Hydraulic Brinell Hardness Tester

Hydraulic Brinell Hardness Tester Specification

- Operating Voltage

- 230 V AC

- Display Type

- Analog Dial/Scale

- Hardness

- Brinell

- Resolution

- 0.1 HBW

- Max Height

- 380 mm (Vertical Clearance)

- Specimen Size

- Up to 380 mm height x 230 mm depth

- Features

- Robust construction, reliable hydraulic loading, user friendly operation

- Test Range

- 8-650 HBW

- Power Supply

- 230 V, 50 Hz, Single Phase

- Interface Type

- Manual, No Digital Interface

- Mounting Type

- Table Top

- Temperature

- 10C to 40C

- Response Time

- Instantaneous

- Port Size

- Standard 10 mm

- Equipment Type

- Brinell Hardness Tester

- Frequency

- 50 Hz

- Number of Specimens

- Single Specimen Test

- Measuring Range

- 8-650 HBW

- Humidity

- Up to 90% RH, non-condensing

- Automation Grade

- Manual

- Application

- Metallurgical, foundries, forging industry, and quality control labs

- Accuracy

- 1% of reading

- Usage

- Brinell Hardness Measurement

- Capacity

- Up to 3000 kgf

- Machine Weight

- Approx. 100 kg

- Test Speed

- Adjustable

- Test Width

- up to 150 mm

- Test Stroke

- 100 mm

- Control Mode

- Manual Hydraulic

- Certified Standards

- IS 2281, ASTM E10, BS 240, JIS Z2243

- Safety Features

- Overload protection, non-return valve

- Indenter Type

- 10 mm Hard Alloy Ball

- Scale Graduation

- 0.5 mm

- Color

- Blue/Gray

- Frame Material

- Cast Iron

- Base Size

- 220 x 460 mm

- Operating Mechanism

- Hand Lever Operated

- Oil Reservoir Type

- Built-in Tank

- Finish

- Powder Coated, Anti-corrosive

- Test Force Settings

- 500, 750, 1000, 1500 and 3000 kgf

Hydraulic Brinell Hardness Tester Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

About Hydraulic Brinell Hardness Tester

Authorized Dealer

Product details

| Opening Dimension | 350mm ( Height) * 100mm (Throat depth) |

| Display Type | Analog |

| Test Range | 32 to 650HBW |

| Test Force | 3000kgf, 000 kgf, 750 kgf, 500 kgf optional |

| Parameter | HBW |

| Test Force Error | 1% |

| Test Ball | 10mm Carbide test ball. 5mm optional |

Precision and Durability for Metallurgical Needs

This Brinell Hardness Tester stands out for its robust construction and precise hydraulic loading system. Designed for consistent performance in metallurgical environments, the machine adapts to various test forces and is built with a cast iron frame, providing stability during operations. The powder-coated, anti-corrosive finish ensures longevity, even in challenging industrial settings.

User-Friendly Operation and Safety Assured

Operation is straightforward using the manual hand lever and analog dial. Safety features like overload protection and a non-return valve safeguard both user and device. Adjustable test speed and an ergonomic table-top design make it suitable for quality control tasks, with minimal training required for effective usage.

Standards-Compliant and Versatile Application

The tester complies with internationally recognized standards (IS 2281, ASTM E10, BS 240, JIS Z2243), ensuring trustworthy results. Its versatility allows for testing a broad spectrum of specimensup to 380 mm in height and 230 mm in depthcatering to the needs of foundries, forging units, and research laboratories.

FAQs of Hydraulic Brinell Hardness Tester:

Q: How does the Hydraulic Brinell Hardness Tester operate?

A: The tester functions through a manual hydraulic system, activated by a hand lever. This mechanism applies selected test forces ranging from 500 to 3000 kgf onto the specimen using a 10 mm hard alloy ball indenter. The reading is displayed instantly via an analog dial/scale.Q: What are the main safety features incorporated in this hardness tester?

A: To ensure safe operation, the machine is equipped with overload protection and a non-return valve. These features help prevent mechanical damage and ensure stable, reliable test results.Q: When is it best to use this tester in an industrial environment?

A: This hardness tester is ideal for metallurgical labs, foundries, and forging industries where high-accuracy Brinell hardness measurements are required on metal specimens of various sizes and strengths.Q: Where can the Brinell Hardness Tester be installed?

A: With its table top mounting and compact base size, this tester can be installed in laboratories, quality control rooms, or production facilitiesanywhere a sturdy, flat surface is available.Q: What is the process for conducting a hardness test using this equipment?

A: Place the specimen on the base, select the desired test force, and use the hand lever to apply pressure via the hydraulic mechanism. The indentation is measured on the analog dial or scale, providing an accurate HBW (Brinell Hardness Number) reading instantly.Q: What are the primary benefits of using this manual hydraulic Brinell tester?

A: It offers high precision, a wide testing range (8-650 HBW), robust construction for long-term durability, and minimal maintenance requirements. The anti-corrosive finish and safety features further enhance operational reliability, making it a cost-effective choice for industries.Q: Can the tester accommodate large specimens or only small samples?

A: The equipment is designed for versatility, handling single specimens up to 380 mm in height and 230 mm in depth, making it suitable for a variety of part sizes encountered in industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Automatic Digital Rockwell Hardness Tester

Control Mode : Automatic digital

Application : Metals, alloys, heattreated materials hardness testing

Machine Weight : 95 kg

Usage : Laboratory/industrial material hardness measurement

Specimen Size : 2~70 mm (height)

Response Time : Instantaneous upon test

Digital RockwellHardness Tester

Control Mode : Automatic Loading/Unloading

Application : Hardness testing of metals and alloys

Machine Weight : 90 Kg approx

Usage : Industrial laboratory, material analysis

Specimen Size : 2 mm to 60 mm

Response Time : Instantaneous digital reading

Leeb Hardness Tester

Control Mode : Manual

Application : Testing the hardness of steel, cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminium, brass, bronze, copper, and other materials

Machine Weight : Approximately 350 g (including probe)

Usage : Nondestructive hardness testing of metals

Specimen Size : Minimum mass: 2 kg (with coupling), Minimum thickness: 3 mm

Response Time : Immediate (realtime display)

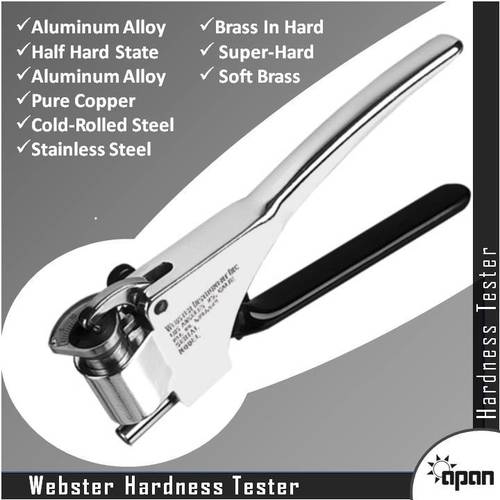

Webster Hardness Tester

Control Mode : Manual

Application : Onsite rapid hardness testing of aluminum alloys, copper, brass etc.

Machine Weight : 0.5 kg

Usage : Industrial, QA/QC, Laboratory

Specimen Size : Up to 13 mm thickness, standard jaw length

Response Time : Immediate

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry