Elcometer 280 Pulsed DC Holiday Detector

Elcometer 280 Pulsed DC Holiday Detector Specification

- Resolution

- 0.1 kV

- Equipment Type

- Pulsed DC Holiday Detector

- Test Range

- DC Pulsed voltage 0.5kV30kV

- Number of Specimens

- Single specimen per test

- Frequency

- Pulse frequency up to 30Hz

- Measuring Range

- 0.5 kV to 30 kV

- Features

- Audible and visual alarms; adjustable pulse voltage; high voltage safety feature; external electrode compatibility

- Temperature

- Operating: -10C to +50C (+14F to +122F)

- Interface Type

- Keypad controls

- Accuracy

- (5% + 5 digits)

- Power Supply

- Rechargeable Li-ion battery pack, 12V DC, 4400mAh

- Humidity

- Up to 95% RH non-condensing

- Response Time

- Immediate/real-time

- Automation Grade

- Manual

- Application

- Detects holidays (pinholes, porosity, flaws) in coatings on conductive substrates

- Specimen Size

- Compatible with electrodes from 150mm to 450mm

- Operating Voltage

- 12V DC

- Mounting Type

- Handheld

- Display Type

- LCD digital display

- Usage

- Coating inspection; pipeline and tank lining testing

- Machine Weight

- Approx. 3.4kg (7.5lb) including wand but without electrodes

- Test Speed

- Manual (Dependent on user movement)

- Test Width

- Dependent on electrode size (varies)

- Test Stroke

- Variable; subject to application

- Control Mode

- Manual operation

- Color

- Industrial orange-grey

- Pulse Output

- Pulsed DC for low conductivity coatings

- Safety

- Automatic shutdown in high current situations

- Alarm Type

- Visual LED and loud buzzer

- Charging Time

- Approximately 8 hours

- Water Resistance

- IP54 (splash proof, dust protected)

- Dimensions

- 350mm x 220mm x 100mm (approx unit size)

- Operating Principle

- Detects discontinuities via voltage pulse through coating

- Electrode Types

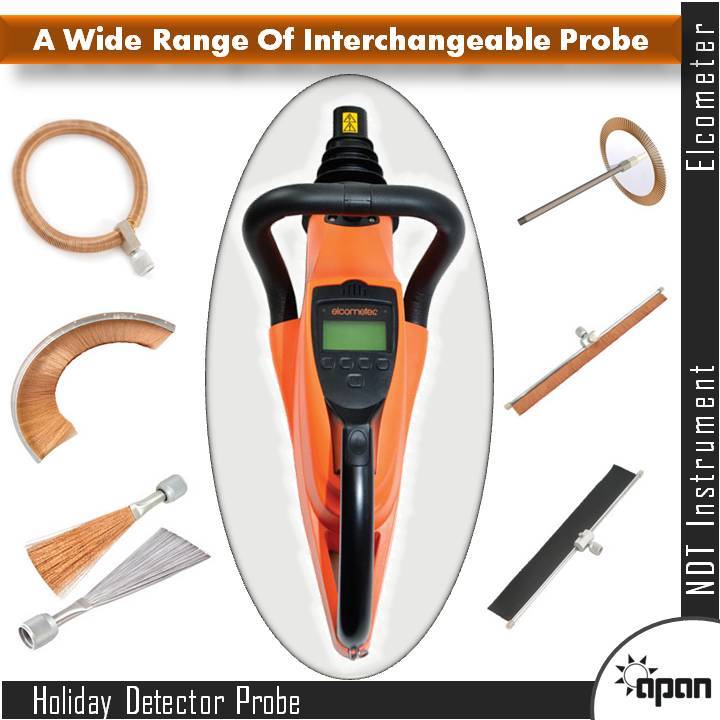

- Spring, wire brush, and rolling electrodes available

- Carrying Case

- Supplied for portability and equipment protection

- Electrode Connection

- Universal, quick-connect for various electrode types

- Compliance

- Meets International Standards ASTM D478, NACE SP0188, ISO 29601, AS 3894.1

- Battery Life

- Up to 9 hours

- Low Voltage Indicator

- Yes, for battery monitoring

- Electrode Diameter Range

- From 150mm (6") up to 460mm (18")

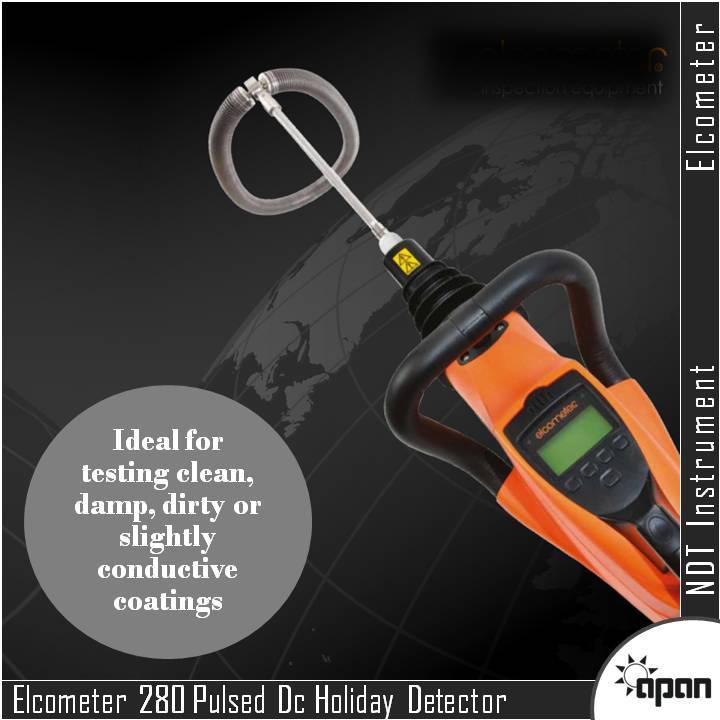

About Elcometer 280 Pulsed DC Holiday Detector

Fully charged in 4 hours and weighing only 3kg (6.6lb), the Elcometer 280 can provide up to 30 hours of continuous use.

Rugged, shockproof, water resistant and incredibly safe: with its two stage safety switch, bright LEDs, screen icons and buzzer signifying when the high voltage is on, extended ribbing to protect the user from spark creep, and much much more, the Elcometer 280 raises the bar in safe pulsed DC porosity detection.

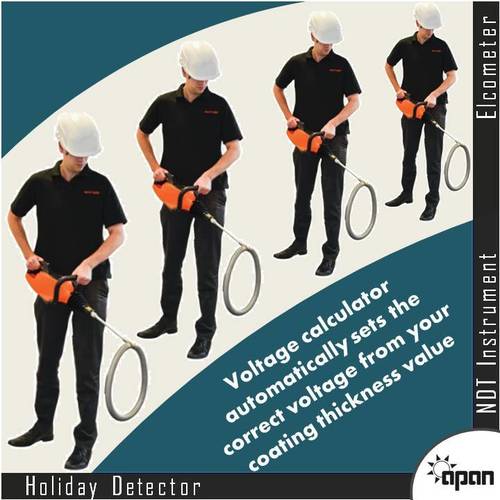

Users can either set the test voltage manually or can let the internal Voltage Calculator automatically set the gauge to the correct voltage required for their coating thickness value.

Supplied complete with 2 rechargeable battery packs (and charger), 5m (16) trailing earth lead, rolling spring holder and 250mm (9.8) extension rod; just select the appropriate probe electrode from the comprehensive range of accessories to suit your application.

The Elcometer 280 Holiday Detector Inspection Kit is supplied in a rugged, light weight wheeled transit case, designed to hold up to 6m (30) of stainless steel or up to 20m (66) of phosphor bronze rolling spring ideal for easy transportation to site.

The Elcometer 280 Pulsed DC Holiday Detector compliments the wide range of high voltage holiday detectors, low voltage and UV pinhole detectors available from Elcometer.

Using state of the art electronics, the Elcometer 280 allows users to inspect coatings - without connecting the earth return lead to the component substrate - ideal for inspecting large surfaces and pipelines.

Features

- Flashing display, bright LED and a user adjustable volume alarm indicates detection of a holiday

- 0.5 - 35kV range (user selectable) for detecting porosity in coatings up to 25mm (1") thick

- Safety trigger integrated inside the handle cuts power if released

- Rugged, shock proof and water resistant design to ensure long life - even in harsh environments

- Balanced, ergonomic design, complete with shoulder strap allows long periods of continuous use

- A wide range of interchangeable probe accessories available - compatible with all Elcometer holiday detectors - please order as a separate item.

- Ideal for testing clean, damp, dirty or slightly conductive coatings

- Voltage calculator automatically sets the correct voltage from your coating thickness value

- Internal jeeptester ensures that the selected voltage equals the test voltage

Comprehensive Electrode Compatibility

The Elcometer 280 supports a wide array of electrode types, including spring, wire brush, and rolling variants, allowing inspection of coatings over a broad surface range. Its universal quick-connect system ensures fast and secure attachment, facilitating adaptability and minimizing downtime during testing operations.

Optimized Portability and Safety

This holiday detector is designed for field use, featuring a lightweight build and an IP54 splash-proof, dust-protected casing. Integrated safety mechanisms automatically power down the device in high-current scenarios, providing an additional layer of operator protection. An included carrying case offers safe storage and transport between worksites.

Advanced Detection and User Interface

With a measuring range of 0.530kV and (5% + 5 digits) accuracy, the Elcometer 280 offers immediate, real-time detection displayed via a clear LCD screen. Audible and visual alarms signal flaw detection, while adjustable pulse voltage and keypad controls allow precision tuning for each inspection condition.

FAQs of Elcometer 280 Pulsed DC Holiday Detector:

Q: How does the Elcometer 280 Pulsed DC Holiday Detector identify flaws in coatings?

A: The detector applies a pulsed DC voltage through the coating using the selected electrode. If a discontinuity, such as a pinhole or flaw, is present, the voltage passes through and triggers both visual and audible alarms. This immediate indication allows inspectors to locate and mark repair areas efficiently.Q: What types of electrodes can be used with the Elcometer 280 and why is this beneficial?

A: The unit supports spring, wire brush, and rolling electrodes, covering diameters from 150mm to 460mm. This versatility enables adaptation to a variety of surfaces and coating thicknesses, from tanks to pipelines, enhancing the detectors suitability for multiple industrial coatings inspection scenarios.Q: When should I recharge the detectors battery, and how long does it last on a full charge?

A: The Elcometer 280 is equipped with a rechargeable Li-ion battery (12V DC, 4400mAh) that provides up to 9 hours of continuous operation. Recharge the device when the low voltage indicator alerts you or when extended testing is anticipated. Full charging takes approximately 8 hours.Q: Where can the Elcometer 280 be used, considering environmental and operational constraints?

A: Built to withstand field conditions, the detector can operate within temperatures from -10C to +50C and up to 95% relative humidity (non-condensing). Its IP54 rating provides splash and dust resistance, making it suitable for challenging environments like construction sites or outdoor pipeline inspections.Q: What is the process for setting up the detector for a test?

A: Simply connect the desired electrode using the quick-connect system, adjust the test voltage using keypad controls based on coating requirements, and begin manual inspection. The LCD display and alarm systems guide the operator during testing, ensuring accurate flaw detection.Q: How does the safety feature of automatic shutdown work during testing?

A: If the Elcometer 280 encounters a high current situation, it automatically shuts down to protect both the device and the operator. This high-voltage safety mechanism minimizes the risk of electrical hazards associated with holiday testing on conductive substrates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NDT Equipment Category

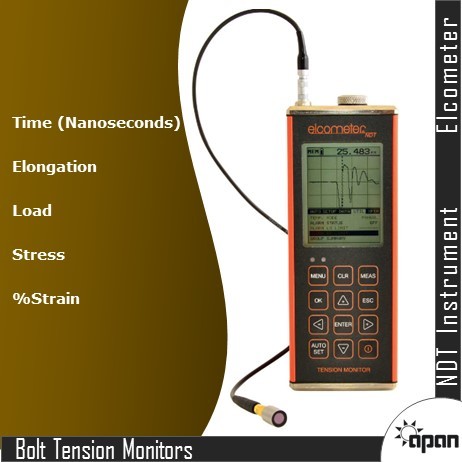

Bolt Tension Monitors

Usage : Bolt tension measurement

Control Mode : Digital

Test Range : 0100 kN

Equipment Type : Bolt Tension Monitor

Temperature : 0C to 50C

Features : Portable, High Accuracy, Data Logging

Precision Ultrasonic Thickness Gage

Usage : Industrial and laboratory measurement

Control Mode : Manual

Test Range : 1.0 200.0 mm (steel)

Equipment Type : Precision Ultrasonic Thickness Gage

Temperature : 10C to 60C

Features : Auto calibration, Low battery indication, Metric/Imperial unit switch, Backlit display

Precision Thickness Gauge

Usage : Laboratory and Industrial

Control Mode : Dial/Analog

Test Range : 010 mm

Equipment Type : Precision Thickness Gauge

Temperature : 5C~40C (Operating)

Features : Corrosion resistant body, Portable, Lightweight, Easy to use

Gauss meter

Usage : Magnetic field strength measurement

Control Mode : Manual

Test Range : 020 KiloGauss

Equipment Type : Digital Gauss Meter

Temperature : 0C to 50C

Features : Portable, Easytouse, Auto zero, high stability

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry