Digital Compression Testing Machine

Digital Compression Testing Machine Specification

- Number of Specimens

- Single Specimen

- Measuring Range

- 0 - 2000 kN

- Display Type

- Digital LED Display

- Application

- Compression Strength Testing for Materials

- Accuracy

- 1% of displayed value

- Interface Type

- RS232, USB

- Mounting Type

- Floor Mounted

- Hardness

- Heavy Duty Cast Iron

- Operating Voltage

- 220 V

- Humidity

- Up to 90% RH

- Temperature

- 10C to 40C

- Test Range

- 0 - 2000 kN

- Port Size

- Standard 25 mm

- Specimen Size

- 150 mm x 150 mm x 150 mm

- Features

- Auto peak hold, Overload protection, Real-time data output

- Response Time

- <1 Second

- Power Supply

- 220 V AC, 50 Hz

- Automation Grade

- Automatic

- Resolution

- 0.1 kN

- Max Height

- 370 mm

- Equipment Type

- Digital Compression Testing Machine

- Frequency

- 50 Hz

- Usage

- Material Testing

- Capacity

- 2000 kN

- Machine Weight

- Approx. 350 kg

- Test Speed

- 0.2 - 1 mm/min adjustable

- Test Width

- 150 mm

- Test Stroke

- 100 mm

- Control Mode

- Digital, Automatic

- Cooling

- Passive cooling system

- Colour

- Industrial Grey with Black Accents

- Display Unit

- Bright LED alpha-numeric panel

- Noise Level

- <50 dB

- Data Storage

- Internal memory for up to 500 records

- Load Indicator

- Microprocessor based digital load indicator

- Calibration

- Factory calibrated with calibration certificate

- Indication Type

- Direct load and stress reading

- Safety Feature

- Emergency stop switch

- User Interface

- Simple touch-button control

- Operating Environment

- Indoor, dust free area

- Compression Plates

- Polished hardened steel

- Compressive Rate Control

- Stepless electronic control

- Signal Processing

- High precision analog to digital conversion

- Maintenance

- Low maintenance design

- Data Output

- USB and RS232 for PC connectivity

- Material of Frame

- Epoxy coated steel frame

- Overload Protection

- Built-in electronic circuit

About Digital Compression Testing Machine

As a Authorized dealer we are engaged in providing the broad assortment of Material Testing Instruments for wide range of material Testing applications.

Digital Compression Testing Machine

Max. test force | 2000 KN |

Load range | 0 - 2000kN |

Load accuracy | ± 1% from 2% to 100% of machine capacity |

Load resolution | 0.1 kN (20000 counts) |

Testing space | 240 × 240 × 80~450 mm |

Piston max. stroke | 50 mm |

Standard | Comply with ISO or other standards ISO7500, ISO6892 |

Motor power | 0.75 kW |

Machine size | 850 × 500 × 1480 mm |

Approximate weight | 800Kg |

Rated voltage | 440V 3 Phase AC supply 50 Hz |

Working temperature | 0~50OC |

Panel features | Display : 20 characters, 4 lines |

| Peak load hold Display |

Optional | Elongation measurement facility |

Computerized Models is also available | |

Servo Model is can be supplied | |

PACE Rate Control facility |

High Precision Performance

Equipped with high-precision analog-to-digital conversion and a microprocessor-based indicator, this machine assures reliable and accurate compression strength measurements for a range of materials. The auto peak hold and real-time data output features enhance testing efficiency.

User-Friendly Operation and Safety

The machines touch-button interface and bright LED alpha-numeric panel simplify operation, while features like the emergency stop switch and built-in electronic overload protection ensure maximum safety during testing procedures.

Robust Construction and Low Maintenance Design

Fabricated with a heavy-duty epoxy coated steel frame and polished hardened steel plates, the unit promises durability and stability. Its passive cooling system and low maintenance design minimize downtime, making it ideal for continuous indoor use in industrial environments.

FAQs of Digital Compression Testing Machine:

Q: How is the Digital Compression Testing Machine calibrated before use?

A: The machine is factory calibrated and comes with an official calibration certificate, ensuring measurement accuracy right from installation. Regular calibration verification is recommended for sustained precision.Q: What materials can be tested with this Compression Testing Machine?

A: This equipment is suitable for compression testing across a variety of materials such as concrete, cement blocks, and other construction specimens with dimensions up to 150 mm x 150 mm x 150 mm.Q: Where should the compression testing machine be installed for optimal operation?

A: It should be set up indoors, preferably in a dust-free and controlled environment where the ambient temperature ranges between 10C and 40C, and humidity does not exceed 90% RH to ensure reliable results and longevity.Q: What is the process for storing and exporting test data?

A: Test records are automatically saved in the internal memory, which can retain up to 500 results. Data can be exported effortlessly to a PC using the provided USB or RS232 interface for further analysis or reporting.Q: How does the overload protection feature benefit users during operation?

A: The built-in electronic overload protection continuously monitors for excess load and prevents equipment damage, ensuring operator safety and extending the machines service life.Q: When should users engage the emergency stop switch?

A: The emergency stop switch should be promptly activated in any situation where immediate cessation of machine activity is necessary, such as a malfunction or unexpected specimen failure during testing.Q: What are the advantages of the low maintenance design?

A: The passive cooling system and robust frame minimize routine maintenance needs, reducing operational downtime and overall cost of ownership for high-volume testing facilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Hydraulic Brinell Hardness Tester

Application : Metallurgical, foundries, forging industry, and quality control labs

Control Mode : Manual Hydraulic

Hardness : Brinell

Humidity : Up to 90% RH, noncondensing

Temperature : 10C to 40C

Test Range : 8650 HBW

Magnetic Rockwell Hardness Tester

Application : For hardness testing of ferromagnetic materials

Control Mode : Manual

Hardness : Rockwell C (HRC) Scale

Humidity : 85% RH

Temperature : 10C 40C

Test Range : 20100 HRC (Rockwell scale)

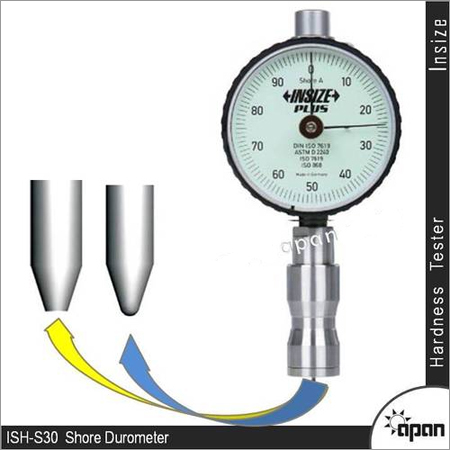

Shore Durometer Tester

Application : Measuring Hardness of Rubber, Elastomers, and Soft Plastics

Control Mode : Analog

Hardness : Shore A Scale

Humidity : 080% RH

Temperature : 0C to 40C

Test Range : 0~100 HA

Barcol Impressor Hardness Tester

Application : Hardness testing of aluminium, aluminium alloys, FRP, plastics and soft metals

Control Mode : Manual

Hardness : Reads Barcol Hardness Value

Humidity : 85% RH (operating range)

Temperature : 0C 40C (operating range)

Test Range : Barcol 0100 units

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry