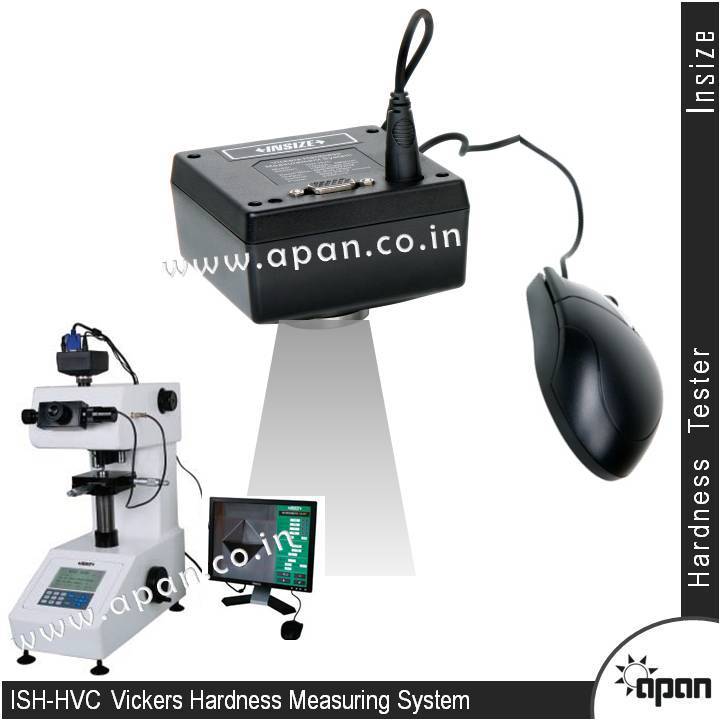

Vickers Hardness Measuring System

Vickers Hardness Measuring System Specification

- Operating Voltage

- 220V AC

- Test Range

- 5HV~3000HV

- Features

- Automatic measuring, data storage, precise measurement

- Power Supply

- AC 220V 10%, 50Hz

- Interface Type

- USB/RS232

- Automation Grade

- Semi-Automatic

- Hardness

- Vickers (HV)

- Display Type

- Digital LCD Display

- Accuracy

- 1%

- Temperature

- 10C 35C

- Frequency

- 50 Hz

- Number of Specimens

- Single Specimen

- Response Time

- Instantaneous

- Equipment Type

- Hardness Measuring System

- Port Size

- Standard

- Max Height

- 70 mm

- Resolution

- 0.01 HV

- Specimen Size

- Maximum Height 70 mm

- Humidity

- 85% RH

- Measuring Range

- 5HV3000HV

- Mounting Type

- Benchtop

- Application

- Material Hardness Testing

- Usage

- Metallurgical, Research Labs, Industrial Testing

- Capacity

- No specific limit

- Machine Weight

- 60 kg

- Test Speed

- Adjustable

- Test Width

- Up to 100 mm

- Test Stroke

- Adjustable stroke

- Control Mode

- Digital/Automatic

Vickers Hardness Measuring System Trade Information

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

About Vickers Hardness Measuring System

Our clients widely trust us as the topmost company, engaged in supplying an excellent quality Vickers Hardness Measuring System. Installed with the latest optical system, this is manufactured using high grade materials in complete compliance with industry standards. Vickers Hardness Measuring System is used for measuring the dimensions of indentation image.

Features:

- Extended service life

- Robust design

- High energy efficiency

High Precision Optical System

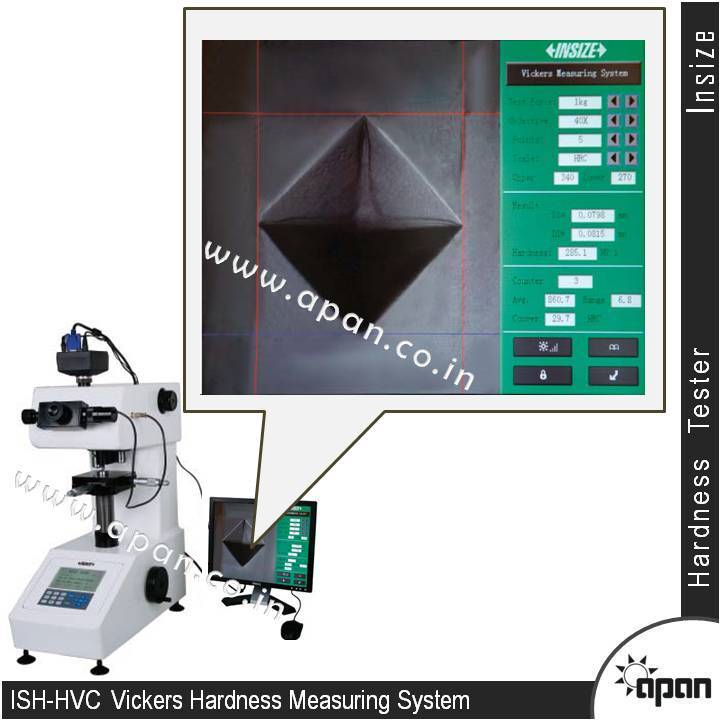

Equipped with a sophisticated optical setup, the system achieves 400x magnification, enabling clear and accurate measurement of micro-indents. The LED illumination ensures optimal visibility and stability during testing, even under challenging laboratory conditions. This advanced optical system helps maintain accuracy and consistency in hardness testing.

Reliable Measurement & Data Handling

Employing both automatic optical and manual measurement methods, this system offers flexibility in operation. The integrated analysis software supports instant data interpretation, storage of up to 1000 results, and direct output via USB and printer interfaces, simplifying data management for labs and industrial users.

Versatile Testing Capabilities

Designed for a wide range of materials, the Vickers Hardness System supports a test range from 5HV to 3000HV. The adjustable test speed, stroke, and width accommodate various specimen sizes up to 70 mm high, making it ideal for metallurgical research and industrial environments requiring rigorous hardness evaluation.

FAQs of Vickers Hardness Measuring System:

Q: How does the Vickers Hardness Measuring System ensure high accuracy in readings?

A: This system uses a precision optical system with LED illumination and a Vickers diamond indenter. The automatic and manual measuring methods, combined with digital analysis software, deliver highly accurate results with a resolution of 0.01 HV and an accuracy of 1%.Q: What is the process for conducting a hardness test using this equipment?

A: To test material hardness, place the specimen on the benchtop mount, adjust the load (from 10g to 1kg) and stroke as needed, and initiate testing through the digital interface. The automated optical system measures the indent and instantly displays results on the digital LCD.Q: When should this system be used for material testing?

A: Its ideal for metallurgical labs, industrial research, and quality control departments needing precise Vickers hardness measurement for single specimens up to 70 mm in height, especially within a testing range of 5HV to 3000HV.Q: Where can the Vickers Hardness Measuring System be installed?

A: This benchtop instrument is best suited for vibration-free, dust-controlled laboratory environments with humidity 85% RH and temperatures between 10C and 35C. It operates on standard Indian voltage (220V AC, 50 Hz).Q: What are the data storage and output options available on this system?

A: The system can store up to 1000 test results in its memory and supports data output via USB interface and printer. The analysis software also aids in processing and exporting data for further usage.Q: How does using this system benefit research and quality assurance activities?

A: It offers precise, repeatable hardness measurements with efficient digital control, immediate response time, and comprehensive data handling. These features accelerate material evaluation, improve reliability, and streamline internal documentation and reporting in research and industrial settings.Q: Is there any limit on specimen capacity or size for testing?

A: The system can handle single specimens with a maximum height of 70 mm and a test width up to 100 mm, accommodating most standard samples used in material science and industrial testing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Digital Compression Testing Machine

Usage : Material Testing

Automation Grade : Automatic

Features : Auto peak hold, Overload protection, Realtime data output

Control Mode : Digital, Automatic

Accuracy : 1% of displayed value

Hardness : Heavy Duty Cast Iron

Pin Brinell Hardness Tester

Usage : Metallurgy, Automotive, Manufacturing

Automation Grade : Manual

Features : Portable, Robust Construction, Easy Calibration

Control Mode : Manual

Accuracy : 1%

Hardness : Up to 650 HB

Elcometer Shore Durometer

Usage : Hardness testing of nonmetallic materials

Automation Grade : Manual

Features : Portable, analog dial, easy to operate

Control Mode : Analog

Accuracy : 1 Shore unit

Hardness : 0 to 100 Shore A (or D)

Barcol Impressor Hardness Tester

Usage : Onsite and laboratory material hardness analysis

Automation Grade : Manual

Features : Lightweight, Portable, Easy to use

Control Mode : Manual

Accuracy : 1 Barcol unit

Hardness : Reads Barcol Hardness Value

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry