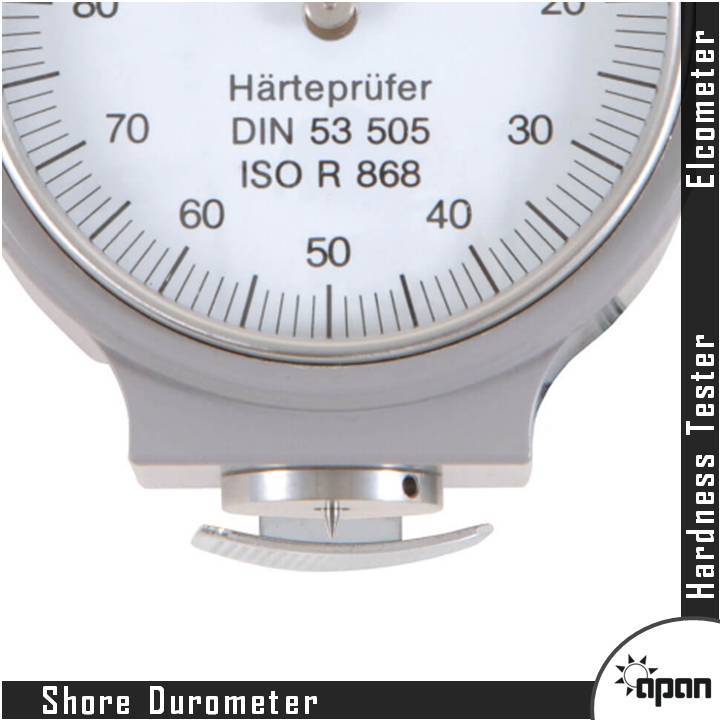

Elcometer Shore Durometer

Elcometer Shore Durometer Specification

- Humidity

- 0 - 80% RH (Non-condensing)

- Accuracy

- 1 Shore unit

- Response Time

- Immediate

- Specimen Size

- Minimum size: 6 mm thickness

- Measuring Range

- 0-100 Shore units

- Number of Specimens

- Single specimen per test

- Mounting Type

- Handheld

- Automation Grade

- Manual

- Hardness

- 0 to 100 Shore A (or D)

- Application

- Measurement of hardness of rubber, plastic and other non-metallic materials

- Test Range

- 0 to 100 Shore A / D (model dependent)

- Resolution

- 1 Shore unit

- Equipment Type

- Handheld Shore Durometer

- Display Type

- Analog analog dial

- Features

- Portable, analog dial, easy to operate

- Temperature

- 0C to 50C

- Power Supply

- Not required (manual operation)

- Usage

- Hardness testing of non-metallic materials

- Capacity

- Standard durometer capacity

- Machine Weight

- 200g (approx.)

- Test Speed

- Manual, hand-pressed

- Test Width

- Applicable for various specimen widths

- Test Stroke

- Standard single stroke

- Control Mode

- Analog

Elcometer Shore Durometer Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

About Elcometer Shore Durometer

As a Authorized dealer we are engaged in providing the broad assortment of "Hardness Tester" includes table top and Portable type. The Elcometer 3120 range of Shore A and Shore D Durometers is widely used to test the hardness of soft materials.

A round point indents the material under a fixed force spring and the hardness is displayed on the dial in Shore Hardness Units.

The instrument can be used either hand-held or fitted to an optional stand for increased repeatability.

Various options

- Elcometer 3120 Shore Durometer A

- Elcometer 3120 Shore Durometer A with Max indicator

- Elcometer 3120 Shore Durometer A with Max indicator and 10N weight

- Elcometer 3120 Shore Durometer D

- Elcometer 3120 Shore Durometer D with Max indicator

Precision Hardness Measurement

The Elcometer 313 is engineered for rigorous hardness testing in quality control and R&D environments. Its analog display provides instant readings across Shore A and D scales, suitable for a wide range of rubber and plastic specimens. Compliance with international standards ensures dependable and comparable results every time.

Reliable and Ergonomic Operation

With its lightweight anodized aluminum body and ergonomic grip design, the Elcometer 313 offers comfortable single-handed operation. The manual, hand-pressed measurement process demands no power supply, making the unit highly portable for both field and laboratory use.

Comprehensive Application Suitability

Designed for versatility, this durometer accommodates specimens of various widths with a minimum thickness of 6 mm. Its standard stroke and analog control make it simple to operate for both novice and experienced users engaged in material testing and hardness classification.

FAQs of Elcometer Shore Durometer:

Q: How do I use the Elcometer 313 Shore Durometer correctly?

A: To use the Elcometer 313, place it firmly against the surface of your specimen ensuring minimum thickness of 6 mm. Apply a steady, uniform pressure manually with a single smooth stroke to obtain an immediate reading on the analog dial. Avoid multiple strokes to maintain accuracy.Q: What industries and applications is the Elcometer 313 suitable for?

A: This durometer is ideal for quality control, material testing, and research laboratories, especially in the rubber and plastics industry. It is also widely used by exporters, suppliers, traders, and wholesalers for quality assurance of non-metallic materials.Q: When should I consider recalibrating the Elcometer 313?

A: The instrument is factory calibrated and ready to use upon delivery. However, for sustained accuracy, periodic verification using calibration blocks or standards according to your quality protocols is recommended, especially after extended use or accidental dropping.Q: Where can the Elcometer 313 be used given its operating conditions?

A: Due to its portability and manual operation, the Elcometer 313 can be used both in laboratories and on-site, provided the environment stays within 0 to 50C temperature and 0-80% non-condensing relative humidity.Q: What is the process for taking hardness measurements with this device?

A: Place the durometer vertically on the test specimen ensuring only the indentor touches the surface. Press the device downward manually until it sits flat, then read the hardness value shown on the analog dial. One test per specimen is recommended to avoid inconsistencies.Q: What are the key benefits of the Elcometer 313 durometers design?

A: With its ergonomic, anodized aluminum construction and no dependence on batteries or external power, the durometer is both comfortable to use and highly portable. Its analog display offers immediate, precise hardness values, simplifying onsite and laboratory testing workflows.Q: How does the measuring range differ between Shore A and Shore D models?

A: The Shore A model measures soft to medium hardness materials like rubber, while the Shore D model measures harder plastics. Both models cover a full 0 to 100 Shore unit range, selectable based on your specific testing requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Digital VickersHardness Tester

Machine Weight : Approx. 40 kg

Test Speed : Adjustable, standard 0.05 mm/s

Application : Hardness testing for metals, alloys, and other materials

Display Type : Digital LCD with Backlight

Resolution : 0.1 HV

Temperature : 10C 35C

Linear Abrasion Tester

Machine Weight : Approx. 40 kg

Test Speed : 0~60 cycles/min, adjustable

Application : Assessment of abrasion resistance for coated, painted, and printed surfaces

Display Type : Digital display (LCD)

Resolution : 1 cycle

Temperature : Room temperature (5C ~ 35C)

Portable Hardness Tester

Machine Weight : 1.5 kg

Test Speed : Standard, per ASTM E110

Application : Onsite metal hardness testing

Display Type : LCD digital display

Resolution : 1 HL

Temperature : 0C to 50C

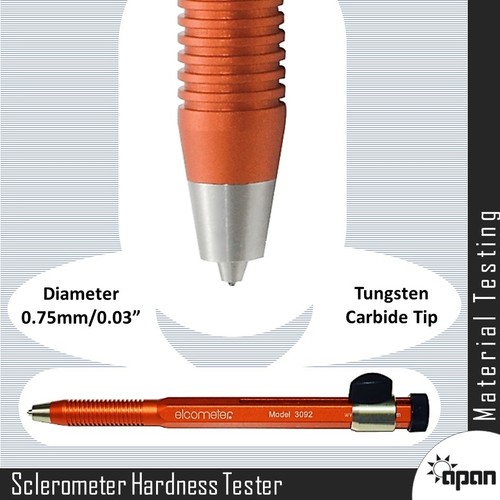

Sclerometer Hardness Tester

Machine Weight : 370g Gram (g)

Test Speed : Manual

Application : Hardness Testers

Display Type : Analog

Resolution : 0.1 HV

Temperature : 5C 40C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry