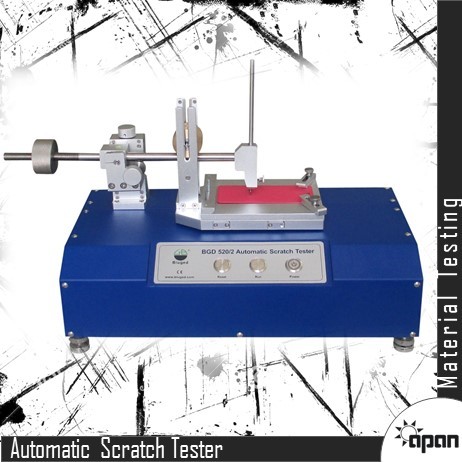

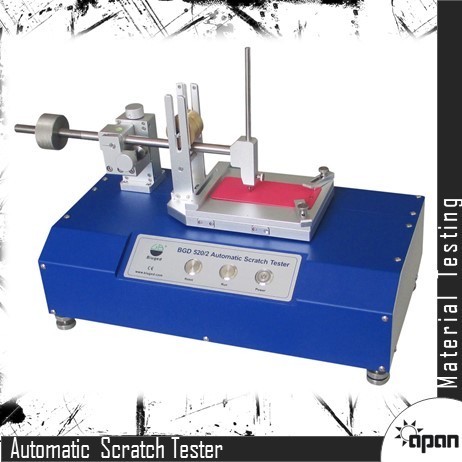

Automatic Scratch Tester

Product Details:

Product Description

As an authorized dealer we are engaged in providing the broad assortment of Material Testing Equipment for various applicants.

Depending on the requirements, there are various methods for testing hardness. Some are dedicated to characterise coatings and others are more suitable for testing bulk materials such as metals, plastics, rubber or elastomers.

Scratch Resistance: To assess a coatings resistance to scratch there are a number of different instruments that can be used: Pencil Hardness Tester (Wolff-Wilborn), Sclerometer, Clemen Apparatus, Scratching and Shearing /Scratch Instrument.

Coatings and paints can protect, decorate substrate or conceal the defects of substrate, and these three functions are related with coatings hardness. And hardness is the important performance for paint mechanical strength, as well as the important indicator to judge paint quality. One of important indicators to evaluate coatings hardness is scratch resistance.

ISO 1518 Paints and varnishes -- Determination of scratch resistance specifies a test method for determining under defined conditions the resistance of a single coating or a multi-coat system of paint, varnish or related product to penetration by scratching with a scratch stylus loaded witha specified load. Penetration of the stylus is to the substrate, except in the case of a multi-coat system, in which case the stylus can penetrate either to the substrate or to an inter mediate coat.

Automatic scratch test principle is to put a single or composite metal test plate fixed on the instrument work platform, when testing, working plat pull test plate at a rate of 30 to 40 mm/s to move slowly, at the same time, loading a load of hemispherical scriber slowly move reverse lines in the coating surface, if the scriber cuts coating, the scriber and test plate will show conductive between plates. The results are evaluated at a certain load whether the needle cuts through coating or a needle does not cut through of maximum load.

This test has been found to be useful in comparing the scratch resistance of different coatings. It is most useful in providing relative ratings for a series of coated panels exhibiting significant differences in scratch resistance.

- Big working table can be moved left and right convenient for measuring different areas in the same panel

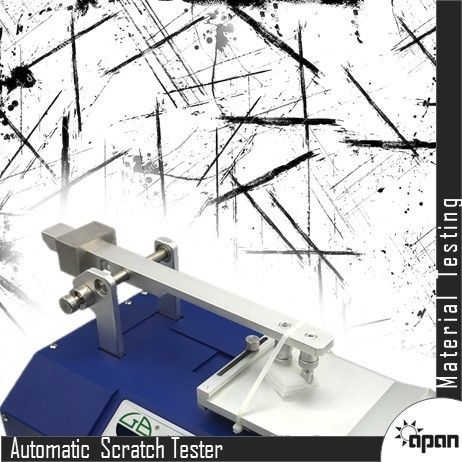

- Special fixing device for sample---can test different size substrate

- Sound-light Alarm system for puncturing through sample panel---more visual

- High hardness material stylus--more durable

Specification

| Advance Model | Basic Model |

Conform standards | ISO 1518-1 BS 3900E2 | ISO 1518-2 |

Stylus | Having a hemispherical hard-metal tip of radius 0.25mm or 0.5mm Having a hemispherical synthetic-ruby of radius 0.25mm or 0.5mm | Coned sapphire or diamond, the tip radius is 0.03mm |

Angle between stylus and sample | 90 | 90 |

Weight | Constant-loading (0.5N1pc1N1pc2N2pcs5N1pc10N1pc | Variable-loading0g50g or 0g100g or 0g200g |

Motor | 60W 220V 50HZ | |

Sytlus Moving Speed | (355mm/s | 102mm/s |

Working Distance | 120mm | 100mm |

Max. Panel Size | 200mm100mm | |

Max. Panle Thickness | Less than 1mm | Less than 12mm |

Overall Size | 500260380mm | 500260340mm |

Net Weight | 17 KG | 17.5KG |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Material Testing' category

|

APAN ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry