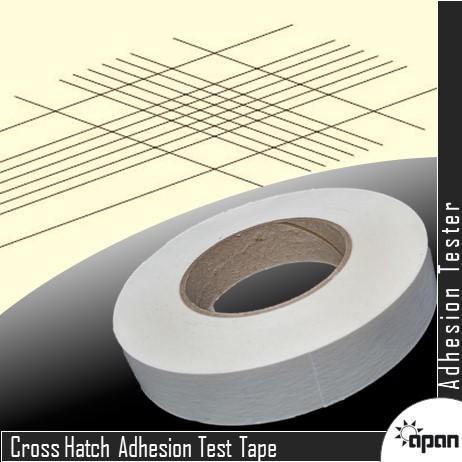

Cross Hatch Adhesion Test Tape

Cross Hatch Adhesion Test Tape Specification

- Product Type

- Cross Hatch Adhesion Test Tape

- Number of Specimens

- Determined by user (typically 3 per test)

- Automation Grade

- Manual

- Equipment Type

- Adhesion Test Tape

- Application

- Coating Adhesion Test, Paints, Plastics, Metal Finishes

- Measuring Range

- Qualitative (per ISO 2409, ASTM D3359 standards)

- Specimen Size

- Minimum 15 mm x 50 mm adhesive area

- Features

- High Tack Adhesive, Clean Removal, Consistent Thickness

- Color

- White

- Humidity

- 0-85% RH (Tape to be stored at ambient humidity)

- Response Time

- Immediate

- Usage

- Industrial

- Temperature

- 10C to 35C (Recommended for testing)

- Interface Type

- Manual

- Test Range

- Visual assessment (0-5 rating scale as per standard)

- Accuracy

- Subjective (assessment as per test method)

- Mounting Type

- Handheld/Manual

- Capacity

- Single roll

- Test Speed

- Manual application

- Test Width

- 24 mm (typical, can vary by manufacturer)

- Control Mode

- Manual

Cross Hatch Adhesion Test Tape Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Cross Hatch Adhesion Test Tape

As a Authorized dealer we are engaged in providing the broad assortment of Coating Inspection Equipments.

A crosshatch pattern is made through the film to the substrate. Detached flakes of coating are removed by brushing with a soft brush. Pressure-sensitive tape is put over the crosshatch cut. Tape is smoothed into place by using a pencil eraser over the area of the incisions. Tape is removed by pulling it off rapidly back over itself. Adhesion is assessed on a 0 to 5 scale. [0- Greater than 65% area removed & 5 is 0% area removed]

It is designed as a replacement for Permacel P-99 tape. It will be use with used in conjunction

with ASTM D 3359: Standard Test Methods for Measuring Adhesion by Tape Test.

FEATURES AND BENEFITS

- Excellent quick-stick and high-hold characteristics

- oisture and abrasion resistant

- It will not conceal surface cross hatch test patterns when burnished

- A

- dhesive will not delaminate from the backing material when the tape is removed from a surface.

- Adhesion tape compliance to ISO 2409 is also available.

Specification

|

Description |

Cutter Type |

Coating Thickness |

Certificate |

|

|

Elcometer 1542 Basic Kit |

6 x 1mm |

0 - 60m |

0 - 2.4mils |

0 |

|

Elcometer 1542 Basic Kit |

6 x 2mm |

50 -125m |

2 - 5.0mils |

0 |

|

Elcometer 1542 Basic Kit |

6 x 3mm |

121 -250m |

4.8 - 9.8mils |

0 |

|

Elcometer 1542 Full Kit - ISO Tape |

6 x 1mm |

0 -60m |

0 - 2.0mils |

0 |

|

Elcometer 1542 Full Kit - ISO Tape |

6 x 2mm |

50-125m |

0 - 2.0mils |

0 |

|

Elcometer 1542 Full Kit - ISO Tape |

6 x 3mm |

121 -250m |

4.8 - 9.8mils |

0 |

|

Elcometer 1542 Full Kit - ASTM Tape |

6 x 1mm |

0-60m |

0 - 2.4mils |

0 |

|

Elcometer 1542 Full Kit - ASTM Tape |

6 x 2mm |

50 - 125m |

2 - 5.0mils |

0 |

|

Elcometer 1542 Advanced Kit - ISO Tape |

6 x 1 2 3mm |

0 - 250m |

0 - 9.8mils |

0 |

|

Elcometer 1542 Advanced Kit -ASTM Tape |

6 x 1 2 3mm |

0 - 250m |

0 - 9.8mils |

0 |

Industry-Leading Adhesion Testing Tape

This test tape is engineered for reliable coating adhesion assessments in various industries, including paints, plastics, and metal finishes. Its pressure sensitive adhesive and PET film backing provide consistent performance during manual testing. With a measuring range tailored to qualitative evaluation standards and a robust design, it ensures accuracy and repeatability for manufacturers, suppliers, and laboratories.

Simple Visual Assessment Process

Using the tape is straightforwardapply manually to the substrate, create cross-hatch cuts per standard protocol, and evaluate the adhesion by visually inspecting the removal pattern. Results are assessed on a 0-5 scale, as specified by ISO 2409 and ASTM D3359, delivering immediate feedback for quality control. The typical test requires at least three specimens and is performed with single roll capacity for efficient workflow.

FAQs of Cross Hatch Adhesion Test Tape:

Q: How is the Cross Hatch Adhesion Test Tape used for coating adhesion evaluations?

A: The tape is manually applied to the surface and cut into cross-hatch patterns per ISO 2409 or ASTM D3359 standards. After peeling the tape, the area is visually assessed for coating removal, and results are rated on a 0-5 scale.Q: What surfaces can this adhesion test tape be applied to?

A: It is suitable for industrial surfaces including painted panels, plastics, and metal finishes, offering versatile application for manufacturers and laboratories.Q: When should the tape be applied during the testing process?

A: Apply the tape after preparing the test specimen and cutting the cross-hatch grid. Follow standard protocols for timing and procedure to ensure reliable results.Q: Where should the tape be stored to maintain its quality and shelf life?

A: The test tape should be stored in a cool, dry place away from direct sunlight and ambient humidity of 0-85% RH, helping preserve its adhesive strength throughout its 12-month shelf life.Q: What is the recommended temperature for conducting adhesion tests with this tape?

A: Testing should be performed between 10C and 35C to ensure accurate and repeatable results, as extreme temperatures may affect tape performance.Q: What are the benefits of using this test tape for adhesion testing?

A: It delivers high tack adhesive for reliable adhesion, clean removal without residue, and consistent thickness. This ensures accuracy and repeatability in qualitative coating assessments, making it ideal for industrial quality control.Q: Is the test result quantitative or qualitative, and how quickly is it obtained?

A: Assessment is qualitative, based on visual inspection in accordance with ISO 2409 or ASTM D3359. The result is immediate after the manual test and tape removal.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Inspection Category

Banana Gauge

Test Range : 0 200 mm

Mounting Type : Benchtop

Usage : Quality control, shape analysis in agriculture

Application : Banana shape measurement, straightness gauge for fruit

Features : Portable, robust, easy operation

Automation Grade : Semiautomatic

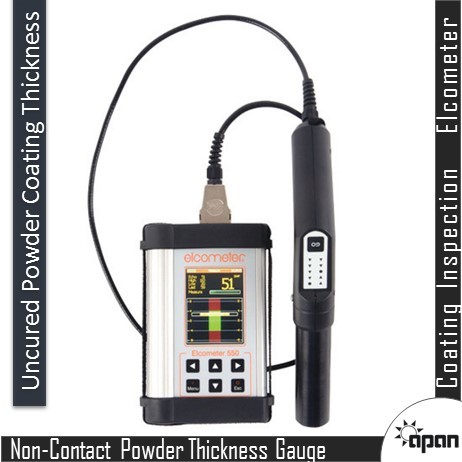

Non-Contact Powder Thickness Gauge

Test Range : 0~5 mm

Mounting Type : Tabletop

Usage : Industrial powder coating measurement

Application : Powder thickness measurement

Features : Noncontact measurement, high accuracy, digital display, fast response

Automation Grade : Automatic

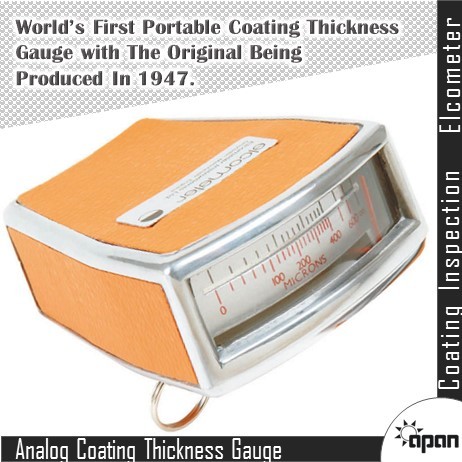

Analog Coating Thickness Meter

Test Range : 0 1000 m (microns)

Mounting Type : Handheld

Usage : Coating thickness measurement

Application : Measurement of dry film thickness on ferrous and nonferrous substrates

Features : Portable, Lightweight, Userfriendly

Automation Grade : Manual

Bresle Salt Kit

Test Range : 050 mg/m (Salt level)

Mounting Type : Handheld, portable

Usage : For testing soluble salt contamination on steel surfaces before painting/coating

Application : Surface contamination and salt residue analysis on steel and other metals

Features : Complete kit with full accessories, portable, field/lab use, fast results

Automation Grade : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry