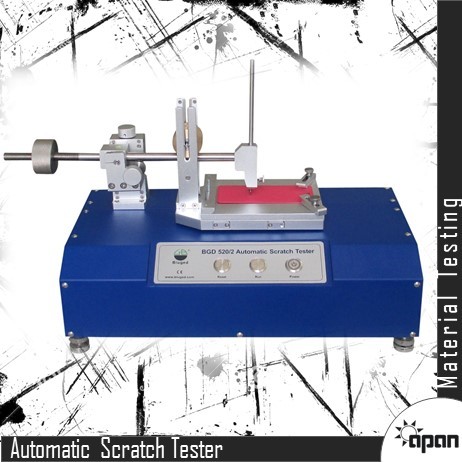

Automatic Scratch Tester

Automatic Scratch Tester Specification

- Features

- Microprocessor based, Programmable load, Adjustable speed, Audible warning

- Port Size

- Standard 6 mm

- Test Range

- 1N 50N

- Operating Voltage

- 220V

- Temperature

- 15-35C

- Accuracy

- 1%

- Measuring Range

- 1N 50N (Scratch Load)

- Number of Specimens

- 1

- Max Height

- 60 mm (Specimen thickness)

- Application

- Scratch Resistance Testing for Coatings, Paints, Platings, Sheets

- Response Time

- <1 sec

- Gas Pressure

- 0.4~0.7 MPa

- Humidity

- 30-80% RH

- Frequency

- 50 Hz

- Specimen Size

- 100 50 mm (max)

- Automation Grade

- Automatic

- Resolution

- 0.01 N

- Power Supply

- 220V AC, 50Hz

- Equipment Type

- Automatic Scratch Tester

- Display Type

- Digital LCD

- Mounting Type

- Table Top

- Interface Type

- RS232, USB

- Hardness

- Supports pencil & diamond stylus

- Usage

- Laboratory Testing

- Capacity

- Up to 100 tests/hour

- Machine Weight

- Approx. 30 kg

- Test Speed

- 10-200 mm/min (adjustable)

- Test Width

- 70 mm (max)

- Test Stroke

- 70 mm (adjustable)

- Control Mode

- Automatic & Manual

- Data Output

- Printable & Savable reports

- Scratch Length

- Up to 70 mm

- Safety Features

- Overload protection, Emergency stop

- Power Consumption

- 150 W

- Compliance Standards

- ISO 1518, ASTM D7027

- Stylus Type

- Diamond or Tungsten carbide (optional)

- Dimensions (LWH)

- 450 350 450 mm

About Automatic Scratch Tester

As an authorized dealer we are engaged in providing the broad assortment of Material Testing Equipment for various applicants.

Depending on the requirements, there are various methods for testing hardness. Some are dedicated to characterise coatings and others are more suitable for testing bulk materials such as metals, plastics, rubber or elastomers.

Scratch Resistance: To assess a coatings resistance to scratch there are a number of different instruments that can be used: Pencil Hardness Tester (Wolff-Wilborn), Sclerometer, Clemen Apparatus, Scratching and Shearing /Scratch Instrument.

Coatings and paints can protect, decorate substrate or conceal the defects of substrate, and these three functions are related with coatings hardness. And hardness is the important performance for paint mechanical strength, as well as the important indicator to judge paint quality. One of important indicators to evaluate coatings hardness is scratch resistance.

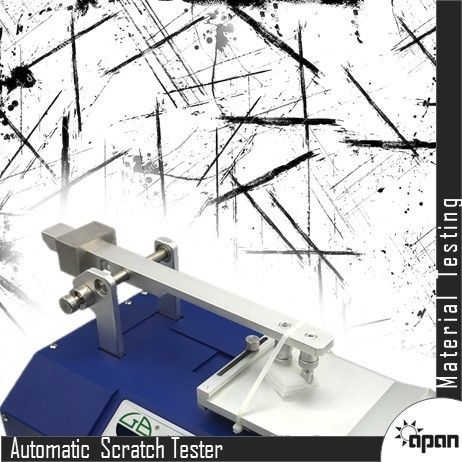

ISO 1518 Paints and varnishes -- Determination of scratch resistance specifies a test method for determining under defined conditions the resistance of a single coating or a multi-coat system of paint, varnish or related product to penetration by scratching with a scratch stylus loaded witha specified load. Penetration of the stylus is to the substrate, except in the case of a multi-coat system, in which case the stylus can penetrate either to the substrate or to an inter mediate coat.

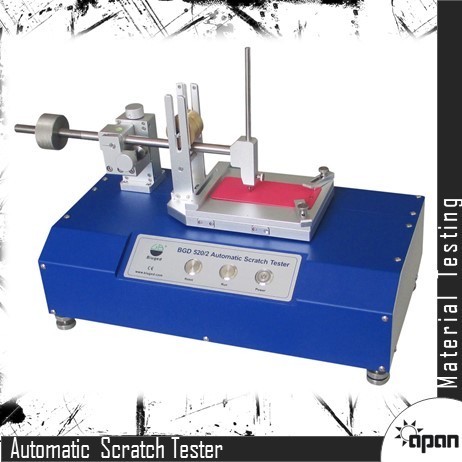

Automatic scratch test principle is to put a single or composite metal test plate fixed on the instrument work platform, when testing, working plat pull test plate at a rate of 30 to 40 mm/s to move slowly, at the same time, loading a load of hemispherical scriber slowly move reverse lines in the coating surface, if the scriber cuts coating, the scriber and test plate will show conductive between plates. The results are evaluated at a certain load whether the needle cuts through coating or a needle does not cut through of maximum load.

This test has been found to be useful in comparing the scratch resistance of different coatings. It is most useful in providing relative ratings for a series of coated panels exhibiting significant differences in scratch resistance.

- Big working table can be moved left and right convenient for measuring different areas in the same panel

- Special fixing device for sample---can test different size substrate

- Sound-light Alarm system for puncturing through sample panel---more visual

- High hardness material stylus--more durable

Specification

| Advance Model | Basic Model |

Conform standards | ISO 1518-1 BS 3900E2 | ISO 1518-2 |

Stylus | Having a hemispherical hard-metal tip of radius 0.25mm or 0.5mm Having a hemispherical synthetic-ruby of radius 0.25mm or 0.5mm | Coned sapphire or diamond, the tip radius is 0.03mm |

Angle between stylus and sample | 90 | 90 |

Weight | Constant-loading (0.5N1pc1N1pc2N2pcs5N1pc10N1pc | Variable-loading0g50g or 0g100g or 0g200g |

Motor | 60W 220V 50HZ | |

Sytlus Moving Speed | (355mm/s | 102mm/s |

Working Distance | 120mm | 100mm |

Max. Panel Size | 200mm100mm | |

Max. Panle Thickness | Less than 1mm | Less than 12mm |

Overall Size | 500260380mm | 500260340mm |

Net Weight | 17 KG | 17.5KG |

Advanced Scratch Testing for Diverse Materials

This automatic scratch tester is engineered for rigorous evaluation of coatings, paints, and platings, ensuring optimal scratch resistance. With its adjustable parameters and programmable loads, the system offers remarkable versatility for laboratory environments. Its microprocessor-based design allows consistent, repeatable testing, adhering to major international standards.

User-Friendly Operation and Precise Reporting

Featuring a digital LCD and both automatic and manual control modes, the tester provides intuitive use and straightforward navigation. Printable and savable reports enhance record-keeping and analysis, while the systems fast response time and reliable accuracy ensure all test results are delivered precisely.

Intelligent Safety Measures and Robust Design

Safety is prioritized with overload protection and an emergency stop feature. Housed in a sturdy table-top frame, the tester is suitable for busy laboratory settings. Its moderate size and weight make it accessible for a variety of laboratory setups, balancing portability with stability.

FAQs of Automatic Scratch Tester:

Q: How do I operate the Automatic Scratch Tester, and what control modes are available?

A: You can operate the tester using either the automatic or manual control modes, accessible via the digital LCD interface. Automatic mode allows for pre-programmed settings, while manual mode provides fine-tuned, on-demand adjustments during testing.Q: What materials and specimen sizes can this scratch tester handle?

A: The tester is suitable for coatings, paints, platings, and sheets, accommodating specimens up to 100 50 mm with a maximum thickness of 60 mm. Supported stylus types include diamond and tungsten carbide, and pencil hardness can also be evaluated.Q: When should I choose between a diamond and a tungsten carbide stylus?

A: Choose a diamond stylus for high-hardness materials and maximum durability testing. Tungsten carbide stylus is suitable for routine applications, cost-sensitive testing, and when evaluating softer coatings or substrates.Q: Where should this scratch tester be installed for optimal performance?

A: Install the unit on a stable, flat laboratory table, in an environment with temperatures between 15-35C and relative humidity levels of 30-80%. Ensure the location accommodates its dimensions (450 350 450 mm) and access to a 220V AC, 50Hz power supply.Q: What is the process for generating and exporting test reports?

A: After completing a test, the digital LCD enables you to generate detailed reports. These can be saved or printed via the RS232 or USB interface, ensuring seamless data management and compliance documentation.Q: How do the safety features benefit users during operation?

A: The built-in overload protection automatically halts operation if excessive force is detected, preventing instrument or sample damage. The emergency stop function ensures immediate shutdown in case of unexpected events, providing an additional layer of user safety.Q: What are the benefits of using this automatic tester for scratch resistance evaluation?

A: This tester offers accurate measurements (1%), easy handling of a wide range of sample types, fast processing (up to 100 tests/hour), and seamless compliance with international standards, making it ideal for laboratories requiring dependable, reproducible scratch resistance data.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Vickers Hardness Measuring System

Mounting Type : Benchtop

Usage : Metallurgical, Research Labs, Industrial Testing

Hardness : Vickers (HV)

Equipment Type : Hardness Measuring System

Application : Material Hardness Testing

Control Mode : Digital/Automatic

Digital Portable Hardness Tester with Printer

Mounting Type : Handheld/Portable

Usage : Onsite hardness testing, industrial

Hardness : Leeb (HL), converts to HRC, HB, HV, HS, HRB

Equipment Type : Digital Portable Hardness Tester

Application : Metal hardness measurement (steel, cast steel, alloy, copper, etc.)

Control Mode : Digital, Automated

Digital Micro Vickers Hardness Tester

Mounting Type : Benchtop

Usage : Vickers and Knoop hardness testing

Hardness : 1 3000 HV

Equipment Type : Digital Micro Vickers Hardness Tester

Application : Microhardness measurement for metals and alloys

Control Mode : Digital/Automatic

Elcometer Shore Durometer

Mounting Type : Handheld

Usage : Hardness testing of nonmetallic materials

Hardness : 0 to 100 Shore A (or D)

Equipment Type : Handheld Shore Durometer

Application : Measurement of hardness of rubber, plastic and other nonmetallic materials

Control Mode : Analog

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry