Bresle Salt Kit

Bresle Salt Kit Specification

- Features

- Complete kit with full accessories, portable, field/lab use, fast results

- Humidity

- Suitable for laboratory or field environment

- Application

- Surface contamination and salt residue analysis on steel and other metals

- Temperature

- Operating range: 5C to 40C

- Power Supply

- Not required (manual kit)

- Number of Specimens

- Test up to 25 samples per kit

- Resolution

- 0.1 mg/m

- Specimen Size

- Test area approx. 12 cm

- Mounting Type

- Handheld, portable

- Interface Type

- Manual/handheld

- Automation Grade

- Manual

- Display Type

- Solution test with visual comparison/chart

- Measuring Range

- 050 mg/m (NaCl equivalent)

- Response Time

- 1015 minutes per test

- Test Range

- 050 mg/m (Salt level)

- Accuracy

- 5% of measured value

- Usage

- For testing soluble salt contamination on steel surfaces before painting/coating

- Capacity

- 25 tests per kit

- Machine Weight

- Kit Weight: Approx. 350 g

- Test Speed

- Manual operation

- Control Mode

- Manual

- Shelf Life

- 24 months from date of manufacture

- Storage Conditions

- Store at room temperature away from direct sunlight

- Conductivity Measurement Range

- 01999 S/cm

- Equipment Type

- Bresle Method Salt Test Kit

- Sample Volume per Test

- 3 ml

- Sample Parameter

- Soluble salts (NaCl and other chlorides)

- Kit Contents

- Bresle Patches (25 Pcs), Extraction Syringe, Conductivity Meter, Calibration Solution, 125 ml DI Water, Sample Cups, Carry Case, Instructions Manual

- Cleaning Method

- Rinse components with DI water after use

- Patch Size

- 47 mm x 47 mm

Bresle Salt Kit Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

About Bresle Salt Kit

Surface preparation is one of the most important factors in the successful a coating or surface treatment and is critical to the effective lifetime of the coating. For any coating to perform successfully it is essential that the substrate is prepared properly.

Kit Content:

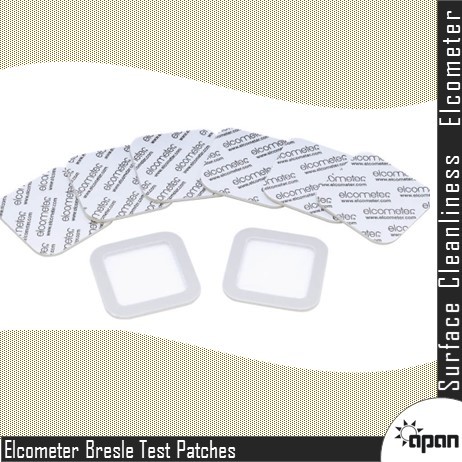

- Elcometer 135C Bresle Test Patch

- Elcometer 138E Conductivity Meter

- Standard Calibration Solution

- Bottle of Pure Distilled Water

- Syringes & Needles

- Plastic Beaker

- Batteries, Transit Case & User Guid

- Easy to peel off after test, leaving no foam on the substrate

- 19% thicker foam walls than traditional patches - easier to insert a needle

- Sealed compartment with clear flexible membrane for sampling soluble impurities

- Covers on both sides to protect against dust and contaminants

- Supplied with a Certificate of Cleanliness & Test Area

- Available in boxes of 25 & 100

Product details

| Dimensions | 149 mm x 27 mm x 16 mm |

| Test Area | 12.5 cm x 12.5 cm |

| Sample Volume | 1.5 ml to 2.0 ml |

| Patch Size | 5.2 cm x 5.2 cm |

| Measurement mode | Conductivity. sodium chloride (NaCl) salinity conversion |

| Display type | Liquid Crystal Display |

Comprehensive Surface Salt Testing

Designed for both field and laboratory environments, the Bresle Salt Kit provides all necessary tools for testing soluble salt contamination on metal surfaces. Its manual operation, portability, and included accessories make it an essential kit for ensuring surface integrity before painting or coating operations.

High Accuracy and Fast Results

With an accuracy of 5% and a resolution of 0.1 mg/m, this kit delivers precise results in just 1015 minutes. The devices visual comparison chart and clear instructions make the testing process straightforward, enabling confident decision-making across a wide measuring range.

User-Friendly and Durable

Each component, including the conductivity meter and calibration solution, is designed for longevity and consistent performance. The robust carry case and simple cleaning methodwith only DI waterensure easy transport, storage, and reuse, helping maintain testing quality over time.

FAQs of Bresle Salt Kit:

Q: How do I perform a salt contamination test using the Bresle Salt Kit?

A: To conduct a test, carefully place a Bresle Patch onto the clean surface of the metal specimen, inject 3 ml of DI water using the provided syringe, and extract the solution after a set contact time. Measure the conductivity of the extracted sample with the conductivity meter and compare the reading with the provided chart to determine salt levels.Q: What samples and surfaces can the kit be used on?

A: The kit is designed for analyzing soluble salts, mainly NaCl and other chlorides, on steel and various metal surfaces. Its ideal for testing prior to painting or coating, ensuring surfaces are free from contaminants that could affect adhesion or cause corrosion.Q: When should I use the Bresle Salt Kit during my workflow?

A: Use the kit before applying any paint or protective coating to metal surfaces, especially after cleaning or blasting. This ensures salt contamination is detected and addressed, promoting lasting coating performance.Q: Where can I use the kit, and under what environmental conditions?

A: Suitable for both laboratory and field environments, the kit operates effectively between temperatures of 5C and 40C. Store the kit at room temperature, away from direct sunlight, for optimal performance and preservation.Q: What is the process for cleaning and maintaining the kit components?

A: After each test, rinse all reusable components, such as the syringe and sample cups, with deionized water (DI water) to remove salt residues. This simple cleaning method helps ensure consistent accuracy and extends the kits service life.Q: What are the main benefits of using the Bresle Salt Kit?

A: Key benefits include its complete, portable setup, rapid result delivery (within 1015 minutes), high measurement accuracy, and ability to test up to 25 samples per kit. It enables users to make informed decisions about surface preparation, enhancing coating durability and reducing maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Inspection Category

Banana Gauge

Control Mode : Manual or Automatic

Application : Banana shape measurement, straightness gauge for fruit

Equipment Type : Banana Gauge

Features : Portable, robust, easy operation

Humidity : 20% 80% RH (noncondensing)

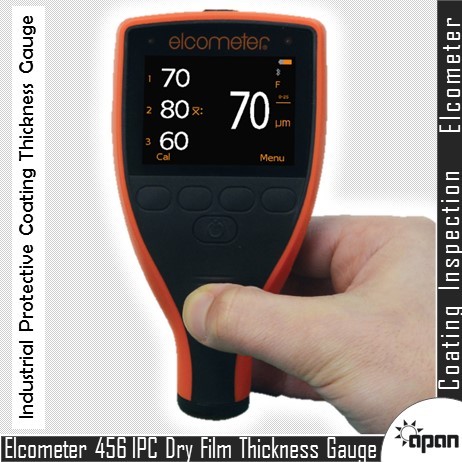

Ferrous Metal Coating Thickness Gauge

Control Mode : Button / touch control

Application : Measurement of coating thickness on ferrous substrates

Equipment Type : Ferrous Metal Coating Thickness Gauge

Features : Auto shut off, Low battery indicator, Portable design

Humidity : 85% RH

Cross Hatch Adhesion Test Tape

Minimum Order Quantity : 1 Piece

Control Mode : Manual

Application : Coating Adhesion Test, Paints, Plastics, Metal Finishes

Equipment Type : Adhesion Test Tape

Features : High Tack Adhesive, Clean Removal, Consistent Thickness

Humidity : 085% RH (Tape to be stored at ambient humidity)

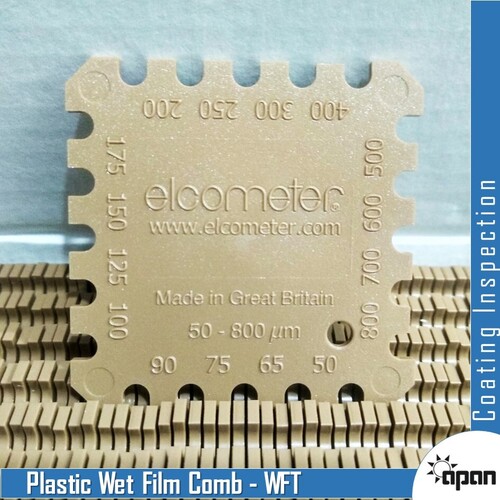

Plastic Wet Film Combs

Minimum Order Quantity : 1 Kit

Control Mode : Manual

Application : Measuring wet film thickness of paints, coatings and similar materials

Equipment Type : Plastic Wet Film Comb

Features : Corrosion resistant, lightweight, easy to use, nonreactive

Humidity : 0100% (ambient, nonsensitive)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry