Rebar Detector

Rebar Detector Specification

- Frequency

- 50-60 Hz

- Accuracy

- 1 mm for depth measurement

- Display Type

- Digital LCD Display

- Power Supply

- Rechargeable Battery (7.4V, 2200 mAh)

- Equipment Type

- Handheld Rebar Detector

- Operating Voltage

- 7.4V DC

- Measuring Range

- 6-50 mm (Rebar Diameter), 1-100 mm (Rebar Cover Depth)

- Max Height

- Handheld, not applicable

- Mounting Type

- Handheld

- Humidity

- 90% RH

- Interface Type

- USB

- Response Time

- Instantaneous (<1s)

- Resolution

- 0.1 mm

- Number of Specimens

- Multiple (Sequential Scan)

- Port Size

- Standard USB Charging Port

- Automation Grade

- Semi-Automatic

- Temperature

- -10C to 40C

- Test Range

- Rebar diameter 6-50 mm, depth up to 100 mm

- Features

- Portable, Lightweight, Audible & Visual Alarm, Data Storage, Backlit Display

- Application

- Locating and measuring rebar in concrete structures

- Specimen Size

- Concrete 300 mm thickness

- Usage

- Non-destructive testing, construction inspection

- Capacity

- Suitable for large surface area

- Machine Weight

- 1.5 kg

- Test Speed

- Manual Scanning

- Test Width

- Up to 70 mm per scan

- Test Stroke

- Continuous

- Control Mode

- Microcontroller Based

- Charging Time

- Approx. 3 hours

- Sensor Type

- Electromagnetic Induction

- Battery Operating Time

- 6-8 hours continuous use

- Data Storage Capacity

- Up to 200 groups of data

- Alarm Method

- Sound and Light

- Material Compatibility

- Concrete, mortar

- Protection Level

- IP54 Dust and Splash Proof

- Included Accessories

- Carrying Case, Charger, User Manual

Rebar Detector Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

About Rebar Detector

As a Authorized dealer we are engaged in providing the broad assortment of Elcometer, UK make 'Concrete Inspection' Equipments. The Elcometer P120 Rebar Locator provides a simple means to detect reinforcement bars in concrete, identifying the rebars location, direction and an indication of the depth of concrete over the rebar.

- Supplied together with a 100mm (4) search coil, leather carry case and batteries the Elcometer P120 is available in both metric and imperial versions.

- Fast, accurate and stable - Loud audio tone and clear analogue meter, with no need to re-zero the instrument during use

- High resolution controlled field search head - The strongest signal is in the centre of the search head making it accurate even when working at very close reinforcement bar centres or near metal objects, e.g. close to scaffolding or metal window frames

- Versatile - Supplied with a standard 100mm (4) head it will also accept a 150mm (6) head and a Borehole Probe for locating rebars and locating tendon ducts at great depths

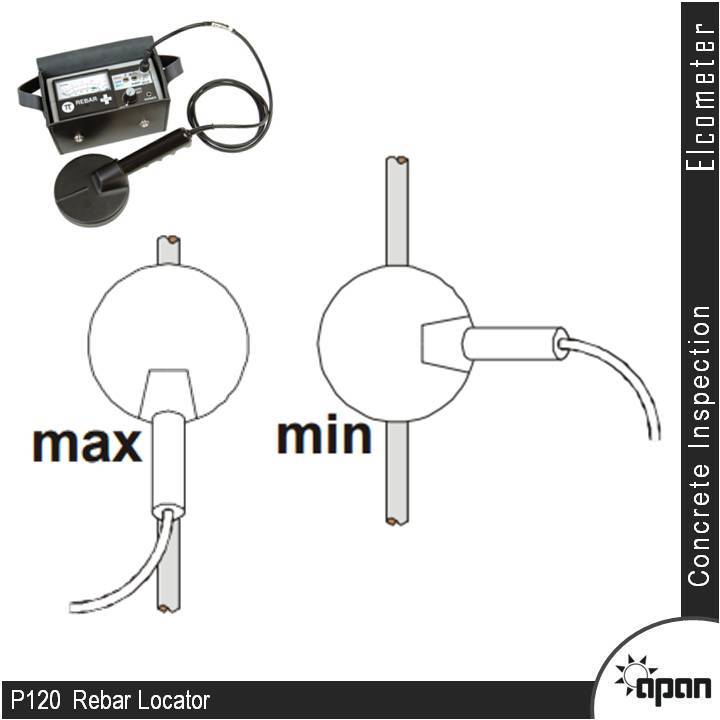

- Rebar Plus rebar locators can quickly and easily distinguish between horizontal and vertical bars due to their highly directional detection field

- Clear Instrument Display - High quality meter shows signal strength and battery state

- Headphone socket - Clearly detect the rebar in noisy environments

Identification and Orientation of the bar :

The Elcometer P120 can distinguish between horizontal and vertical bars. After locating the steel reinforcement bars in the concrete, rotate the rebar locators search coil (probe) until the maximum and minimum signals are found. The maximum signal indicates the bar is running parallel to the search coils handle, the minimum signal indicates that the bar is running at 90° to the search coils handle

SEARCH HEAD ORIENTATION

Despite having a circular face, the search head is in fact directional and has a sensitive axis running across the face parallel to the line of the handle. The relative orientation of this axis to the line of the rebar affects the signal strength, and it is by this means that the direction of a rebar can be determined, and complex structures resolved.

Efficient Rebar Detection in Concrete Structures

This rebar detector offers a reliable solution for construction professionals who need precise and rapid assessment of internal rebar placement in concrete and mortar. Its electromagnetic induction-based sensor delivers immediate and accurate results, facilitating safe and effective inspection without damaging the material. The device can scan large surface areas, making it ideal for structural analysis on major projects.

Convenient Data Management and User Experience

Designed with portability and usability in mind, this detector stores up to 200 groups of test data, allowing users to track and review multiple specimens sequentially. The backlit digital LCD display, combined with audible and visual alarms, guides the user throughout manual scanning. With a rechargeable battery lasting up to 8 hours and fast USB charging, this tool supports uninterrupted workflows on site.

FAQs of Rebar Detector:

Q: How does the electromagnetic induction sensor work in this rebar detector?

A: The electromagnetic induction sensor detects the presence and position of rebar by emitting an electromagnetic field and measuring the disturbance caused by metal within concrete or mortar. This allows for accurate, non-destructive location and sizing of rebars.Q: What is the procedure for scanning and storing rebar data with the device?

A: Users manually scan concrete surfaces with the handheld detector. During each scan (up to 70 mm wide), the device instantly displays results on the LCD and stores up to 200 groups of measurements for later review, ensuring reliable documentation of construction inspections.Q: When should this rebar detector be used on site?

A: This detector is ideal before drilling or coring concrete, during routine inspections, or whenever precise placement or cover depth of rebar needs verification in buildings, bridges, or other structures, ensuring safety and structural integrity.Q: Where is the rebar detector most compatible and useful?

A: It is compatible with concrete and mortar surfaces up to 300 mm thick, making it highly useful on construction sites, quality control labs, and infrastructure projects requiring large area scans and accurate rebar mapping.Q: What benefits does the IP54 protection level provide during operations?

A: The IP54 dust and splash proof rating safeguards the detector against harsh site conditions, ensuring consistent performance and durability in environments with high dust concentration or occasional water splashes.Q: How long can the device operate and how is it powered?

A: Powered by a rechargeable 7.4V, 2200mAh battery, the detector operates continuously for 68 hours. Recharging takes about 3 hours via the provided USB charging port, supporting extended use throughout the workday.Q: What makes this device suitable for various construction professionals in India?

A: Its portable, lightweight design, combined with automatic data storage, alarm functions, and compatibility with both small and large concrete specimens, makes it an essential tool for distributors, suppliers, engineers, and quality inspectors across the construction industry.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Engineering Instrument Category

Wall Tie Locator

Test Range : 0 100 kN

Features : Portable, robust design, easy operation

Application : Locating and testing wall ties in masonry

Usage : Industrial, construction site

Specimen Size : Standard (Wall Tie dimensions)

Humidity : Up to 95% RH

Digital Schmidt Rebound Hammer

Test Range : 10 100 N/mm

Features : Automatic recording, data storage, easy calibration, multiple language support

Application : Nondestructive testing of concrete compressive strength

Usage : Concrete hardness measurement

Specimen Size : Cubic 150 mm, cylindrical 150 mm length

Humidity : 0% to 80% RH, noncondensing

Concrete Test Hammer

Test Range : 1070 N/mm (MPa)

Features : Portable, easy to use, no battery required

Application : Nondestructive testing of concrete compressive strength

Usage : Surface hardness measurement for concrete/rock

Specimen Size : Tested surface should be at least 150 mm 150 mm

Humidity : 90% RH

Stud Locator

Test Range : Up to 19 mm (Wood Stud) / 38 mm (Metal Stud)

Features : Auto Calibration, AC Wire Detection, Low Battery Indicator

Application : Detecting studs in walls (wood, metal, AC wires)

Usage : Wall Stud Detection

Specimen Size : Universal, Suitable for Various Wall Types

Humidity : Up to 85% RH (Noncondensing)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry