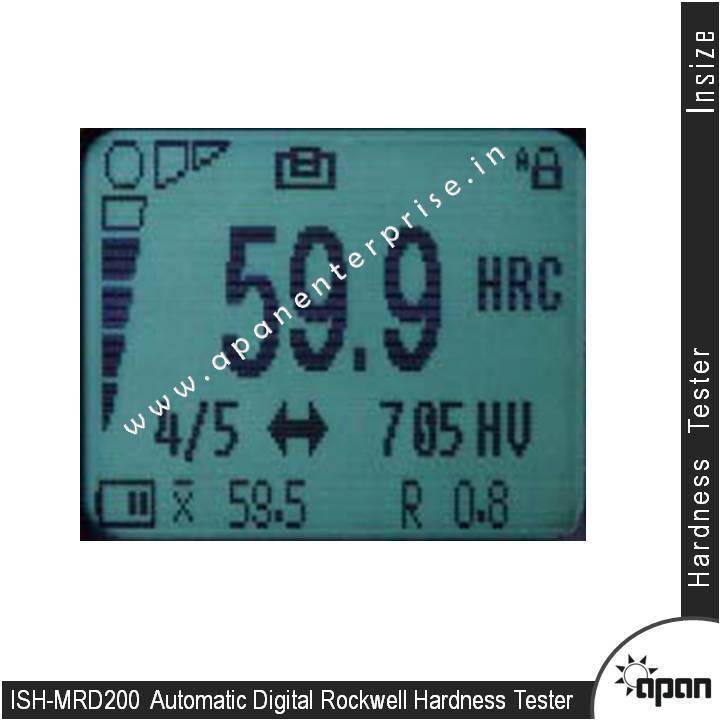

Automatic Digital Rockwell Hardness Tester

Automatic Digital Rockwell Hardness Tester Specification

- Features

- Automatic loading/unloading, digital display, memory, data output

- Number of Specimens

- Multiple consecutive tests possible

- Power Supply

- AC 220V 10%, 50Hz

- Application

- Metals, alloys, heat-treated materials hardness testing

- Interface Type

- RS232

- Measuring Range

- 20-100 HRA/HRB, 20-70 HRC

- Temperature

- 10C ~ 35C

- Specimen Size

- 2~70 mm (height)

- Frequency

- 50 Hz

- Automation Grade

- Automatic

- Equipment Type

- Automatic Digital Rockwell Hardness Tester

- Resolution

- 0.1 HR

- Operating Voltage

- 220V AC

- Display Type

- Digital LCD

- Mounting Type

- Benchtop

- Port Size

- Standard

- Hardness

- Rockwell (HRA, HRB, HRC)

- Humidity

- 85% RH

- Response Time

- Instantaneous upon test

- Accuracy

- 1 HR

- Test Range

- 20~100 HRA, 20~100 HRB, 20~70 HRC

- Max Height

- 180 mm

- Usage

- Laboratory/industrial material hardness measurement

- Capacity

- Large testing capacity

- Machine Weight

- 95 kg

- Test Speed

- 50~60 tests/hour

- Test Width

- 150 mm (max distance from indenter center to body)

- Test Stroke

- 180 mm

- Control Mode

- Automatic digital

Automatic Digital Rockwell Hardness Tester Trade Information

- Main Export Market(s)

- Asia

About Automatic Digital Rockwell Hardness Tester

We are counted among the topmost suppliers of a wide range of Automatic Digital Rockwell Hardness Tester. In accordance with industry standards, this is manufactured using high grade materials. Our highly skilled team procures the entire stock from genuine vendor in market. We are offering this equipment to clients in different specifications at economical prices. Automatic Digital Rockwell Hardness Tester is specifically designed for measuring the hardness of different kinds of metals and alloys.

Features:

- High level of accuracy in result

- User friendly design

- Fully automatic operation

Advanced Display and Data Management

The digital LCD provides real-time feedback on the testing process, displays critical information like error codes, and supports statistical memory for multiple test data. Integrated memory storage ensures important test results are securely retained, and RS232 output allows for seamless data export to external devices for further analysis and documentation.

Versatile and Efficient Testing

Capable of handling a large range of specimen sizes (270 mm in height) and test types, the tester operates with automatic or manual scale selection across HRA, HRB, and HRC ranges. The automatic motorized indenter and rapid test cycle (up to 60 tests/hour) enhance throughput and reduce user intervention, making it ideal for high-volume testing environments.

Reliability and Precision Guaranteed

With an accuracy of 1 HR and repeatability of 1 HR, the tester ensures highly reliable results. Its robust build, LED indicators, and stringent environmental adaptability (up to 85% RH, 1035C) maintain performance in demanding laboratory and industrial settings. Multi-language support broadens accessibility and usability for diverse operator expertise.

FAQs of Automatic Digital Rockwell Hardness Tester:

Q: How does the Automatic Digital Rockwell Hardness Tester ensure measurement accuracy and repeatability?

A: The tester is designed with precision penetrators (diamond cone and steel ball) and a motorized automatic indenter to maintain consistent test forces and conditions. It provides an accuracy of 1 HR and repeatability of 1 HR, minimizing user-dependent variability and ensuring reliable, reproducible results across multiple tests.Q: What types of test scales and penetrators does this instrument support?

A: This model supports Rockwell HRA, HRB, and HRC scales with automatic or manual selection. The available penetrator types include a diamond cone for harder materials and a steel ball for softer metals and alloys, enhancing versatility in hardness determination for various material types.Q: When can I use the memory storage and data output functions?

A: Memory storage is automatically engaged with every test, saving multiple consecutive results and statistical summaries. For external documentation or further analysis, you can use the RS232 output to transfer data to a printer or a PC at any time during or after testing.Q: Where is this device most suitable for use?

A: Thanks to its bench-mounted design, robust construction, and large capacity, the tester is ideal for laboratory and industrial environments. Common applications include quality control, research and development, and production line materials verification, especially in metal and alloy industries.Q: What is the process for operating this automatic hardness tester?

A: The operating process involves placing the specimen, selecting the appropriate scale (automatic or manual), and initiating the testing sequence. The device automatically loads the penetrator, applies the force, measures the indentation, displays the result, and archives the data, streamlining the workflow for the user.Q: How does the multi-language support benefit diverse user teams?

A: With both English and Chinese language options available on the digital display, the tester is accessible to multilingual teams, reducing the learning curve and enhancing efficiency for operators across different regions and backgrounds.Q: What are the main advantages of using this automatic digital Rockwell hardness tester over manual models?

A: The automatic digital model minimizes human error, increases throughput (up to 60 tests/hour), automates loading/unloading, provides instant digital results, and allows for seamless data storage and transfer. These features lead to improved workplace efficiency, accurate documentation, and greater ease of operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Tablet Hardness Tester

Control Mode : Manual

Specimen Size : Diameter 220 mm

Machine Weight : Approx. 5 kg

Test Speed : 13 tablet/min

Usage : Pharmaceutical laboratories

Application : Measuring tablet crushing strength

Automatic Rockwell Hardness Tester

Control Mode : Automatic digital control

Specimen Size : Height: max 230 mm, Depth: 140 mm

Machine Weight : 120 kg

Test Speed : 50 mm/min

Usage : Rockwell hardness testing of metals and alloys

Application : Metallurgy, laboratory, quality control

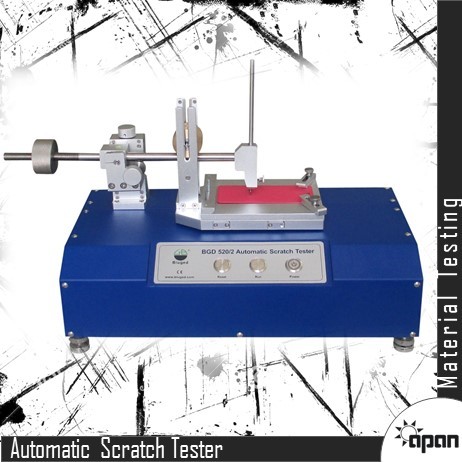

Automatic Scratch Tester

Control Mode : Automatic & Manual

Specimen Size : 100 50 mm (max)

Machine Weight : Approx. 30 kg

Test Speed : 10200 mm/min (adjustable)

Usage : Laboratory Testing

Application : Scratch Resistance Testing for Coatings, Paints, Platings, Sheets

Portable Hardness Tester

Control Mode : Manual

Specimen Size : 5 mm thickness

Machine Weight : 1.5 kg

Test Speed : Standard, per ASTM E110

Usage : Metal hardness testing

Application : Onsite metal hardness testing

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry