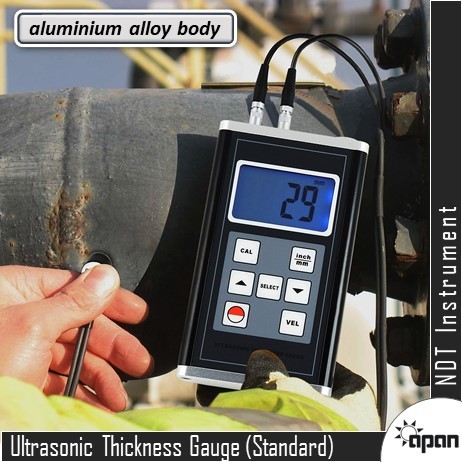

Ultrasonic Thickness Gauge (Standard)

Ultrasonic Thickness Gauge (Standard) Specification

- Test Range

- 1.2 - 225 mm (steel)

- Temperature

- 0 to 40C

- Power Supply

- 2 x 1.5V AA alkaline batteries

- Measuring Range

- 1.2 mm to 225 mm

- Operating Voltage

- 3V DC (2xAA)

- Accuracy

- (1%H+0.1) mm

- Interface Type

- BNC connector

- Automation Grade

- Manual

- Specimen Size

- Minimum diameter: 20 mm

- Frequency

- 5 MHz (standard probe)

- Display Type

- LCD digital display

- Application

- Thickness measurement of metal and non-metal components

- Mounting Type

- Handheld

- Resolution

- 0.1 mm

- Features

- Backlight display, Auto shutdown, Low battery indicator

- Port Size

- Standard probe port

- Humidity

- 85% RH

- Number of Specimens

- Single measurement

- Equipment Type

- Ultrasonic Thickness Gauge (Standard)

- Response Time

- 0.5 seconds

- Usage

- Industrial, Laboratory

- Machine Weight

- 200 g (approx)

- Test Speed

- Normal mode

- Control Mode

- Manual

- Sound Velocity Range

- 1000~9999 m/s adjustable

- Case Material

- ABS engineering plastic

- Probe Type

- Dual-element transducer

- Battery Life

- Up to 250 hours (without backlight)

- Dimension

- 133 mm x 70 mm x 30 mm

- Storage Temperature

- -10°C to 60°C

- Coupling Indicator

- Yes (on display)

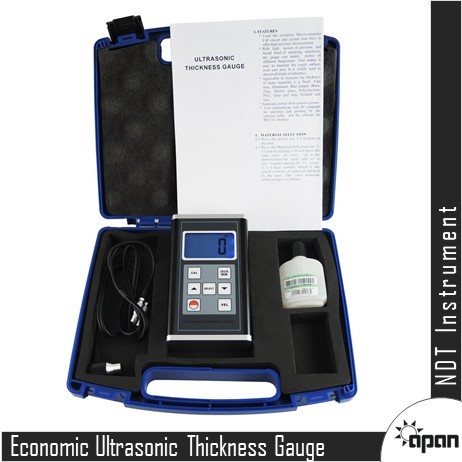

About Ultrasonic Thickness Gauge (Standard)

As an Authorized dealer we are engaged in offering wide gamut of NDT Instruments.

Handheld Ultrasonic Thickness Gauge with metal case and test range from 0.9400mm. Used for measuring thickness and corrosion of pressure vessels, chemical equipment, boilers, oil storage tanks, and more in industries of petroleum, ship building, power station and machine manufacturing. It uses the latest high performance and low power consumption microprocessor technology.

Applicable to measure the thickness of many materials, e.g. Steel, Cast iron, Aluminum, Red copper, Brass, Zinc, Quartz glass, Polyethylene, PVC, Gray cast iron, Nodular cast iron.

- Used the exclusive Micro-computer LSI circuit and crystal time base to offer high accuracy measurement.

- With high power of emission and broad of receiving sensitivity, the gauge can match probes of different frequencies. That makes it easy to measure the rough surface, even cast iron.

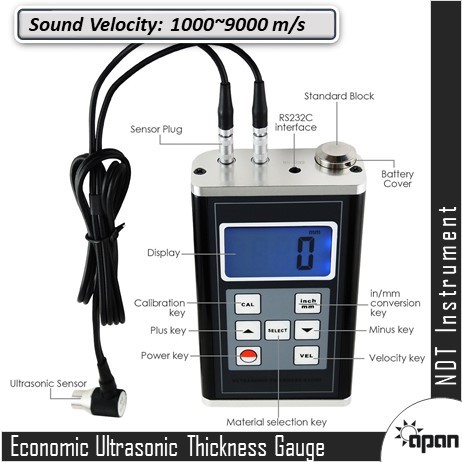

- Bidirectional measurement, for materials within measurement range, thickness is measurable with know velocity, Conversely velocity is measurable with know thickness.

- Automatic memory material code and sound velocity value, convenient to use

Automatic power off to conserve battery power

- Can communicate with PC computer for statistics and printing by the optional cable and the software for RS232C interface (not included in the set).

- Has CE marking, conforms with the essential health and safety requirements set out by the European Directives

Specifications:

- Display: digital 4 digit LCD

- Operating principle: ultrasonic

- Range: 0.9400mm (45# steel) R

- Resolution: 0.1mm / 0.01mm / 0.001 inch

- Accuracy: + 1 (0.5%n+0.1)

- Sound Velocity: 10009000 m/s

- Power off: auto and manual power off

- Battery indicator: low battery

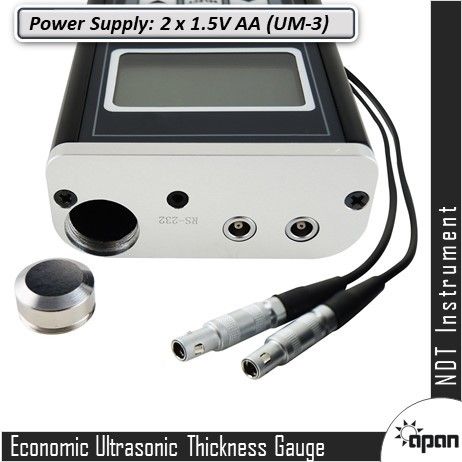

- Power Supply: 2 x 1.5V AA (UM-3)

- Operating Condition: Temperature: 040oC, Humidity: <80%

- Case material: aluminum alloy

- Size: 130 x 76 x 32mm

- Weight: about 340g (excluding batteries)

Highly Accurate Thickness Measurement

This Ultrasonic Thickness Gauge delivers exceptional accuracy with a resolution of 0.1 mm and a measuring range from 1.2 mm to 225 mm (for steel). Its dual-element transducer and selectable sound velocity ensure suitability for a wide variety of materials, making it invaluable for diverse industrial and laboratory settings.

Intuitive and Reliable Operation

Designed for convenience, this gauge features an easy-to-read LCD digital display with backlight, clear coupling indicator, quick response time of 0.5 seconds, and auto-shutdown functionality to save battery. The unit runs on standard AA batteries, offering portability and reliability for field use.

Durable Build for Robust Use

Constructed from ABS engineering plastic, this thickness gauge withstands rigorous industrial environments. Its compact size (133 mm x 70 mm x 30 mm) and lightweight design (approximately 200 g) ensure comfort during prolonged usage while maintaining excellent durability and longevity.

FAQs of Ultrasonic Thickness Gauge (Standard):

Q: How do I operate the Ultrasonic Thickness Gauge for accurate measurements?

A: To operate the gauge, attach the dual-element transducer to the specimen using a suitable couplant and ensure proper coupling as indicated on the display. Set the appropriate sound velocity for your material. Press the measurement button, and the device will display the thickness reading within 0.5 seconds with a resolution of 0.1 mm.Q: What types of materials can this thickness gauge measure?

A: This gauge is suitable for measuring the thickness of both metal and non-metal components, as long as their sound velocity is within the adjustable range of 10009999 m/s. It is commonly used in industrial, laboratory, and automation applications for quality assurance and corrosion monitoring.Q: When should I replace the batteries in the Ultrasonic Thickness Gauge?

A: Replace the 2 x 1.5V AA alkaline batteries when you see the low battery indicator on the display or if the device no longer powers on. With normal use and the backlight off, you can expect up to 250 hours of battery life.Q: Where is the Ultrasonic Thickness Gauge most effective for use?

A: It is highly effective in industrial and laboratory settings, including manufacturing plants, metal fabrication shops, and maintenance departmentsanywhere accurate and repeatable non-destructive thickness measurement is required.Q: What is the setup process for different types of specimens?

A: For best results, ensure the minimum diameter of the specimen is at least 20 mm. Apply couplant to improve ultrasonic transmission between the probe and the surface. Select or calibrate the sound velocity to match the material, and ensure a proper connection via the standard BNC connector.Q: How does the coupling indicator assist during testing?

A: The coupling indicator visually confirms on the LCD display when the probe is making a good acoustic connection with the test surface. This reduces the risk of measurement errors and improves reliability.Q: What are the key benefits of using this Ultrasonic Thickness Gauge?

A: Key benefits include rapid and accurate measurements, ease of use with a digital LCD display, extended battery life, portability due to compact design, and durability from an ABS engineering plastic case. Additional features like auto shutdown and low battery indicator maximize operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NDT Equipment Category

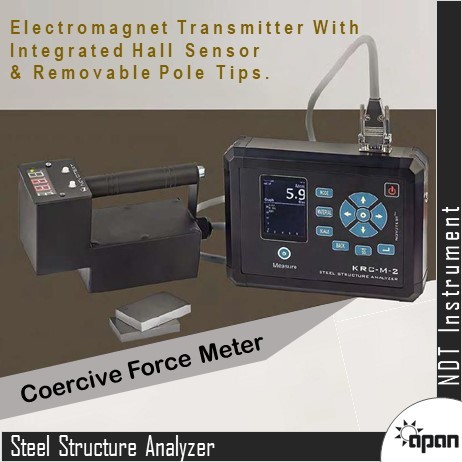

Steel Structure Analyzer

Humidity : 10% 85% RH

Features : Data Logging, RealTime Analysis, Automatic Calculation

Mounting Type : Benchtop

Application : Steel Structure Testing, Quality Assurance, Research & Development

Usage : Industrial / Laboratory

Response Time : 2 seconds

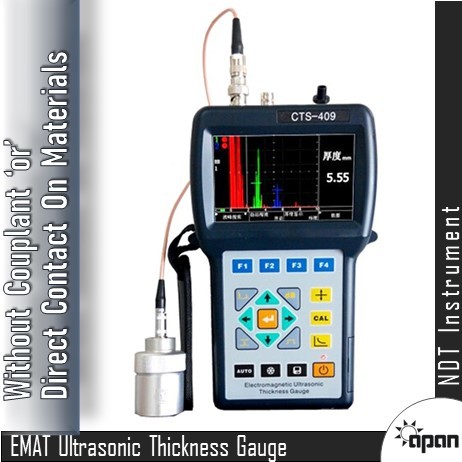

EMAT Ultrasonic Thickness Gage

Humidity : 85% RH

Features : Noncontact measurement, high penetration, suitable for rough and oxidized surfaces

Mounting Type : Handheld/Portable

Application : Nondestructive thickness measurement of conductive materials

Usage : Industrial, Laboratory, Field inspection

Response Time : 1 second

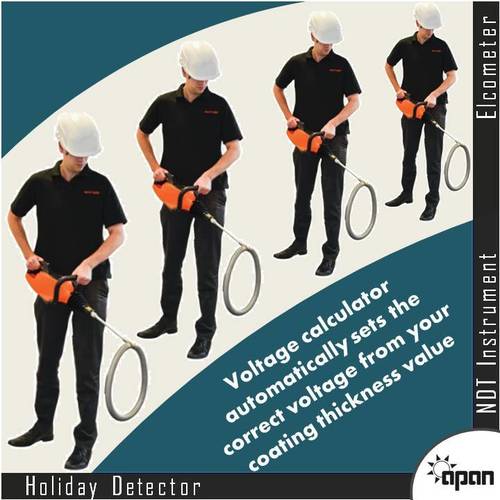

Elcometer 280 Pulsed DC Holiday Detector

Humidity : Up to 95% RH noncondensing

Features : Audible and visual alarms; adjustable pulse voltage; high voltage safety feature; external electrode compatibility

Mounting Type : Handheld

Application : Detects holidays (pinholes, porosity, flaws) in coatings on conductive substrates

Usage : Coating inspection; pipeline and tank lining testing

Response Time : Immediate/realtime

Magnetic Yoke

Humidity : Up to 85% RH

Features : Portable, Rugged, Easy operation

Mounting Type : Handheld

Application : Magnetic particle flaw detection

Usage : Industrial NonDestructive Testing (NDT)

Response Time : Immediate

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry