HRC) scale

Usage : Industrial, Laboratory

Accuracy : 1%

Measuring Range : 20~100 HRC (Rockwell C)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry