Cover meter

Cover meter Specification

- Specimen Size

- Standard concrete structures

- Measuring Range

- 0~180 mm (cover depth)

- Resolution

- 1 mm

- Automation Grade

- Manual

- Features

- Rebar location, cover depth, easy operation, portable

- Response Time

- Instantaneous

- Application

- Detecting rebar position and cover thickness in concrete

- Number of Specimens

- Single-point or mapping

- Power Supply

- Rechargeable Li-ion battery / 230V AC adapter

- Interface Type

- USB/RS232 (model dependent)

- Display Type

- LCD digital display

- Humidity

- < 95% RH non-condensing

- Test Range

- Up to 180 mm (cover depth)

- Mounting Type

- Handheld

- Frequency

- 50/60 Hz

- Operating Voltage

- Rechargeable battery / 230V AC

- Accuracy

- 1 mm (typical)

- Temperature

- -10C to 50C

- Usage

- Non-destructive testing of reinforced concrete

- Capacity

- Measures cover, bar diameter, bar location

- Machine Weight

- 2.3 kg

- Test Speed

- Manual scanning

- Test Width

- Up to 180 mm cover

- Control Mode

- Handheld, direct operation

- Alarm

- Visual & audio alert for minimum cover

- Equipment Type

- Digital Cover Meter

- Data Storage

- Internal memory, 100,000 readings

- Sensor Technology

- Pulse induction electromagnetic sensor

- Compliance Standard

- Meets ASTM C876, BS1881 Part 204

- Display Backlight

- Yes, adjustable brightness

- Carrying Case

- Rugged carrying case with accessories

- Charging Time

- Approx. 4 hours

- Protection Class

- IP54

- Battery Life

- Up to 10 hours continuous use

- Language Support

- Multilingual display options

- Calibration

- Factory calibrated, user calibration available

Cover meter Trade Information

- Main Export Market(s)

- Asia

About Cover meter

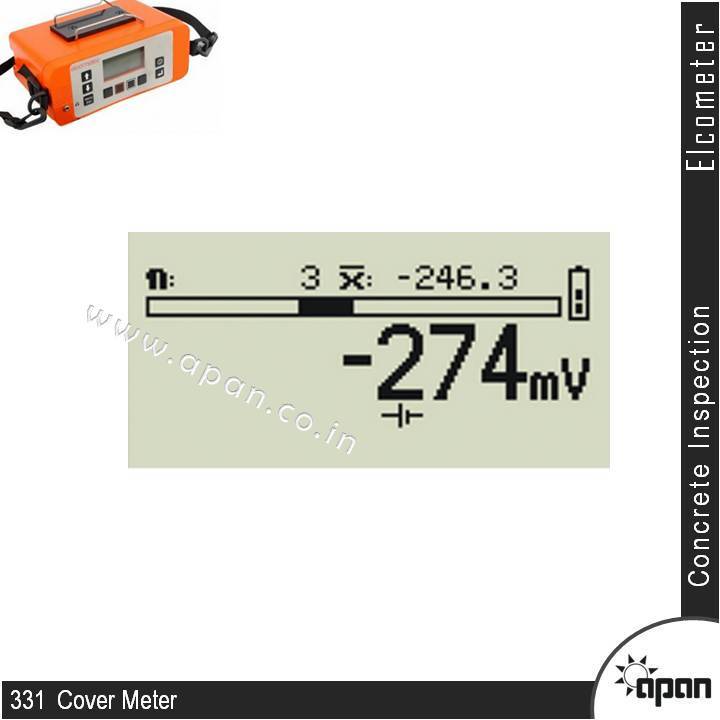

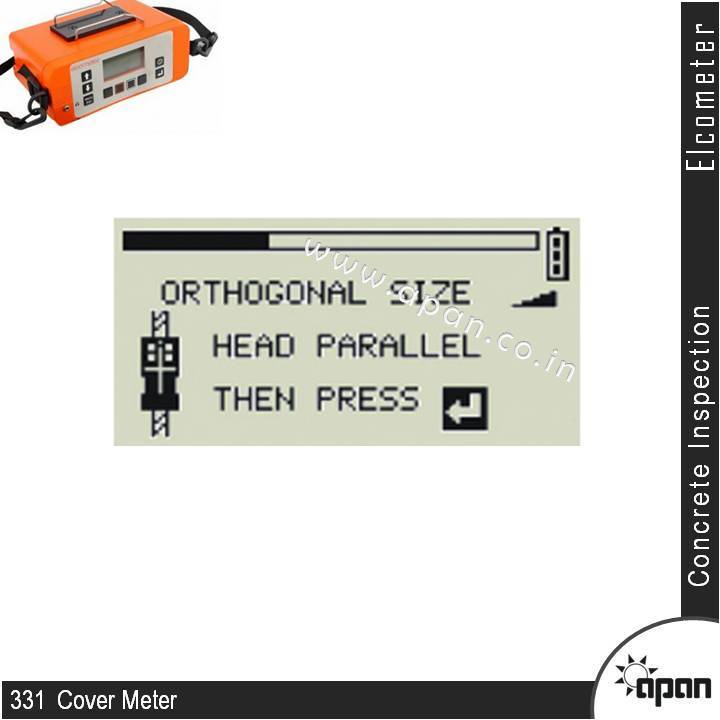

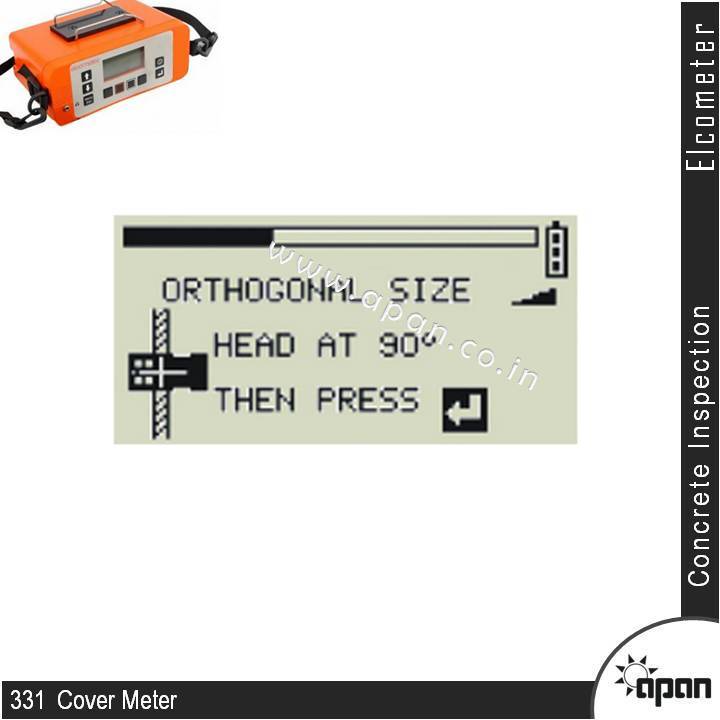

As a Authorized dealer we are engaged in providing the broad assortment of Elcometer, UK make 'Concrete Inspection' Equipments. Elcometer 331, Model B Covermeter is easy to use cover meter quickly and accurately locates, orientates and measures the depth of cover over reinforcement bars.

Designed to meet IP65 this rugged waterproof cover meter can be used in the harshest of environments.

- Fast and accurate: Locate and determine orientation of rebar quickly, easily & accurately.

- Large, easy to read backlit display: For easy viewing in dark environments.

- Interchangeable search heads: Select from standard search head, narrow pitch search head, deep cover search head and borehole probe.

- Single handed operation: Most functions can be accessed & controlled through 4 simple keys.

- Intuitive menus in multiple languages: Allows use straight out of the box

- International bar sizes : User selectable bar sizes include metric, US Bar Numbers, ASTM/Canadian and Japanese for use anywhere in the world.

- Rechargeable battery supply: Battery packs can be charged inside or outside the gauge.

- Ergonomically shaped case: For ease of use and comfort, with a gentle curve to fit snugly against the hip

Features :

- Covermeter /rebar location

- Rebar orientation

- Depth of cover

- Large cover (thickness) reading mm or inches

- Large graphics display with backlight

- Multiple language menu structure

- Signal strength bar

- Interchangeable heads with LED & keypad

- User selectable bar range sizes & numbers

- Rugged waterproof case (IP65)

- Adjustable beep volume & earphone socket

- Measurement sound modes :Locate (tone increases as head approaches rebar)

- Large half cell reading mV

FAQs

What is the purpose of cover meter?

An tool called a cover metre is used to find rebars and determine the precise concrete cover. The less sophisticated rebar detectors can only find metallic items below the surface. Due to the cost-effective design, the pulse-induction method is one of the most commonly used solutions.

What are the factors that affect cover meter measurement?

Cover measurement is often influenced by neighbouring bars (i.e. parallel bars that are close to the one being measured). The study's bars were spaced 100mm apart. Since cover measurement accuracy will increase if bar spacing increases, this study does not include other bigger bar spacing.

Advanced Sensing and Accurate Measurement

Leveraging pulse induction electromagnetic sensors, this cover meter accurately detects rebar position, diameter, and concrete cover depth up to 180 mm. With an impressive accuracy of 1 mm and instant response time, users can rely on dependable measurements for a wide variety of concrete structures, ensuring safety and compliance with ASTM C876 and BS1881 part 204 standards.

User-Friendly Design with Enhanced Mobility

Designed for portability, the handheld device weighs only 2.3 kg and features intuitive, direct operation controls. The adjustable LCD backlight and multilingual options ensure comfortable use in diverse conditions. The rugged carrying case protects the system and all accessories for effortless transport and durability on job sites.

Efficient Operation and Data Management

This cover meter streamlines data collection with manual scanning capabilities and automatic data storage of 100,000 readings in internal memory. Data transfer options via USB or RS232 (model dependent) simplify integration with reporting systems, making it ideal for professionals who require detailed record-keeping and efficient workflow management.

FAQs of Cover meter:

Q: How does the cover meter detect rebar position and depth in concrete?

A: The cover meter uses pulse induction electromagnetic sensor technology to non-destructively locate rebar embedded within concrete structures and measure both its position and the cover depth, with high accuracy up to 180 mm.Q: What is the process for using the digital cover meter on-site?

A: Simply switch on the handheld device, calibrate if needed, and scan the concrete surface manually. The sensor instantly displays rebar location, cover depth, and diameter on the backlit LCD. Alarms will notify users if minimum cover is not met.Q: When should I calibrate the cover meter, and is user calibration possible?

A: The device arrives factory calibrated for convenience, but user calibration is available for site-specific accuracy. Calibration should be performed before use in new environments or if measurement drift is suspected.Q: Where can I use this cover meter, considering environmental conditions?

A: With an IP54 rating, the meter is suitable for indoor and outdoor use, resistant to dust and water splashes, and functions reliably in temperatures from -10C to 50C and up to 95% relative humidity (non-condensing).Q: What are the benefits of its internal memory and connectivity features?

A: The internal memory stores up to 100,000 readings, allowing efficient data logging across large projects. USB or RS232 interfaces (model dependent) enable seamless data transfer to computers or reporting systems for further analysis.Q: How long can I use the cover meter on a single battery charge?

A: A fully charged Li-ion battery supports up to 10 hours of continuous use, and the device recharges in approximately 4 hours, reducing downtime and ensuring efficiency.Q: What types of concrete specimens or applications are suitable for this cover meter?

A: It is ideal for standard concrete structures, supporting both single-point measurement and mapping for comprehensive assessment of rebar placement and cover thickness in construction, inspection, and quality control projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Engineering Instrument Category

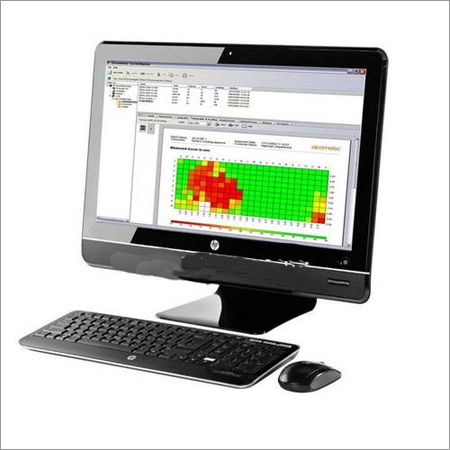

Cover Master Software

Control Mode : Digital Control

Measuring Range : Wide

Machine Weight : 25 kg

Automation Grade : Fully Automatic

Resolution : 0.01

Features : Realtime Data, MultiLanguage, Data Export

Digital Schmidt Rebound Hammer

Control Mode : Manual

Measuring Range : 10 100 N/mm

Machine Weight : Approx. 600 g

Automation Grade : Semiautomatic

Resolution : 0.1 N/mm

Features : Automatic recording, data storage, easy calibration, multiple language support

Stud Locator

Control Mode : Automatic / Manual

Measuring Range : 038 mm

Machine Weight : Approx. 150 g

Automation Grade : Manual

Resolution : 1 mm

Features : Auto Calibration, AC Wire Detection, Low Battery Indicator

Rebar Cover Meter Accessories

Control Mode : Manual

Measuring Range : Dependent on instrument, generally up to 100 mm

Machine Weight : 350 g (approx.)

Automation Grade : Manual

Resolution : 0.1 mm

Features : Nondestructive testing, Durable, Precise alignment

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry