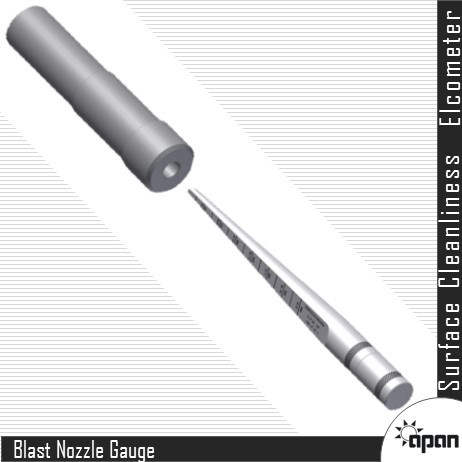

Blast Nozzle Gauge

Blast Nozzle Gauge Specification

- Application

- Measuring blast nozzle interior diameter and wear

- Features

- Portable, easy to operate, corrosion-resistant

- Mounting Type

- Handheld

- Humidity

- 0-90% RH (Non-condensing)

- Response Time

- Instantaneous

- Resolution

- 0.1 mm

- Automation Grade

- Manual

- Max Height

- 180 mm

- Measuring Range

- 5 mm 25 mm

- Temperature

- -10C to 50C

- Equipment Type

- Blast Nozzle Gauge

- Accuracy

- 0.1 mm

- Display Type

- Analog (Dial Gauge)

- Usage

- Industrial, maintenance, calibration

- Machine Weight

- 210g

- Control Mode

- Manual

Blast Nozzle Gauge Trade Information

- Main Export Market(s)

- Asia

About Blast Nozzle Gauge

The Elcometer 103 Blast Nozzle Gauge is a simple tool designed to give a quick and easy measurement of the orifice size of an abrasive blasting nozzle. Proper use of this gauge can determine nozzle orifice wear which can cause low nozzle pressure and decreased efficiency in the performance of the nozzle's venturi.

This wear results in decreased productivity, increased abrasive consumption and improper surface profile.

Product details

| Dimensions | 200 x 19mm (7.87 x 0.75") |

| Model Name/Number | Elcometer 103 |

| Weight | 150g (5.29oz) |

| Purpose | measures the orifice size of an abrasive blasting nozzle. |

| Measuring Range | 6.4 - 16mm, 1/4 - 5/8" (81-548CFM) |

| Inside gauge | wax/grease pencil |

Precision Measurement for Industrial Applications

Engineered for industrial environments, this Blast Nozzle Gauge provides reliable measurement of nozzle interior diameter and wear. Its durable stainless steel and aluminum construction ensures longevity and consistent accuracy, making it essential for calibration and maintenance teams operating in abrasive, high-impact settings.

Designed for Harsh and Abrasive Settings

Powder-coated for superior corrosion resistance, the gauge withstands tough operating conditions. The knurled handle offers a firm grip even when used with gloves, ensuring safe and precise manual operation. Supplied with a protective carrying case, its suitable for demanding field work across the humidity and temperature range specified.

Instantaneous Analog Display and Laser-Etched Scale

The analog dial gauge provides instant feedback for fast and accurate readings, boasting resolution down to 0.1 mm. Laser-etched scale markings remain clear and easy to read over years of use, while manual control guarantees user-oriented operation without the need for batteries or calibration downtime.

FAQs of Blast Nozzle Gauge:

Q: How do I use the Blast Nozzle Gauge to measure internal diameters?

A: To use the gauge, insert the measuring tip gently into the nozzles interior and manually turn the dial until it contacts the surface. The analog dial instantly displays the internal diameter, with clear laser-etched markings for effortless precision.Q: What are the main benefits of using this gauge in abrasive environments?

A: Thanks to its stainless steel and aluminum build and powder-coated finish, the gauge offers excellent resistance to abrasion and corrosion. This ensures accuracy and longevity, even when used in challenging industrial conditions.Q: When should I check blast nozzles for wear with this gauge?

A: Routine inspections should be performed before and after each blast operation or during scheduled maintenance intervals. Monitoring wear helps maintain optimal performance and reduces downtime associated with nozzle degradation.Q: Where is this Blast Nozzle Gauge best utilized?

A: The gauge is ideally suited for industrial, maintenance, and calibration settings, particularly in abrasive blasting operations. Its portability and robust design make it valuable in both field and workshop environments.Q: What is the process for cleaning and storing the gauge?

A: After use, wipe the gauge with a clean, dry cloth to remove residue. Store it in its protective carrying case to shield it from dust, moisture, and potential impact, ensuring longevity and measurement reliability.Q: Can this gauge measure different sizes of blast nozzles?

A: Yes, it is designed to measure nozzle internal diameters from 5 mm to 25 mm, making it suitable for a wide range of nozzle sizes used in industrial blasting.Q: What advantages does the analog dial and laser-etched markings offer?

A: The analog dial enables immediate measurement display without power requirements, while the laser-etched markings ensure enduring readability and facilitate precise, repeatable measurements over extended use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Inspection Category

Banana Gauge

Test Range : 0 200 mm

Mounting Type : Benchtop

Features : Portable, robust, easy operation

Application : Banana shape measurement, straightness gauge for fruit

Temperature : 10C to 40C

Automation Grade : Semiautomatic

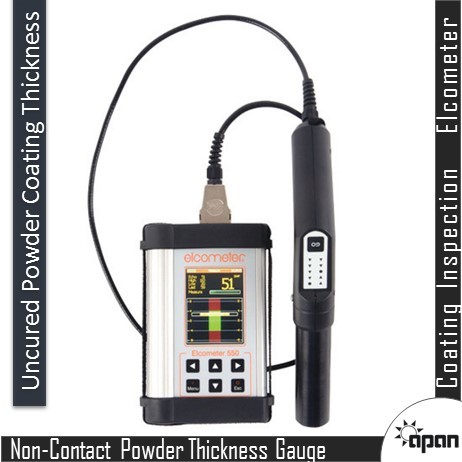

Non-Contact Powder Thickness Gauge

Test Range : 0~5 mm

Mounting Type : Tabletop

Features : Noncontact measurement, high accuracy, digital display, fast response

Application : Powder thickness measurement

Temperature : 5C~35C

Automation Grade : Automatic

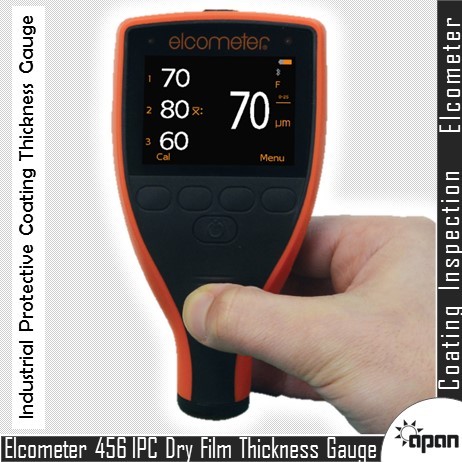

Ferrous Metal Coating Thickness Gauge

Test Range : 0 to 1250 m

Mounting Type : Handheld

Features : Auto shut off, Low battery indicator, Portable design

Application : Measurement of coating thickness on ferrous substrates

Temperature : 0C to 50C

Automation Grade : Manual

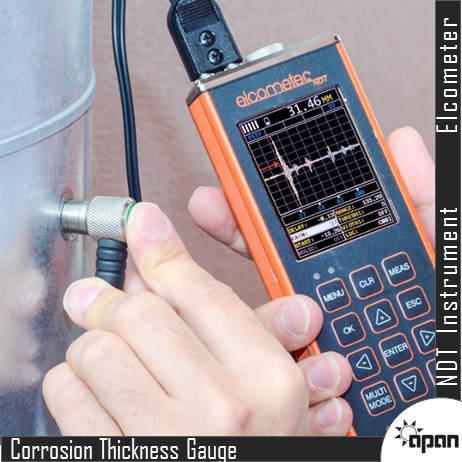

Corrosion Thickness Gauge

Test Range : 1.2 to 225.0 mm (in steel)

Mounting Type : Handheld

Features : Low battery indication, automatic shutdown, metric/imperial selectable, data hold

Application : Corrosion measurement, thickness testing of metals and other solid materials

Temperature : 10C to 60C

Automation Grade : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry