Bridge Cam Gauge

Bridge Cam Gauge Specification

- Hardness

- Stainless Steel (Approx. HRC 40-45)

- Max Height

- 60 mm

- Application

- Weld measurement, Inspection of fillet, throat, angle, misalignment, weld size, etc.

- Display Type

- Engraved Scale (Analog)

- Number of Specimens

- Single Measurement at a Time

- Accuracy

- 0.1 mm

- Interface Type

- Manual/Analog - No Digital Interface

- Automation Grade

- Manual

- Features

- Multi-parameter measurement, Corrosion-resistant stainless steel, Portable, Easy-to-read scales, Durable

- Humidity

- Standard Lab Conditions

- Resolution

- 0.1 mm

- Power Supply

- Not Required (Manual Tool)

- Test Range

- 0-60 mm (Height Gauge), 0-25 mm (Fillet Weld Gauge)

- Mounting Type

- Handheld

- Measuring Range

- 0-60 mm (Various Gauges Provided)

- Temperature

- Standard Lab Conditions

- Response Time

- Immediate (Manual Tool)

- Specimen Size

- Compatible with Welds and Plates up to 60 mm

- Usage

- Welding Inspection, Fabrication, Construction, Quality Control

- Capacity

- Measures multiple weld characteristics

- Machine Weight

- Approx. 75 g

- Control Mode

- Manual

- Degree Measurement

- Angle Measurement up to 60°

- Profile Gauge Capability

- Measures convexity/concavity of weld bead

- Finish

- Brushed / Satin

- Ideal For

- Inspection in shipbuilding, pressure vessels, pipelines, structural steel works

- Package Contents

- Bridge Cam Gauge, Protective Case, Instruction Manual

- Units of Measurement

- Metric (mm) and Imperial (inch)

- Corrosion Resistance

- Yes

- Material

- Stainless Steel

- Equipment Type

- Bridge Cam Gauge

Bridge Cam Gauge Trade Information

- Main Export Market(s)

- Asia

About Bridge Cam Gauge

The material of the gauge is high strength stainless steel, then the ruler is not easy to bend and wear, never rust and it also ensure accurate measurement. Weld inspection ruler with fastening screws can be fixed at any point, then it is convenient for reading when you do the measurement the ruler surface is mechanical grinding, no glitches.

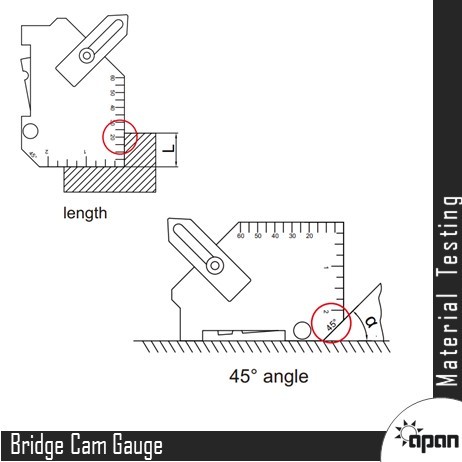

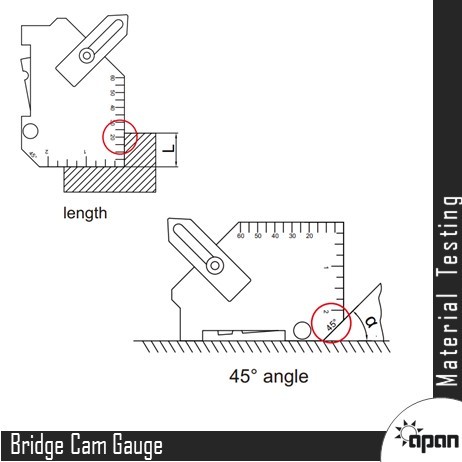

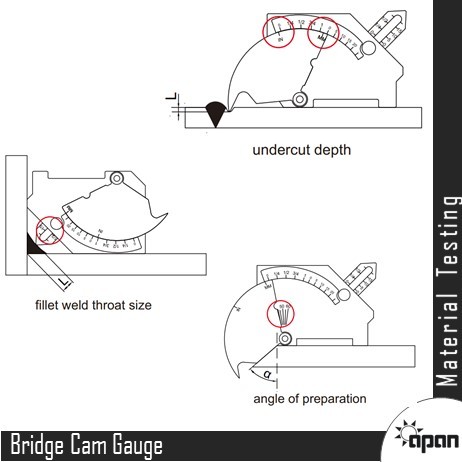

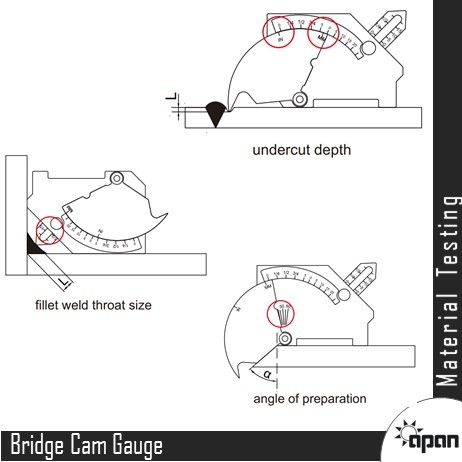

An essential tool for rapidly checking the dimensions of weld preparations, butt welds and fillet welds -

- angle of preparation

- misalignment

- fillet weld leg length/excess weld metal

- fillet weld throat

- undercut

Used across the world by welding engineers, inspectors, NDT operators, quality control staff and welders.

Made of stainless steel

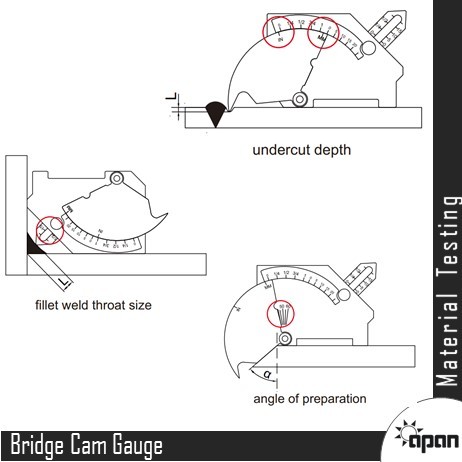

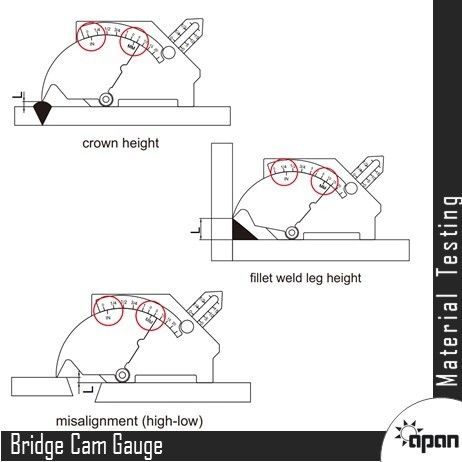

- Used for measurement: Crown height, fillet weld leg height, misalignment (high-low), undercut depth, fillet weld throat size, angle of preparation, length.

- This tough, easy-to-use gauge is made from stainless steel throughout and finished to a high standard. Its parallax-free scales are conveniently graduated in metric and imperial units.

- Ideal for general fabrication work in the shop or on-site, it helps you achieve the correct weld profile, reduce the risk of product failures, increase productivity and prevent materials wastage.

FAQs

What is the use of bridge cam gauge?

The Bridge Cam Gauge, also referred to as the Cambridge gauge, is a reliable, precise gauge that may be used in the shop or on the job site. It can gauge the thickness of the throat and legs of the fillet welds, the height of the weld reinforcement, the depth of the undercut, the misalignment, and the preparation angle.wear, increased expenditures for upkeep, and, at its

Does thickness increase with gauge?

A sheet metal measure (at times spelled gage) demonstrates the standard thickness of sheet metal for a particular material. As the check number builds, the material thickness diminishes.

Do weld gauges need to be calibrated?

The actual welding force at the weld is precisely measured by a weld force gauge. These instruments must be calibrated since using a weld force that is either too low or too high might result in issues including cracking, indentation, ejection, and weak welds.wear, increased expenditures for upkeep, and, at its

Versatile Weld Inspection Tool

Designed for accuracy and convenience, this Bridge Cam Gauge allows professionals to measure a broad range of weld characteristics, including weld bead convexity or concavity, fillet size, throat thickness, angle, and misalignment. Its integrated analog scale supports both metric and imperial units, accommodating diverse industry needs. Highly portable and easy to use, it fits perfectly into welding inspection workflows.

Durable and Corrosion-Resistant Design

Manufactured from brushed stainless steel, the gauge boasts excellent durability and corrosion resistance, suitable for tough jobsite and workshop conditions. The engraved scales are clear and easy to read, ensuring measurement reliability. With hardness rated at approximately HRC 40-45, you can rely on its long service life and robust performance during repeated inspections.

Manual Control and Instant Readings

This manual bridge cam gauge operates without power supply, delivering immediate, accurate readings. Its analog interface and engraved scale provide reliable results without the need for batteries or digital interfaces, making it especially effective for fieldwork and challenging environments where electricity may not be readily available.

FAQs of Bridge Cam Gauge:

Q: How do I use the Bridge Cam Gauge for weld inspection?

A: To use the Bridge Cam Gauge, place it against the weld or plate surface and align the relevant scale to measure parameters such as fillet size, throat thickness, angle (up to 60), or misalignment. The engraved analog scales display measurements instantly in both metric (mm) and imperial (inch) units. Consult the instruction manual included for step-by-step guidance.Q: What types of weld measurements can the Bridge Cam Gauge perform?

A: This gauge can measure convexity and concavity of weld beads, fillet and throat dimensions, weld angles (up to 60), weld misalignment, and general weld size. It covers a measurement range of 060 mm (height) and 025 mm (fillet), enabling multiple weld characteristics to be checked in one tool.Q: When should I use this gauge in my workflow?

A: Use the Bridge Cam Gauge during welding inspection, fabrication, construction, or quality control tasks. It is especially valuable after weld completion to verify adherence to specifications in industries like shipbuilding, pipelines, structural steel, and pressure vessel manufacturing.Q: Where is the Bridge Cam Gauge best applied?

A: This tool is ideal for applications in shipyards, construction sites, fabrication workshops, and any setting where inspection of welds on plates and structures up to 60 mm is required. Its portable design supports both on-site and lab-based use.Q: What is the process for maintaining the Bridge Cam Gauge?

A: To ensure accuracy and longevity, keep the gauge clean and dry after use. Store it in the included protective case to prevent surface damage and exposure to contaminants. Periodically wipe with a soft cloth and avoid excessive force to maintain engraved scale visibility and precision.Q: What benefits does the Bridge Cam Gauge offer over digital gauges?

A: Unlike digital gauges, the Bridge Cam Gauge provides immediate readings without batteries or external power, ensuring reliability even in remote locations. Its robust stainless steel construction resists corrosion and physical wear, while the analog scales are always legible, making it a dependable tool for frequent fieldwork.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Metrology Tools Category

Metrology Instruments

Machine Weight : Approx. 45 kg

Usage : Lab and Industrial Measurement

Application : Material Testing, Dimensional Measurement

Test Range : 0500 mm

Features : Automatic Data Logging, Overload Protection, Programmable Test Cycles

Humidity : 85% RH

Digital Height Gauge with Driving Wheel

Machine Weight : Approx. 5.5 kg

Usage : Workshop, quality inspection, laboratory

Application : Height measurement of components

Test Range : 0300 mm, 0600 mm, 01000 mm (depending on model)

Features : Zero setting, metric/inch conversion, driving wheel, locking screw, fine adjustment

Humidity : 85% RH

Digital Height Gauge

Machine Weight : Approx. 2.5 kg

Usage : Height measurement & Scribing

Application : Measuring height and marking of components

Test Range : 0300 mm

Features : Zero setting, Metric/Inch conversion, Data hold, Fine adjustment

Humidity : 80% RH

Elcometer Weld Gauge

Machine Weight : Approx. 50g

Usage : Weld Inspection

Application : Measures weld throat thickness, leg length, angle and misalignment

Test Range : Measurement of weld features

Features : Compact, portable, easytouse, corrosion resistant material

Humidity : 090% RH (Operating Conditions)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry