Double-Geo Haze Gloss Meter

Double-Geo Haze Gloss Meter Specification

- Equipment Type

- Portable Gloss Meter

- Accuracy

- 1 GU (Gloss), 0.1% (Haze)

- Number of Specimens

- Single

- Response Time

- 2 seconds

- Measuring Range

- Gloss: 0-200 GU; Haze: 0-30%

- Temperature

- 0C to 40C

- Mounting Type

- Handheld

- Humidity

- 85% RH (non-condensing)

- Specimen Size

- 60 mm x 40 mm minimum

- Display Type

- Digital LCD

- Test Range

- 0-200 GU (Gloss Units)

- Power Supply

- DC 6V (4 x AA batteries)

- Features

- Dual Geometry (20, 60), Haze Measurement, Portable, Data Hold

- Resolution

- 0.1 GU, 0.01% (Haze)

- Automation Grade

- Manual

- Port Size

- Standard

- Application

- Measurement of surface gloss and haze in coatings, plastics, and glass

- Interface Type

- USB

- Operating Voltage

- 6V

- Usage

- Surface gloss and haze evaluation

- Machine Weight

- Approx. 1.2 kg

- Test Speed

- Manual

- Test Width

- 60 mm

- Test Stroke

- Customizable

- Control Mode

- Digital

About Double-Geo Haze Gloss Meter

Poor product formulation or polishing effects leading to a drop in surface quality can quickly be identified using the Double-Geo Haze Glossmeter

- Calculates haze to ASTM D 4039

- Measures using the 60 geometry

- Measures using the 20 geometry

- Haze measurement Modefor BGD 519/2

- Calibrate automatically.

- Statistical analysis for 10 group data

- USB Connection

Main Technical Parameters

- Reading Range0.099.9GU200.099.9GU20

- 1002000GU201001000GU20

- Data repeatability0.2GU0~99.9GU0.2%100~1999GU

- Data quantitative repeatability0.5GU0~99.9GU0.5%100~1999GU

- Windows Size1152mm

- The size of measuring aperture1010mm201020mm60

- Confirm StandardASTM D 4039ISO 2813ASTM D523

- Dimensions144mmL64mmH 32mmD

Versatile Dual-Angle Gloss and Haze Measurement

The Double-Geo Haze Gloss Meter allows users to measure surface gloss at both 20 and 60 angles, as well as haze up to 30%. This dual functionality helps professionals assess the visual and optical properties of surfaces, ensuring quality across coatings, plastics, and glass products.

User-Friendly Calibration and Spacious Data Storage

Calibrating the device is simple with the included standard calibration plate, guaranteeing consistent accuracy. The gloss meter can store up to 1000 readings, enabling users to manage extensive datasets for quality control, record keeping, or analysis without frequent data transfers.

Portable, Efficient, and Compliant

Weighing approximately 1.2 kg and powered by four AA batteries, the meter is lightweight and portable, suitable for on-site and laboratory settings. It complies with major standards like ASTM D523 and ISO 2813, and provides results in less than 2 seconds, combining efficiency with trusted performance.

FAQs of Double-Geo Haze Gloss Meter:

Q: How do I calibrate the Double-Geo Haze Gloss Meter before starting measurements?

A: Calibration is straightforward using the standard calibration plate included with the device. Simply follow the instructions in the user manual to ensure the gloss meter is set to deliver accurate readings every time you use it.Q: What surfaces and sample sizes can the meter evaluate for gloss and haze?

A: The meter is suitable for measuring gloss and haze on coatings, plastics, and glass. It accommodates samples with a minimum size of 60 mm x 40 mm and thicknesses up to 10 mm, making it versatile for various industrial applications.Q: When should I use the 20 versus the 60 geometry angle setting?

A: Use the 20 geometry for highly glossy surfaces and the 60 setting for medium to low gloss areas. This dual-geometry approach provides accurate measurement across a broad range of surface gloss levels, following ASTM D523 and ISO 2813 standards.Q: Where can I store or transfer my measurement data from the gloss meter?

A: The device holds up to 1000 readings, which can be reviewed on its digital LCD. For further analysis or reporting, simply transfer your data to a computer using the built-in USB interface.Q: What is the process for taking continuous versus single measurements?

A: Single measurement mode captures one reading per action, ideal for spot checks. Continuous mode collects multiple sequential results quickly, suitable for scanning larger surfaces or obtaining more comprehensive gloss and haze profiles.Q: How can the gloss meter benefit quality control in manufacturing or exporting?

A: Accurate gloss and haze measurement ensures product consistency and compliance with industry standards, reducing the risk of quality-related returns or complaints during distribution, export, or supply operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Optical Instrument Category

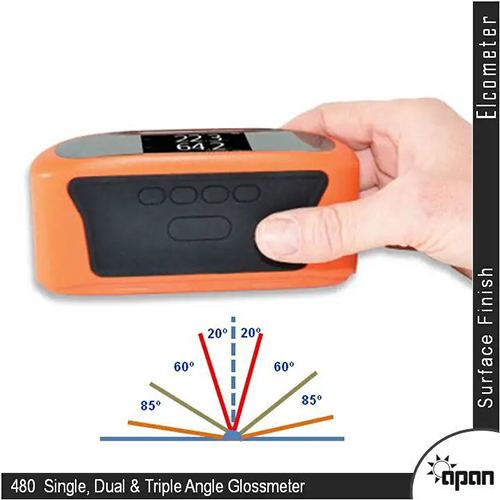

Elcometer 480 Glossmeter

Accuracy : 1.2 GU (0100 GU range at 60)

Response Time : Immediate, within 2 seconds

Display Type : High resolution color LCD display

Features : Auto calibration, date/time stamp, large memory, ergonomic design, multilingual support

Automation Grade : Manual

Application : Measuring surface gloss of paints, coatings, plastics, metals, wood, etc.

Color spectrophotometer

Accuracy : E*ab 0.04

Response Time : <1 second

Display Type : Color LCD Display

Features : Portable, High accuracy, Multiple color space data output, Data storage, Calibration function

Automation Grade : Semiautomatic

Application : Color measurement of solids, powder, textiles, paints, plastics, paper, and other materials

Light Transmittance Meter

Accuracy : 1%

Response Time : <1 sec

Display Type : LCD digital

Features : Portable, easy operation, robust design

Automation Grade : Semiautomatic

Application : Glass, plastic, film, transparent materials

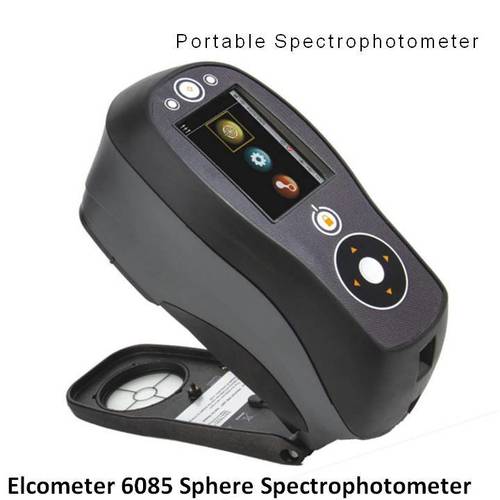

Sphere Spectrophotometer

Accuracy : E*ab0.02 (measurement condition: calibration plate after calibration, measurement mode: SCI, 23C2C, relative humidity 085%)

Response Time : Within 1.5 seconds

Display Type : Color touchscreen

Features : SCI/SCE measurement, automatic calibration, portable design

Automation Grade : Automatic

Application : Color measurement, quality control, laboratory analysis

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry