Elcometer Paint Meter

Elcometer Paint Meter Specification

- Test Range

- 0 - 1500 m

- Application

- Coating Thickness Measurement

- Measuring Range

- 0 - 1500 m

- Mounting Type

- Handheld

- Display Type

- LCD Digital

- Operating Voltage

- 3V (2 x AA Batteries)

- Temperature

- -10C to 60C

- Features

- Auto Power Off, Data Hold, Zero Calibration

- Automation Grade

- Manual

- Accuracy

- 1% of reading 2 m

- Humidity

- 0% to 95% non-condensing

- Resolution

- 1 m

- Response Time

- Instant

- Equipment Type

- Paint Meter

- Power Supply

- 2 x AA Batteries

- Usage

- Paint, Powder Coating, Plating

- Machine Weight

- 140 g

- Test Speed

- Manual

- Control Mode

- Handheld

Elcometer Paint Meter Trade Information

- Main Export Market(s)

- Asia

About Elcometer Paint Meter

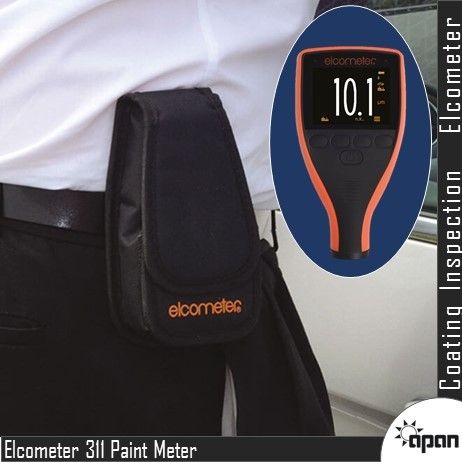

Elcometer Paint Meter

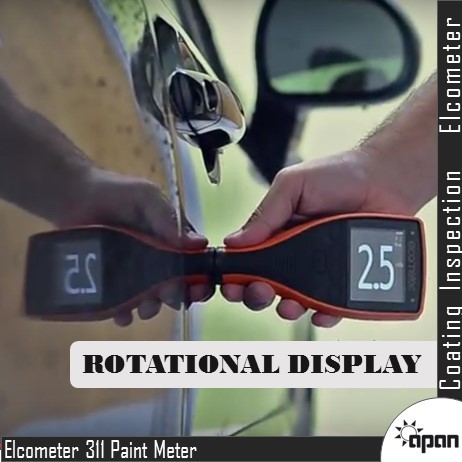

As an Authorized dealer we are engaged in providing the broad assortment of Elcometer, UK make Dry Film Coating Thickness (DFT) gauge. New Elcometer 311 Paint Meter is the fastest paint gauge on the market today, used to instantly measure paint thickness and provide an indication of the overall condition of paint work.

With instant material recognition, Paint Meter switches between steel and aluminium panels and is ideal for use in all climatic conditions.

The Elcometer 311 Paint Meter allows the user to quickly identify Paint danmage not reported in public or commercial condition reports including:

- Hidden rework

- Vehicle impact damage

- vehicle respray

- Filled body panels

Compatible with ElcoMaster software and ElcoMaster Mobile App, individual paint thickness readings can be transferred via USB or Bluetooth to PC or a mobile device for analysis and instant report generation.

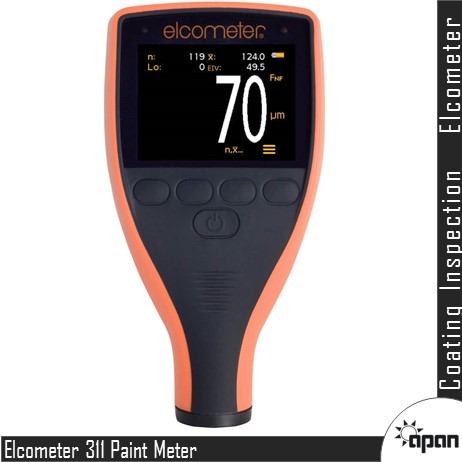

Specifications :

- Calibration Test Certificate

- Built in probe type : Steel (F) / Steel & Aluminium (FNF)

- On screen statistics

- Number of readings, n

- Average (mean), x

- Lowest reading, Lo

- Elcometer Index Value (EIV)

- Wireless Data output via Bluetooth or USB

- Fast accurate reading rate : 60+ readings per minute

- Accuracy : ±5% or ±20m (1.0mil)

- Resolution : 10micron (0.5mil)

- Minimum Substrate Thickness: Steel: 800m (30mils) / Aluminum: 300m (12mils) - FNF gauges only

- Measurement Range : 0-500micron (0-20mils)

- Operating Temperature : -10 to 50°C / 14 to 122°F

- Relative Humidity (RH) : 0 to 95% (RH)

- Power Supply : 2 x AA Batteries or via USB (rechargeable batteries can also be used)

Additional Accessories :

- Calibration Check Piece; Steel (Ferrous)

- Calibration Check Piece; Aluminum (Non-Ferrous)

- Calibration Check Foil; Nominal value 125 m (5mils)

- USB Cable

- Self Adhesive Screen Protectors (Pack of 10)

Standard Compatible :

- ISO 2808, ISO 2808-7C, ISO 2808-7D, ISO 2808-12A, ISO 2808-11B, ASTM E376, JIS K 5600-1-7, AS/NZS 1580.108.1

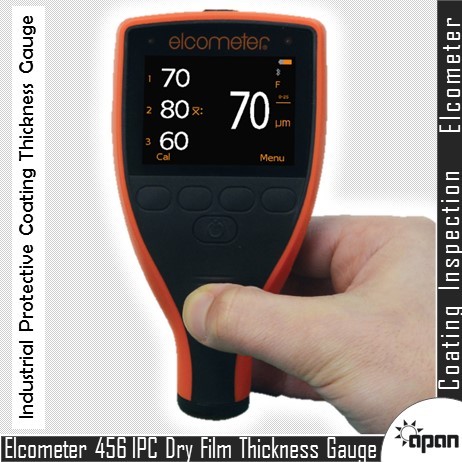

Advanced Measurement for Reliable Results

The Elcometer 456 combines a backlit digital LCD display with a straightforward, handheld design, making it perfect for field and laboratory coating thickness measurements. With instant response time and manual operation, users can efficiently record over 1500 readings (model dependent), whether inspecting paint, powder coatings, or plating on various substratesincluding ferrous and non-ferrous metals.

Optimized for Professional Applications

Engineered for compliance with global standards such as ASTM D7091 and ISO 2808, the Elcometer 456 ensures reproducible, traceable results. Suitable for use in harsh environments, its durable, lightweight build (140 g) and temperature/humidity resilience allow versatile deploymentideal for suppliers, exporters, and industrial professionals.

FAQs of Elcometer Paint Meter:

Q: How do I calibrate the Elcometer 456 Paint Meter for accurate measurements?

A: The Elcometer 456 is factory calibrated for immediate accuracy, but it also supports convenient in-field zero or two-point calibration to accommodate specific substrates and coating types. This allows you to maintain precision even with changing application conditions.Q: What types of surfaces and coatings can the Elcometer 456 measure?

A: You can use the Elcometer 456 Paint Meter to measure coating thickness on both ferrous (minimum substrate thickness of 0.3 mm) and non-ferrous substrates (minimum 0.2 mm). It is ideal for paint, powder coatings, and plating across a range of industrial applications.Q: When should I use the data storage feature on the Elcometer 456?

A: Data storage is beneficial when you need to log up to 1500 readings (depending on model) for later analysis or quality control reporting. This is especially useful during large-scale inspections or when you must maintain consistent records for compliance.Q: Where is the Elcometer 456 typically used?

A: This paint meter is commonly used in industrial environments, automotive facilities, shipping yards, laboratories, and by quality control professionals throughout India and worldwide, thanks to its robust design and international standards compliance.Q: What is the process for taking a coating thickness reading with this device?

A: Simply power on the Elcometer 456, select the appropriate probe (integrated or separate), apply it to the sample surface, and view the instant reading on the digital LCD display. Use data hold or storage features as needed.Q: How does the Elcometer 456 benefit quality assurance applications?

A: The Elcometer 456 offers precise, repeatable measurements at a high speed, ensuring products meet required coating standards. Its ease of calibration, reliable performance, and compliance with international norms make it an invaluable tool for minimizing coating defects and ensuring customer satisfaction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Inspection Category

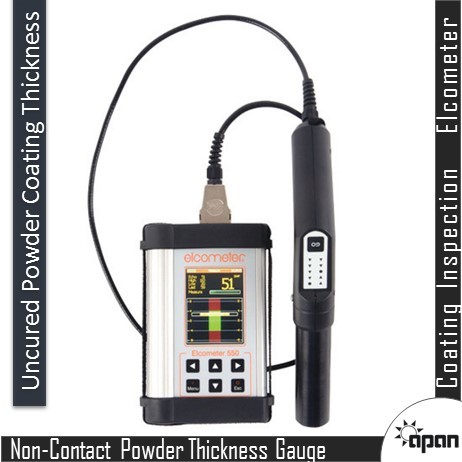

Non-Contact Powder Thickness Gauge

Features : Noncontact measurement, high accuracy, digital display, fast response

Control Mode : Automatic

Application : Powder thickness measurement

Mounting Type : Tabletop

Response Time : <1 s

Resolution : 0.001 mm

Ferrous Metal Coating Thickness Gauge

Features : Auto shut off, Low battery indicator, Portable design

Control Mode : Button / touch control

Application : Measurement of coating thickness on ferrous substrates

Mounting Type : Handheld

Response Time : <1 Second

Resolution : 1 m

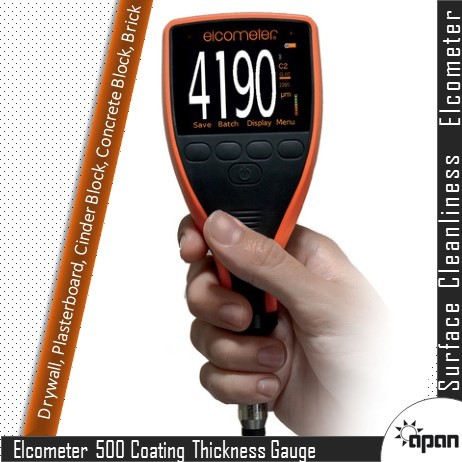

Elcometer 500 Concrete Coating Thickness Gauge

Features : Nondestructive, ergonomic, fast reading, rugged build, onscreen statistics, secure calibration memory

Control Mode : Manual

Application : Measures coating thickness on concrete substrates

Mounting Type : Handheld

Response Time : <1 second

Resolution : 1 m (0.1 mils)

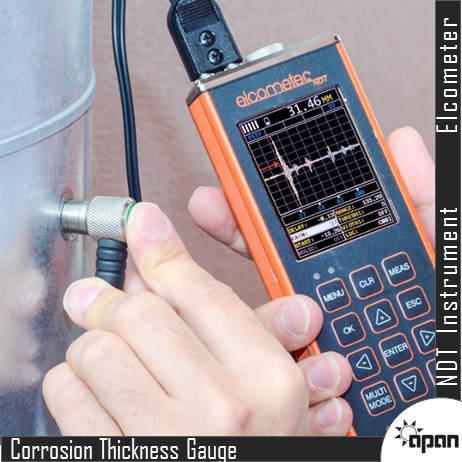

Corrosion Thickness Gauge

Features : Low battery indication, automatic shutdown, metric/imperial selectable, data hold

Control Mode : Manual

Application : Corrosion measurement, thickness testing of metals and other solid materials

Mounting Type : Handheld

Response Time : <1 second

Resolution : 0.1 mm/0.01 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry