Elcometer 456 Coating Thickness Gage Probe

Elcometer 456 Coating Thickness Gage Probe Specification

- Interface Type

- USB/RS232 (model dependent)

- Resolution

- 0.1 m (0.004 mil)

- Response Time

- < 1 second

- Measuring Range

- 0 to 1500 m (0 to 60 mils)

- Temperature

- Operating: -10C to 50C (14F to 122F)

- Mounting Type

- Handheld

- Accuracy

- 1 to 3% of reading (+1 m)

- Equipment Type

- Coating Thickness Gauge Probe

- Humidity

- Up to 95% RH (non-condensing)

- Number of Specimens

- Single Point or Continuous Mode

- Automation Grade

- Manual

- Specimen Size

- Minimum Diameter: 5 mm, Minimum Thickness: 0.3 mm

- Features

- Menu-driven interface, user calibration, data logging, three calibration methods, date and time stamp, measurement statistics

- Display Type

- Large, illuminated LCD digital display

- Test Range

- 0 to 1500 m (0 to 60 mils) depending on probe model

- Application

- Measuring coating thickness on ferrous & non-ferrous substrates

- Power Supply

- 2 x AA dry cells (1.5 V each)

- Operating Voltage

- 3V (2 x 1.5V AA batteries)

- Usage

- For industrial, automotive, and laboratory coating thickness measurement

- Capacity

- Stores up to 1500 readings (internal memory)

- Machine Weight

- 110 g (including probe and batteries)

- Test Speed

- Up to 70 readings/minute

- Control Mode

- Manual

- Battery Life

- Up to 24 hours continuous use

- Data Output

- Compatible with ElcoMaster Data Management Software

- Dimensions

- 141 x 73 x 37 mm (gage unit)

- Probe Type

- Interchangeable, integral and remote probes available (ferrous, non-ferrous, dual) depending on model

- Protection

- IP64 (probe), dust and splash proof

- Substrate Types

- Ferrous (F) and Non-ferrous (N) metals

- Calibration Method

- Zero, smooth, and rough substrate calibration options

About Elcometer 456 Coating Thickness Gage Probe

As a Authorized dealer we are engaged in providing the broad assortment of Elcometer, UK make Dry Film Coating Thickness (DFT) gauge used to measure the thickness of dry film coating, this gauge is well known in worldwide.

All Elcometer 456 probes are fully interchangeable and are available in a number of designs and scale ranges to meet your specific application.

Ferrous probes measure non magnetic coatings on ferro-magnetic substrates. Elcometer 456 ferrous gauges accept any ferrous probe. Non-ferrous probes measure non conductive coatings on non-ferrous metal substrates and Elcometer 456 non-ferrous gauges accept any non-ferrous probe. Dual FNF probes measure both ferrous and non-ferrous applications with automatic substrate detection. Elcometer 456 FNF gauges accept all ferrous, non-ferrous and dual FNF probes.

Unless stated, Elcometer separate probes have a maximum operating temperature of 150F), PINIP probes have a maximum operating temperature of 80C (176 F).

Every Elcometer 456 gauge and separate probe is supplied with a Test Certificate free of charge. For separate gauges, the test measurements are generated using factory reference probes.

Feature

- All Elcometer 456 probes are fully interchangeable and are available in a number of designs and scale ranges to meet your specific application

- Straight Measures coatings on both flat and curved surfaces

- Mini Probes - Ideal for measuring coatings on edges, narrow pipes or small surface areas

- Right Angle Probes For taking readings where access is restricted

- PINIP Probes Plug-in probes convert a separate gauge into an integral gauge

- Telescopic Probes Extending right angle probes for out of reach areas

- Ultra/Scan Probes - These probes are fitted with replaceable probe caps - allowing users to take individual readings or scan large surface areas without damaging the probe

- Waterproof Probes Sealed for use underwater at depth, even in diving gloves

- High Temperature Probes For use on hot coated materials up to 250C (480F)

- Anodiser Probes Chemical resistant washable probes - ideal for the anodising environment

- Armoured Probes Probes with metal reinforced heavy duty cables, reducing the risk of cable damage

- Soft Coating Probes Large surface area probes for soft reach materials (HVCA approved)

- Ferrous probes measure non magnetic coatings on ferro-magnetic substrates. Elcometer 456 ferrous gauges accept any ferrous probe. Non-ferrous probes measure non conductive coatings on non-ferrous metal substrates and Elcometer 456 non-ferrous gauges accept any non-ferrous probe. Dual FNF probes measure both ferrous and non-ferrous applications with automatic substrate detection. Elcometer 456 FNF gauges accept all ferrous, non-ferrous and dual FNF probes.

- Specialist Probes - These probes are designed for measuring on specialist substrates, such as graphite, or electroplated components

Versatile Probe Options

Choose among interchangeable, integral, or remote probes, each tailored for ferrous, non-ferrous, or dual-metal substrate measurements. The flexibility of the Elcometer 456 enables seamless adjustments for a variety of inspection environments, delivering reliable results regardless of specimen type.

Advanced Calibration for Precision

Benefit from zero, smooth, or rough substrate calibration methods, ensuring accurate readings across different surface conditions. This adaptability enhances measurement confidence whether assessing single points or performing continuous scans, supporting critical quality assurance processes.

Efficient Data Management

The Elcometer 456 is equipped with a large, illuminated LCD and can internally store up to 1500 readings. Integration with ElcoMaster Data Management Software enables fast transfer and easy analysis, maximizing productivity on-site or in the lab.

FAQs of Elcometer 456 Coating Thickness Gage Probe:

Q: How do I calibrate the Elcometer 456 Coating Thickness Gage Probe for optimal accuracy?

A: Calibration can be performed using zero, smooth, or rough substrate calibration options. Follow the menu-driven interface to select your preferred method, ensuring you match the calibration to the specific substrate and coating conditions for precise measurement results.Q: What types of substrates and coatings can the Elcometer 456 measure?

A: This gauge is designed for use on both ferrous (F) and non-ferrous (N) metal substrates, making it suitable for a wide range of industrial, automotive, and laboratory applications where accurate coating thickness measurement is required.Q: When should I use the single-point versus continuous measurement modes?

A: Use single-point mode for spot checks or quality control at specific locations. Switch to continuous mode when scanning larger surfaces or when you need a rapid sequence of readings, as the device can capture up to 70 measurements per minute.Q: Where can I access and analyze my stored measurement data?

A: You can conveniently access up to 1500 internally stored readings via the devices USB or RS232 interface (depending on model), and analyze your results using ElcoMaster Data Management Software on your computer for comprehensive data management and reporting.Q: What is the process for changing between the interchangeable, integral, and remote probe types?

A: Switching between probe types is straightforward: simply disconnect the current probe and attach your desired probeinterchangeable, integral, or remote. Ensure the probe is compatible with your measurement needs, whether for ferrous, non-ferrous, or dual-type substrates.Q: What environments can the Elcometer 456 operate in?

A: The Elcometer 456 operates in temperatures from -10C to 50C and tolerates up to 95% relative humidity (non-condensing). With an IP64-rated probe, it is dust and splash proofideal for challenging field or laboratory conditions.Q: What are the main benefits of using the Elcometer 456 Coating Thickness Gage Probe?

A: Key advantages include high measurement accuracy (1 to 3% of reading), fast response time, robust protection for reliability, flexible measurement options, prolonged battery life, large LCD display, and advanced data management capabilities, making it indispensable for quality assurance tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Inspection Category

Cross Hatch Adhesion Test Tape

Minimum Order Quantity : 1 Piece

Mounting Type : Handheld/Manual

Automation Grade : Manual

Usage : Industrial

Features : High Tack Adhesive, Clean Removal, Consistent Thickness

Application : Coating Adhesion Test, Paints, Plastics, Metal Finishes

Surface Profile Gauge

Mounting Type : Handheld

Automation Grade : Manual

Usage : Surface profile measurement for quality control

Features : Corrosionresistant, easytoread dial, compact design

Application : Measurement of blastcleaned or coated surface profile

Paint Inspection Gauge

Mounting Type : Handheld

Automation Grade : Manual

Usage : Coating thickness inspection

Features : Lightweight, Portable, Precise

Application : Coating and paint thickness measurement

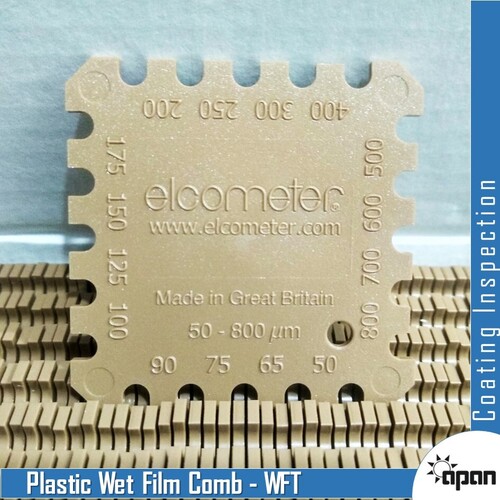

Plastic Wet Film Combs

Minimum Order Quantity : 1 Kit

Mounting Type : Handheld

Automation Grade : Manual

Usage : Industrial, laboratory, field

Features : Corrosion resistant, lightweight, easy to use, nonreactive

Application : Measuring wet film thickness of paints, coatings and similar materials

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry