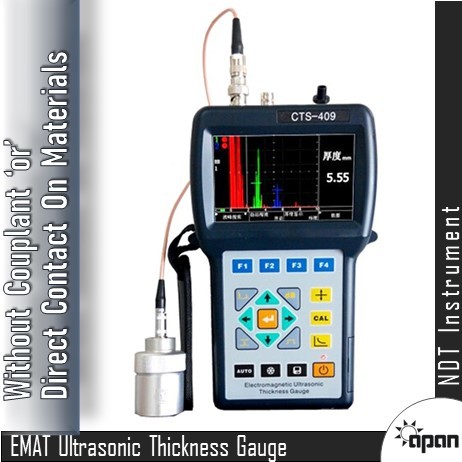

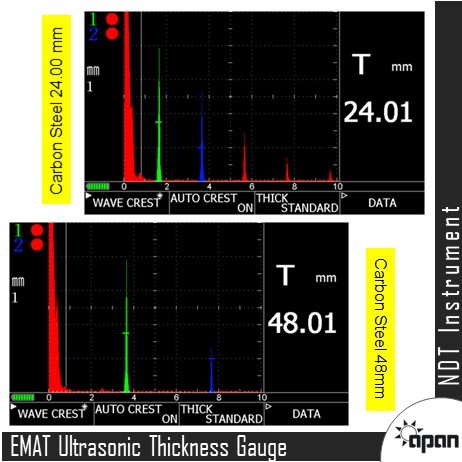

EMAT Ultrasonic Thickness Gage

EMAT Ultrasonic Thickness Gage Specification

- Interface Type

- USB, RS232

- Operating Voltage

- 220V AC

- Temperature

- -20C~+60C

- Display Type

- Digital LCD

- Mounting Type

- Handheld/Portable

- Application

- Non-destructive thickness measurement of conductive materials

- Humidity

- 85% RH

- Max Height

- Handled manually, no max height limitation

- Equipment Type

- EMAT Ultrasonic Thickness Gage

- Features

- Non-contact measurement, high penetration, suitable for rough and oxidized surfaces

- Accuracy

- 0.02 mm

- Port Size

- Standard BNC for probe connection

- Power Supply

- AC 220V, 50/60Hz

- Automation Grade

- Semi-automatic

- Number of Specimens

- Single point or continuous

- Test Range

- 0.8150 mm (steel equivalent)

- Specimen Size

- Minimum 15 mm width

- Gas Pressure

- Not required (Non-contact)

- Resolution

- 0.01 mm

- Frequency

- 2.5 MHz/5 MHz (selectable)

- Response Time

- 1 second

- Measuring Range

- 0.8150 mm

- Usage

- Industrial, Laboratory, Field inspection

- Machine Weight

- 2.7 kg

- Test Speed

- Up to 50 mm/s

- Test Width

- Variable depending on probe

- Test Stroke

- Adjustable

- Control Mode

- Manual/Automatic

- Firmware Update

- USB software upgradable

- Alarm Mode

- High/Low setpoint alert

- Battery Type

- Rechargeable lithium-ion

- Transducer Type

- Electromagnetic Acoustic Transducer (EMAT)

- Data Storage

- Internal memory for 2000 readings

- Dimensions

- 235 x 90 x 45 mm

- Material Compatibility

- Ferromagnetic and conductive metals

- Calibration

- Single-point and two-point calibration modes

- Battery Life

- Up to 10 hours continuous use

- Language Support

- English, Chinese (others optional)

- Protection

- IP54 rated housing

EMAT Ultrasonic Thickness Gage Trade Information

- Packaging Details

- 1 set of CTS-409 EMAT Thickness Gauge, 1 Power Adapter (instrument powering, in-set battery charging), 1 Li Battery, 1 EMAT Probe, 1 Probe Elevator, 1 Probe Spanner, 1 Linear Scanner, 1 Multi-oriented Scanner, 1 Heat-proof Handle, 1 Probe Cable (Ordinary Temperature), 1 Probe Cable (High Temperature), 1 AC Power Cable, 1 Screwdriver for locking the back cover of the battery container, 1 Leather Sheath (kitted with 1 leather sling & 1 grip belt), 1 Suitcase for packing all the things up and carrying on the move, 1 CD burned of ComApp and user manual., Spare Battery Charger (Optional),

- Main Export Market(s)

- Asia

About EMAT Ultrasonic Thickness Gage

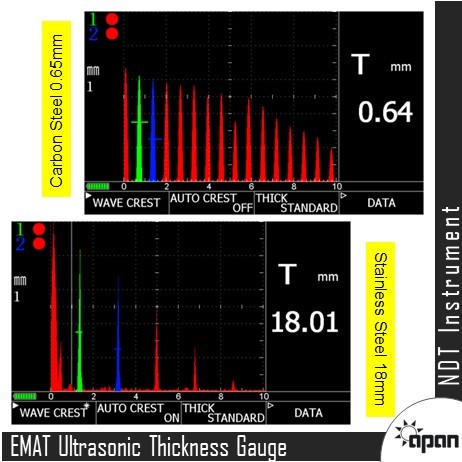

This is a portable electromagnetic ultrasonic abbr as EMAT thickness gauge to be used without couplant or direct contact on materials ofmetal or magnetism based on electromagneticacoustic transduction

The main difference of this technology is that the ultrasonic waveis generated directly in the tested object

The principle of the action of EMA transducers is based on theexcitation and reception of ultrasonic waves by induction on the surface of anelectrically conductive object of alternating and constant magnetic fields TheEMAT inductor through which a highfrequency current pulse flows creates aneddy current in the surface layer of the metal As a result of the combinedeffect of the eddy current and the polarizing field Lorentz forces arisewhich ensure the excitation of ultrasonic oscillations of the correspondingtype Depending on the design parameters of the inductor and the orientation ofthe polarizing field shear SH waves of radial or linear polarization an ovalor rectangular inductor are excited during the monitoring process

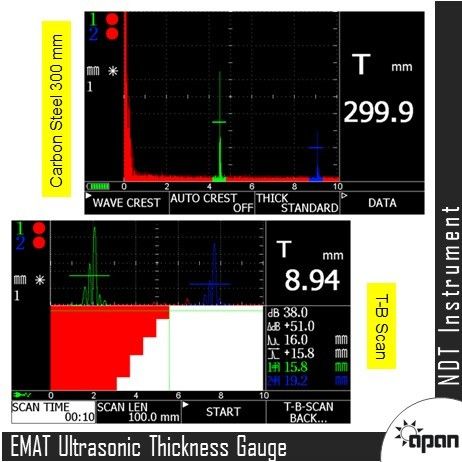

Due to naffectedness by surface of the object it can be appliedto those with rust oxide layer or coating like oil pipe or aircraft partssaving the effort to clear them off Angle shift of the probe has no effect onthe result with the available gauge range 2300mm and the precision up to 001mmThis instrument can also work on hot objects such as forged pieces radiatorsand heat exchangers assisted by necessary kittings supplied by the manufacturerTherere optional functionalities like BScan RS485 BUS networking GPRSwireless communicating and SMS for the users to realize their modern dreams onNDT instruments

Areas of Application

- Metallurgy

- Aerospace

- Pressure Vessel

- Thermal Circulation

- Shipbuilding

- Machinery

- Construction

- Power Generation

- Nuclear Power

- Refrigeration

Purposes

- To gauge thickness of metal ormagnetic objects with rough surface that might cause poor coupling for pureultrasonic transduction

- To get precise thickness dataof metal part beneath coated layer, such as rust, oxide or artificial coatingmaterial. Oil pipes, aircraft parts

- To work under special situation that theres air gap or some obstacle stuck between the transducerand the metal object.

- As an solution to thickness gauging on objects of high temperature without loss of data and damage to thetools (transducers & instrument) and the operator forged pieces, radiators, heat exchangers (up to 300 at-and-away: up to 600)

- to make the job of gauging go on under severely cold weather (lowest to -40)

EMAT Transducer

The is kitted with an EMAT probe (2MHZ but can be customized to different specification)that can induce eddy current as to generate ultrasonic wave on the surface of ametal or magnetic object by permanent magnet and electrified coil. Strongconstitution by solid casing and temp-insensitive element enables this transducerto function over harsh conditions like coarse-textured interface and extremeclimate (kitted with heat-proof probe cable).

Specification

|

Standard |

EN 12668-1 compliance |

|

Measuring range |

1.0 - 300.0mm |

|

Temperature range of work pieces |

-40-300 |

|

Display |

4.3 industrial-leveled TFT color LCD with 800 x 480 WVGA resolution |

|

Excitation Pulse Intensity |

350 Vpp |

|

Sampling Frequency / Bits |

160MHz/10Bit |

|

Bandwidth Range |

300kHz x 5MHz |

|

Rectification |

Positive half wave, negative half wave, full wave and RF |

|

Range Adjustment Step |

1mm (Transverse wave) |

|

Gain |

Total attenuation of 110dB, step as 0.1, 2.0 and 6.0 |

|

Distance from test object |

3mm |

|

Horizontal Linearity Error |

0.4% |

|

Dynamic Range |

30dB |

|

Excitation Mode |

permanent magnet |

|

Weigh |

1.0kg |

|

Power Supply |

Large-capacity lithium battery without memory effect, more than 8 hours |

Advanced EMAT Technology for Reliable Measurement

The gages Electromagnetic Acoustic Transducer (EMAT) enables precise, non-contact thickness measurement. Its particularly effective with ferromagnetic and conductive metalseven those with rough, corroded, or oxidized surfaces. This feature removes the need for couplants or significant surface preparation, ensuring both speed and accuracy across a broad range of industrial applications.

Robust Memory, Power, and Protection for Field Use

Equipped with a robust internal memory storing up to 2000 readings, the device is suitable for extended inspection cycles. The IP54-rated housing reliably shields the unit from dust and water, while the rechargeable lithium-ion battery provides up to 10 hours of continuous usage. Its durable design makes it ideal for demanding industrial or field environments in India.

User-Friendly Operation and Flexible Configuration

Operators benefit from manual and automatic control modes, supporting both single-point and continuous measuring techniques. Calibration can be performed via single or two-point modes to enhance accuracy. Adjustable test width and stroke, selectable frequencies, and various language supports cater to diverse inspection requirements and operator preferences.

FAQs of EMAT Ultrasonic Thickness Gage:

Q: How does the EMAT Ultrasonic Thickness Gage operate without contact or couplants?

A: The device employs an Electromagnetic Acoustic Transducer (EMAT) that generates ultrasonic waves directly within ferromagnetic and conductive metals. This non-contact approach eliminates the need for gels or liquids, making it efficient for measuring rough, oxidized, or coated surfaces.Q: What types of materials are compatible with this thickness gage?

A: The gage is engineered for ferromagnetic and conductive metals, including steel and various industrial alloys. Its EMAT technology enables accurate results even on challenging or corroded surfaces.Q: When is it beneficial to use this thickness gage in industrial settings?

A: This instrument excels during maintenance, inspection, and quality assurance processesparticularly when you need quick, repeatable, and non-destructive thickness measurements of metal structures, pipes, or fabricated components, even under harsh environmental conditions.Q: Where can the EMAT Thickness Gage be used most effectively?

A: Its IP54 protection and portable design make it suitable for use in industrial plants, laboratories, field sites, and during on-site inspections throughout India. It performs well in environments with high humidity (85% RH) and temperature extremes (-20C~+60C).Q: What is the process for calibrating the thickness gage?

A: Calibration can be performed using either a single-point or two-point method. This option allows users to optimize accuracy based on known material standards before commencing measurements.Q: How is data stored and transferred from the device?

A: Measured data, up to 2000 readings, are stored in the internal memory. Data transfer is facilitated by USB or RS232 interfaces, and the firmware can be updated via USB for enhanced functionality.Q: What are the main benefits of choosing this semi-automatic EMAT gage?

A: Key advantages include non-contact measurement, high accuracy (0.02 mm), rapid response time (1 second), suitability for rough surfaces, broad measuring range (0.8150 mm), and robust constructionsupporting reliable operation and data management in demanding work environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NDT Equipment Category

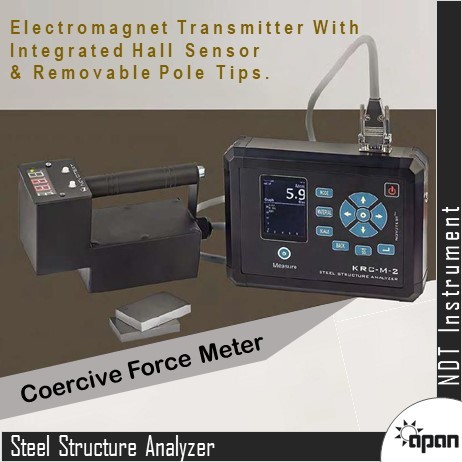

Steel Structure Analyzer

Measuring Range : 0 9999 units

Response Time : 2 seconds

Usage : Industrial / Laboratory

Test Range : 2 kN 300 kN

Automation Grade : SemiAutomatic

Power Supply : 220V / 50Hz

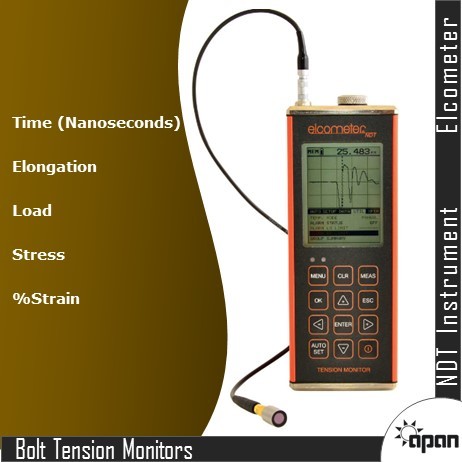

Bolt Tension Monitors

Measuring Range : 0100 kN

Response Time : <2 seconds

Usage : Bolt tension measurement

Test Range : 0100 kN

Automation Grade : Automatic

Power Supply : 220 V AC, 50 Hz

Flaw Detector Transducers

Measuring Range : 0.5 mm 500 mm (material dependent)

Response Time : < 10 ms

Usage : Nondestructive testing (NDT)

Test Range : 05000 mm (steel equivalent)

Automation Grade : Semiautomatic

Power Supply : AC 220V/50Hz

Precision Thickness Gauge

Measuring Range : 010 mm

Response Time : Instantaneous

Usage : Laboratory and Industrial

Test Range : 010 mm

Automation Grade : Manual

Power Supply : No Power Required

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry