Barcol Impressor Hardness Tester

Barcol Impressor Hardness Tester Specification

- Specimen Size

- Minimum thickness 1.3 mm

- Equipment Type

- Portable Hardness Tester

- Temperature

- 0C - 40C (operating range)

- Accuracy

- 1 Barcol unit

- Test Range

- Barcol 0-100 units

- Humidity

- 85% RH (operating range)

- Features

- Lightweight, Portable, Easy to use

- Response Time

- Instantaneous

- Hardness

- Reads Barcol Hardness Value

- Application

- Hardness testing of aluminium, aluminium alloys, FRP, plastics and soft metals

- Display Type

- Analog Dial

- Interface Type

- None (mechanical measurement)

- Power Supply

- Not required (mechanical)

- Mounting Type

- Handheld

- Measuring Range

- Barcol 0-100 units

- Automation Grade

- Manual

- Resolution

- 1 Barcol unit

- Number of Specimens

- Single specimen per test

- Usage

- On-site and laboratory material hardness analysis

- Machine Weight

- 0.5 kg

- Test Speed

- Manual operation

- Control Mode

- Manual

- Operating Principle

- Penetration resistance measurement

- Calibration

- Adjustable, with included test blocks

- Included Accessories

- Carrying case, calibration test blocks, adjusting screwdriver

- Indenter Type

- Flat tip, hardened steel

- Model Compatibility

- GYZJ-934-1 (Barcol Type)

- Dimensions

- 150 mm × 55 mm × 25 mm

- Body Material

- Aluminum alloy housing

Barcol Impressor Hardness Tester Trade Information

- Main Export Market(s)

- Asia

About Barcol Impressor Hardness Tester

As a Authorized dealer we are engaged in providing the broad assortment of "Hardness Testers".

These easy to use hardness testers are ideal for testing the hardness of soft metals, plastics, fibreglass and leather.

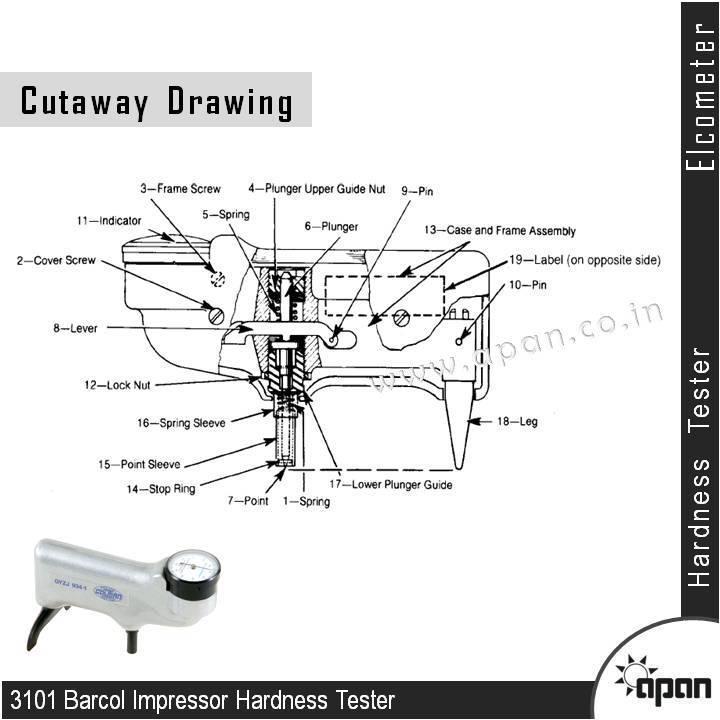

Making sure the indenter point is perpendicular to the surface being tested, the instrument is placed onto the sample and a light pressure is exerted against the instrument driving the spring-loaded indenter point into the material and the hardness reading is instantly indicated on the dial. No waiting, pre-loading or separate measurements are required.

There are three models in the range:

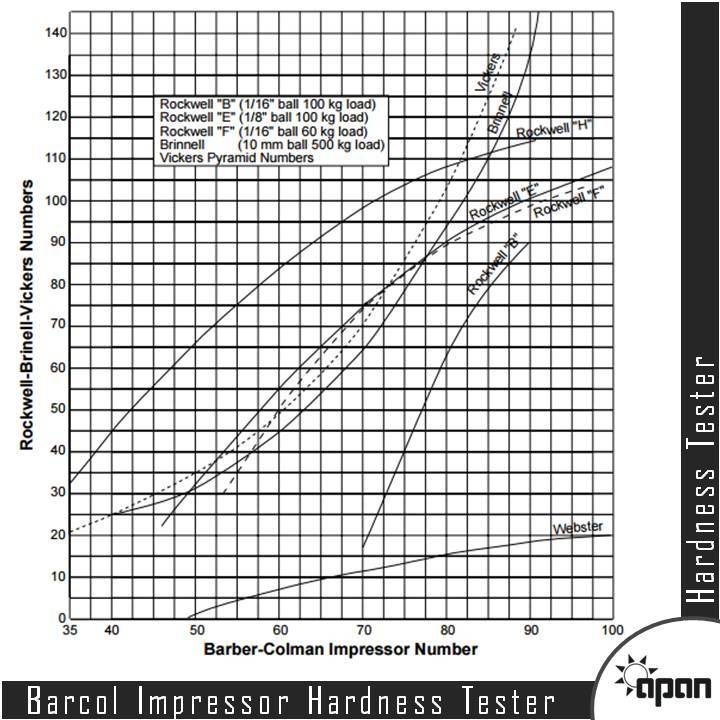

- 934-1 for soft metals such as aluminum and its alloys, brass, copper, and some of the harder plastics and fiberglass. Approximate range 25 to 150 Brinell (10 mm ball 500 kg load). This unit meets American Society for Testing and Materials (ASTM) Standard D2583.

- 934-1-0-1 a variation of the 934-1 that has a "flat bottom" shaped support leg. This is used to sit on top of the crest of the round rung of a ladder such as a fire department ladder. Approved by the NFPA, National Fire Protection Agency.

- 935 for the softer plastics and very soft metals.

- 936 for extremely soft materials such as lead, linoleum and leather.

To ensure the Barcol Hardness Tester is in calibration, a range of Standard Test Discs is available. Please select the appropriate Test Disc from the list of Accessories to supplement the disc supplied.

All results are recorded in Barcol Units (BU).

Barcol Impressor is mainly put to test aluminum and aluminum alloys. Webster is used to test aluminum alloy extrusions, sheet and tubings. Barcol Impressor is suitable to test pure aluminum, soft aluminum alloys, super thick aluminum alloys, aluminum alloys bars and assembled aluminum alloys parts (e.g. al-alloy door &window, scaling ladder etc.)

Barcol Impressor is also used to test fiber reinforced plastics and rigid plastics etc.

Relevant Standard: ASTM B648 (Test Method for Indentation Hardness of Aluminum Alloys by Means of a Barcol Impressor)

Versatile Hardness Testing for Multiple Materials

This Barcol Impressor offers reliable hardness evaluation across aluminum, aluminum alloys, fiber-reinforced plastics (FRP), various soft metals, and plastics. Its robust construction and easy calibration make it suitable for a variety of industrial and quality control applications, ensuring dependable results each time.

Designed for Portability and Durability

Built with an aluminum alloy housing and weighing just 0.5 kg, this handheld tester comes with a carrying case for safe, simple transport. Its mechanical operation and analog dial enable use in locations without power, making it an excellent choice for both fieldwork and laboratory analysis.

Simple Manual Operation and Fast Results

The manual control mode ensures anyone can use the device with ease, requiring no special training. The penetration resistance principle, instant display, and adjustable calibration allow users to quickly verify material hardness, optimizing workflow without compromising precision.

FAQs of Barcol Impressor Hardness Tester:

Q: How does the Barcol Impressor Hardness Tester measure hardness?

A: The Barcol Impressor operates on the principle of penetration resistance, utilizing a hardened steel, flat-tip indenter to press into the specimens surface. The depth of penetration is immediately translated into a Barcol hardness value, displayed on an analog dial.Q: What materials are suitable for testing with this device?

A: This hardness tester is ideal for checking the hardness of aluminum, aluminum alloys, fiber-reinforced plastics (FRP), various plastics, and other soft metals. It requires specimens with a minimum thickness of 1.3 mm for accurate measurement.Q: When is calibration required and how is it performed?

A: Calibration is recommended before initial use and periodically during regular operation to maintain accuracy. The instrument comes with test blocks and an adjusting screwdriver for straightforward, manual calibration following the included instructions.Q: Where can I use this tester effectively?

A: The devices portability and mechanical operation make it suitable for both laboratory environments and on-site inspections. Its operational temperature range (0C - 40C) and humidity tolerance (up to 85% RH) support varied industrial settings.Q: What is the measurement process for a single specimen?

A: Place the tester on a flat, clean specimen at least 1.3 mm thick. Press the device steadily until the indenter penetrates and the dial displays a reading. One specimen is tested per measurement, with instant results shown on the analog display.Q: What are the main benefits of using this Barcol Impressor model?

A: Key benefits include its lightweight, portable form factor, mechanical operation (no power needed), and fast, easy-to-read results. The testers robust design and included accessories make it a reliable tool for distributors, importers, and industrial quality control professionals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Vickers Hardness Measuring System

Accuracy : 1%

Equipment Type : Hardness Measuring System

Specimen Size : Maximum Height 70 mm

Hardness : Vickers (HV)

Response Time : Instantaneous

Features : Automatic measuring, data storage, precise measurement

Manual Digital Rockwell Hardness Tester

Accuracy : 1%

Equipment Type : Manual Digital Rockwell Hardness Tester

Specimen Size : Height 170 mm, Depth 135 mm

Hardness : Rockwell C (HRC) scale

Response Time : Instantaneous

Features : High precision, easy operation, digital readout

Digital RockwellHardness Tester

Accuracy : 1 HRC

Equipment Type : Digital Rockwell Hardness Tester

Specimen Size : 2 mm to 60 mm

Hardness : HRC, HRB, HRA

Response Time : Instantaneous digital reading

Features : Direct digital reading, memory function, automatic/manual operation modes

Magnetic Rockwell Hardness Tester

Accuracy : 1 HRC

Equipment Type : Magnetic Rockwell Hardness Tester

Specimen Size : Up to 55 mm (diameter)

Hardness : Rockwell C (HRC) Scale

Response Time : Immediate

Features : Portable, Magnetic base, Easy to operate

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry