Novo Curve Glossmeter

Novo Curve Glossmeter Specification

- Display Type

- LCD digital display

- Power Supply

- 2 x AA Batteries

- Features

- Memory storage, PC connectivity, lightweight, portable, automatic calibration

- Specimen Size

- Minimum radius: 5mm (concave and convex); Max curvature: 40mm

- Response Time

- < 2 seconds

- Mounting Type

- Handheld

- Accuracy

- 1 GU (0100 GU); 1% (1012000 GU)

- Equipment Type

- Glossmeter

- Resolution

- 0.1 GU

- Interface Type

- USB

- Humidity

- 0 85% RH (non-condensing)

- Application

- Measurement of gloss on curved surfaces

- Test Range

- 0 2000 GU

- Operating Voltage

- 3V (2 x AA Batteries)

- Temperature

- 15 40C operating

- Automation Grade

- Manual

- Measuring Range

- 0 2000 Gloss Units

- Number of Specimens

- Single at a time

- Usage

- Non-destructive gloss measurement

- Machine Weight

- 800g

- Control Mode

- Manual

- Compliance

- ASTM D523, ISO 2813 and relevant standards

- Battery Life

- Approx. 10,000 readings per set

- Instrument Body Material

- High-impact ABS plastic

- Dimensions

- Height: 70mm, Width: 155mm, Depth: 45mm

- Calibration

- Automatic calibration using supplied tile

- Data Output

- USB connection to PC

- Memory Capability

- Stores 200 readings

- Measurement Geometry

- 60° Angle

- Instrument Finish

- Matte Black

Novo Curve Glossmeter Trade Information

- Main Export Market(s)

- Asia

About Novo Curve Glossmeter

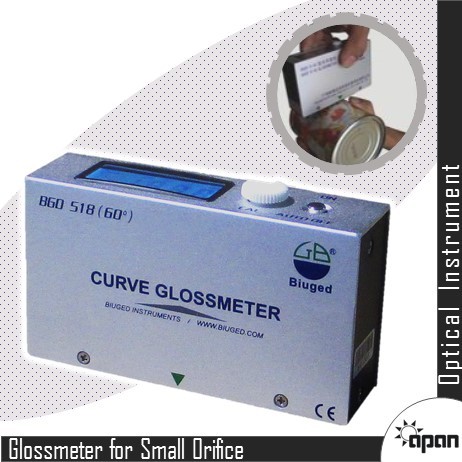

Novo-Curve Glossmeter

As a Authorized dealer we are engaged in providing the broad assortment of wide gamut of optical instruments.Increasingly, specifications and standards require an assessment of gloss. Gloss measurement is necessary to monitor the uniformity, compatibility, or possibly the deterioration of any protective gloss finish. Using the 4 adjustable posts and the small measurement area, the Elcometer 400 is perhaps the only glossmeter designed specifically for measuring covered surfaces, small components and complex shapes. Continuous reading mode allows the rapid assessment of finish variation.

No need to wait for data to download, the LCD screen displays screen index, maximum temperature & graphical representation for each probe. Measures a whole range of products and designs - including:

- Paint finish

- Wood Varnish

- Automobile parts: Trim, steering wheel, dashboard

- Glazed Ceramics

- Frosted Glass

- Large digital clear and easy to read display giving meaningful readings

- Non-destructive gloss measurement

- Measurement of 60 degrees ASTM Gloss optimized for small areas from low gloss or matt to high gloss

- Fully Statistical model

- Continuous function enables user to "SCAN" the product quickly

- 300 measurement Memory

- Foot Switch for two hand operation

- Data Output to Computer

- Full Statistics: Mean, SD, CV

- 4 Jigging Posts to help in repeatably positioning an item

- Optional Jig for repeatably placement of 5mm to 150mm radius cylinders

Specification

| Aperture | 4.5mm dia |

| Weight | 2.5 kg |

| Standards | ASTM D523, ISO2813 |

| Measurement Range | 60 Degree: 0 - 1000 GU |

| Memory | 199 readings |

| Power Supply | 110 - 120V AC or 220 - 240V AC |

| Spot | 2 x 2mm |

| Dimensions | 160mm x 220mm x 100mm |

Precision Gloss Measurement for Curved Surfaces

Novo Curve Glossmeter offers industry-leading gloss measurement specifically designed for curved surfaces such as coatings, plastics, and automotive parts. With its single-specimen capacity and ability to handle concave and convex radii as small as 5mm, this handheld device is optimized for versatility across numerous applications, providing accurate and consistent readings with minimal effort.

Effortless Calibration and Data Management

Automatic calibration with the supplied reference tile ensures reliable performance and accuracy before each session. The built-in memory stores up to 200 gloss readings, which you can easily export via USB to a PC for data analysis and reporting, streamlining both quality control and record-keeping.

User-Friendly, Portable, and Sturdy

Crafted from high-impact ABS plastic, the glossmeter stands up to demanding environments while maintaining a lightweight and compact form. Its powered by two AA batteries, offering approximately 10,000 readings per set, and operates reliably in varied humidity and temperature conditions, making it suitable for field and laboratory use.

FAQs of Novo Curve Glossmeter:

Q: How do I calibrate the Novo Curve Glossmeter?

A: Calibration is completely automatic. Simply use the supplied calibration tile as instructed in the manualplace the instrument on the tile and it will initiate and complete the calibration sequence automatically, ensuring precise results every time.Q: What types of curved surfaces can the glossmeter measure?

A: The Novo Curve Glossmeter can measure gloss on both concave and convex surfaces with a minimum curvature radius of 5mm and a maximum curvature of 40mm. This versatility makes it ideal for evaluating gloss on various manufactured items, including automotive components and molded plastics.Q: When should I use the memory storage function?

A: Utilize the memory storage feature to save up to 200 readings during inspection or quality control processes. This function is particularly beneficial when you need to record results from multiple tests before transferring the data to your PC for analysis or archiving.Q: Where can the Novo Curve Glossmeter be used?

A: This device is suitable for use in laboratories, manufacturing plants, and field environments. It is extensively used by distributors, exporters, suppliers, and traders across India for gloss measurement in coatings, finishes, and production quality checks.Q: What is the process for retrieving stored data from the glossmeter?

A: To access stored readings, connect the glossmeter to a PC using the built-in USB interface. Data can then be exported directly for further processing, analysis, and documentation, simplifying report generation and compliance tracking.Q: How long does the battery last, and what are the power requirements?

A: Powered by two AA batteries, the Novo Curve Glossmeter delivers approximately 10,000 readings per set. This longevity ensures uninterrupted testing during extended fieldwork or busy production schedules.Q: What are the main benefits of using the Novo Curve Glossmeter?

A: Key benefits include precise, repeatable measurements on curved surfaces, quick automatic calibration, large memory for multiple readings, user-friendly interface, robust build for frequent handling, compliance with international standards, and efficient data transfer via USB.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Optical Instrument Category

Gloss Meter for Curve Surface

Automation Grade : SemiAutomatic

Usage : Surface gloss measurement on nonflat objects

Application : Measuring gloss on curved, cylindrical, or irregular surfaces

Response Time : <1 second

Mounting Type : Handheld

Display Type : Digital LCD Display

Digital Colorimeter

Automation Grade : SemiAutomatic

Usage : Analytical laboratory, research, industrial QC

Application : Used for color analysis of liquids in lab and industry

Response Time : Less than 2 seconds

Mounting Type : Benchtop

Display Type : Digital LCD

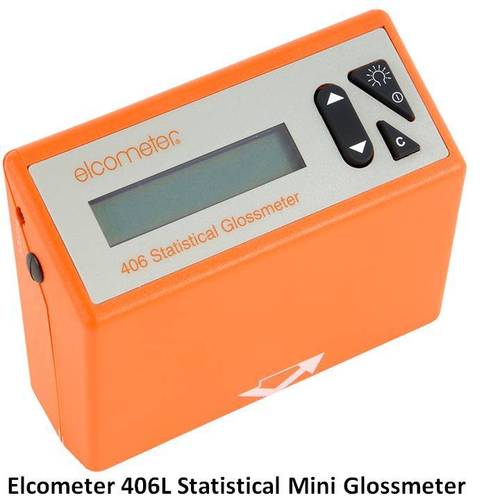

Statistical Mini Glossmeter

Automation Grade : Manual

Usage : Laboratory and Field

Application : Gloss measurement of coatings, paints, plastics

Response Time : <1 second

Mounting Type : Handheld

Display Type : Digital LCD Display

Economy Gloss Meter

Automation Grade : Manual

Usage : Measure Gloss levels

Application : Measuring gloss level of painted, coated and polished surfaces

Response Time : 1 second

Mounting Type : Handheld

Display Type : Digital LCD display

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry