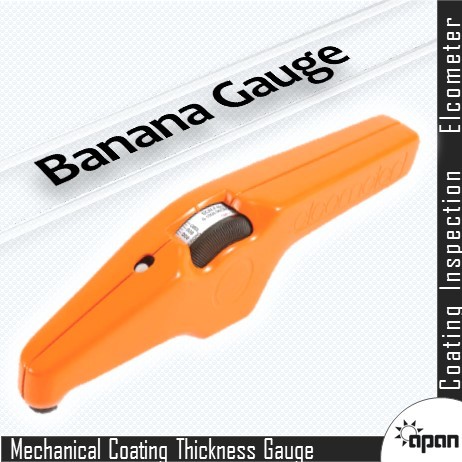

Banana Gauge

Banana Gauge Specification

- Frequency

- 50 Hz

- Operating Voltage

- 220V AC

- Test Range

- 0 - 200 mm

- Max Height

- 300 mm

- Temperature

- 10C to 40C

- Port Size

- 1/4 BSP

- Response Time

- Immediate (<1 sec)

- Equipment Type

- Banana Gauge

- Power Supply

- AC 220V, 50 Hz

- Application

- Banana shape measurement, straightness gauge for fruit

- Features

- Portable, robust, easy operation

- Automation Grade

- Semi-automatic

- Number of Specimens

- 1

- Resolution

- 0.01 mm

- Gas Pressure

- 6-8 bar

- Accuracy

- 0.05 mm

- Interface Type

- USB/Data port optional

- Measuring Range

- 0-200 mm

- Specimen Size

- Up to 150 mm length

- Hardness

- Instrument body: 60 HRC

- Display Type

- Digital & Analog (dual display)

- Mounting Type

- Bench-top

- Humidity

- 20% - 80% RH (non-condensing)

- Usage

- Quality control, shape analysis in agriculture

- Capacity

- Up to 40 kg

- Machine Weight

- Approx. 35 kg

- Test Speed

- Adjustable up to 200 mm/min

- Test Width

- 100 mm

- Test Stroke

- 200 mm max

- Control Mode

- Manual or Automatic

- Calibration

- Factory calibrated with calibration certificate

- User Interface

- Simple keypad control

- Material

- Stainless steel measurement jaws, powder-coated body

- Display Unit

- LCD backlit

- Protection Class

- IP20

- Compliance

- ISO 9001 Certified

- Movable Parts

- Precision ball bearing slides

- Data Storage

- Up to 1000 test results

- Ambient Light Operating Range

- 0-5,000 lux

Banana Gauge Trade Information

- Payment Terms

- Cash in Advance (CID)

About Banana Gauge

The Elcometer 211 Coating Thickness Gauge measures non-magnetic coatings, including paint, hard chrome, electroplating, galvanising, powder coating, plastic, epoxy and rubber applied to a ferromagnetic base.

The traditional type banana gauge offered a display of the measurement in analog format which always required a certain amount of interpretation from the user, as this instrument has a digital indication this interpretation is no longer required turning the gauge into a very powerful measurement tool.

How to Measure Coating Thickness :

- Place the end and middle of gauge on test surface. Rotate the thumb wheel forward until the magnet makes contact with the surface and the indication on the scale is above the estimated coating thickness, otherwise to maximum.

- Rotate the thumbwheel back until magnet is released from surface, the indicator pops up and click is heard.

- Stop turning immediately. Repeat to confirm the reading.

- Lift the gauge and read the thickness value on the scale in line with the pointer.

This is one of the most popular mechanical coating thickness gauges in the world.

- Factory calibrated - with user calibration adjustment

- Foils supplied to check calibration on site

- Ideal for cold surfaces and underwater use

- Small and portable with an accuracy ±5%

- The V grooved base, ideal for pipeline inspection

PRODUCT RANGE :

- Elcometer 211 Coating Thickness Gauge / Banana Gauge : 0 - 1000µm

- Elcometer 211 Coating Thickness Gauge / Banana Gauge : 0.65 - 6mm

- Elcometer 211 Coating Thickness Gauge / Banana Gauge : 0 - 40mils

- Elcometer 211 Coating Thickness Gauge / Banana Gauge : 25 - 250mils

Specification

| Edge Effects | Must be at least 6mm (0.24") from edge |

| Brand | Elcometer |

| Measuring Range | 0 - 6000 micron |

| Accuracy | +-5% of the reading or +-2.5 micron 0.1mil |

| Display | Analog |

| Display Type | Metric or Imperial |

| Type | Mechanical Coating Thickness Gauge |

| Model Name/Number | Elcometer 211 Banana Gauge |

| Length | 200 x 60 x 30mm (7.8 x 2.4 x 1.2") |

| Substrate Thickness | 0.4mm (16mils) minimum |

| STANDARDS: | AS 2331.1.3, AS 3894.3-A, ASTM G 12, ASTM B 499, AS/NZS 1580.108.1, BS 5411-11, BS 3900-C5-6A |

| Measurement Area | 30mm (1.18") Diameter minimum |

Superior Measurement Precision

Equipped with stainless steel jaws and precision slides, the Banana Gauge delivers reliable and repeatable measurements. Its wide measuring range and high accuracy provide valuable data for banana shape and straightness analysis in agricultural operations.

Robust Construction for Agricultural Demands

With a powder-coated enclosure and a body hardness of 60 HRC, the instrument is designed to withstand rigorous use. The IP20 protection class and bench-top mounting ensure it stays resilient even under frequent laboratory or field conditions.

Intuitive Operation and Data Management

The gauge features a simple keypad for control and a backlit LCD for clear visibility. It accommodates up to 1000 test results with optional USB/data port connectivity, supporting efficient workflow and recordkeeping for quality assurance teams.

FAQs of Banana Gauge:

Q: How does the Banana Gauge measure the shape and straightness of bananas?

A: The Banana Gauge uses precision ball bearing slides and stainless steel measurement jaws to detect the contours and straightness of a banana specimen. Test strokes up to 200 mm allow comprehensive measurement, while its dual display system shows results instantly.Q: What is the process for calibrating and using the device?

A: The Banana Gauge is factory calibrated, and each unit ships with a calibration certificate. For operation, simply place the banana specimen on the instrument, set the test parameters using the keypad, and initiate the test in either manual or automatic mode. Results are displayed instantly and can be stored for later analysis.Q: When should the Banana Gauge be used in agricultural quality control?

A: This equipment is ideal for use during post-harvest quality assessments, research on banana shape conformity, or during breeding trials to analyze fruit development. It ensures accuracy and repeatability for consistent reporting.Q: Where can the Banana Gauge be installed and operated?

A: Designed for bench-top mounting, the device is suitable for laboratories, quality assurance facilities, and research centers. The operating environment should have a temperature range of 10C40C, humidity of 20%80% RH, and ambient light up to 5,000 lux.Q: What are the benefits of using this gauge for banana quality analysis?

A: Benefits include precise and immediate shape analysis, robust construction for frequent use, large data storage for research or recordkeeping, compliance with ISO standards, and support for both manual and automated measurementall contributing to improved product consistency and quality.Q: How is data managed and exported from the instrument?

A: Test results are stored in the built-in memory, supporting up to 1000 entries. For data export, an optional USB/data port allows easy transfer to external devices, streamlining documentation and further analysis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Inspection Category

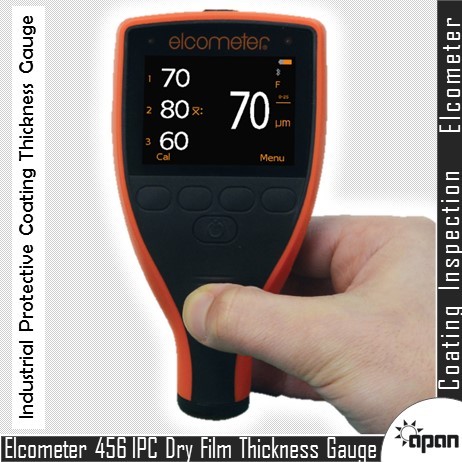

Ferrous Metal Coating Thickness Gauge

Application : Measurement of coating thickness on ferrous substrates

Usage : Surface coating thickness measurement

Features : Auto shut off, Low battery indicator, Portable design

Mounting Type : Handheld

Equipment Type : Ferrous Metal Coating Thickness Gauge

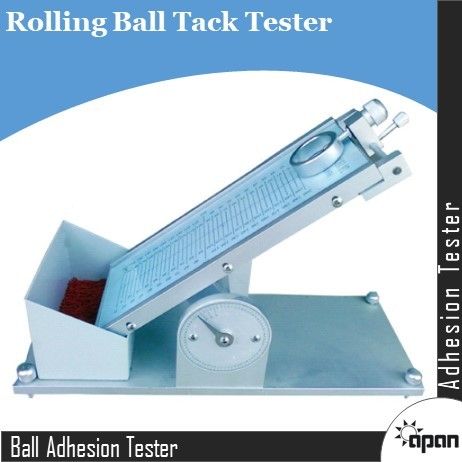

Ball Adhesion Tester

Application : Adhesive tape and label adhesion testing

Usage : Ball tack/Adhesion testing

Features : Portable, easy to use, sturdy construction

Mounting Type : Benchtop

Equipment Type : Adhesion Tester

Cross Hatch Adhesion Test Tape

Minimum Order Quantity : 1 Piece

Application : Coating Adhesion Test, Paints, Plastics, Metal Finishes

Usage : Industrial

Features : High Tack Adhesive, Clean Removal, Consistent Thickness

Mounting Type : Handheld/Manual

Equipment Type : Adhesion Test Tape

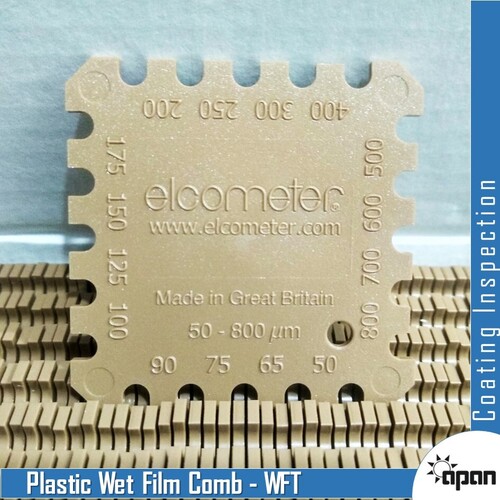

Plastic Wet Film Combs

Minimum Order Quantity : 1 Kit

Application : Measuring wet film thickness of paints, coatings and similar materials

Usage : Industrial, laboratory, field

Features : Corrosion resistant, lightweight, easy to use, nonreactive

Mounting Type : Handheld

Equipment Type : Plastic Wet Film Comb

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry