Smart Ultrasonic Thickness Gauge

Smart Ultrasonic Thickness Gauge Specification

- Equipment Type

- Smart Ultrasonic Thickness Gauge

- Resolution

- 0.1 mm

- Application

- Non-destructive Thickness Measurement of Metals, Pipes, and Plates

- Automation Grade

- Manual

- Number of Specimens

- 1 per Operation

- Accuracy

- (1%H+0.1) mm

- Gas Pressure

- Ambient

- Humidity

- 85% RH

- Power Supply

- 2 x 1.5V AA Batteries

- Mounting Type

- Handheld

- Port Size

- Standard

- Temperature

- 0 ~ 40C

- Specimen Size

- Minimum 20 20 mm

- Operating Voltage

- 3V

- Response Time

- < 1 sec

- Display Type

- LCD Display

- Features

- Portable, Lightweight, High Precision, Auto Power Off

- Test Range

- 1.2 225.0 mm (in Steel)

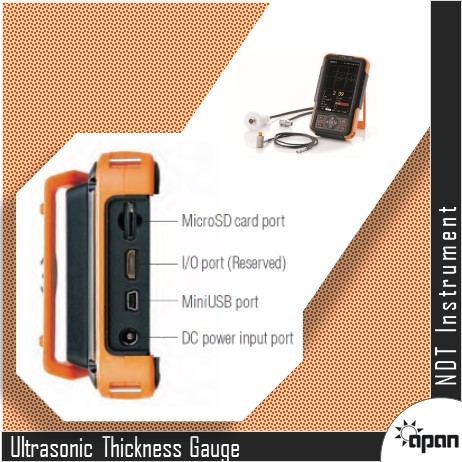

- Interface Type

- User Buttons

- Hardness

- Compatible with Various Metals

- Measuring Range

- 1.2 to 225 mm

- Max Height

- Standard

- Frequency

- 5 MHz

- Usage

- Pipe and Plate Thickness Monitoring

- Capacity

- Single Piece

- Machine Weight

- 300 g

- Test Speed

- 2 mm/sec

- Test Width

- Normal

- Test Stroke

- Standard

- Control Mode

- Manual

- Dimensions

- 150 74 32 mm

- Backlight Display

- Yes

- Low Battery Indication

- Yes

- Probe Type

- Standard 5 MHz Probe

- Minimum Pipe Diameter

- 20 mm 3.0 mm

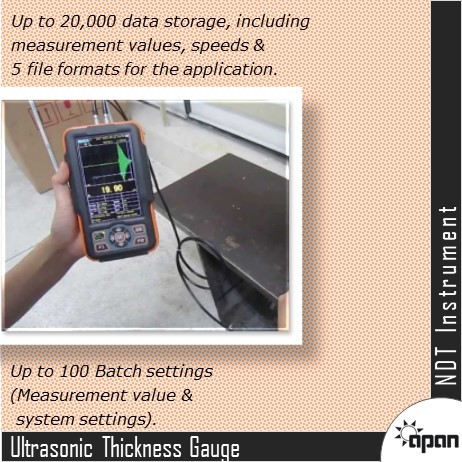

- Data Storage

- Up to 20 readings

- Operating Principle

- Ultrasonic Pulse-Echo Method

- Sound Velocity Range

- 1000 ~ 9999 m/s

- Protection Rating

- IP54

- Coupling Indicator

- Yes

- Operating Language

- English

- Calibration Method

- Auto and Manual Calibration

Smart Ultrasonic Thickness Gauge Trade Information

- Main Export Market(s)

- Asia

About Smart Ultrasonic Thickness Gauge

As an Authorized dealer we are engaged in providing the broad assortment of wide gamut of NDT InstrumentsThe latest Smart ultrasonic thickness gauge is to keep pace with the leading technology and the market requirements This is high end thickness gauge models which combine the latest techniques innovative design and complete inspection requirements It is suitable for a wide range of applications especially corrosion application

Small Size Powerful Functions

The latest ultrasonic thickness gauge to keep pace with the leading technology

and the market requirements This is high end thickness gauge models which combine the latest techniques innovative design and complete inspection requirements It is suitable for a wide range of applications especially corrosion application

Features

- Compatible with different kinds of probes

- Measurement range 05600mm

- Compact size and weighs only 06kg including battery

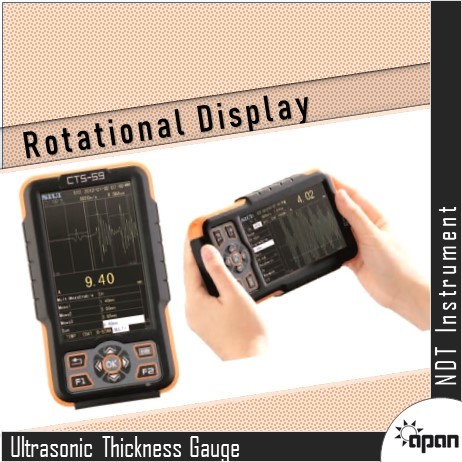

- 5 high resolution color TFTLCD monitor with highbrightness LED backlight visible under sunshine 800x480 pixels

- Auto search function can automatically adjust display delay display range gain and measurement gate based on the detected echo

- Normal RB1 transmission pulse to the first echo velocity measurement through coating measurement or echo to echo B1B2 or BmBn coating measurement functions available

- Onepoint Twopoints and Fast Zero point calibrations available

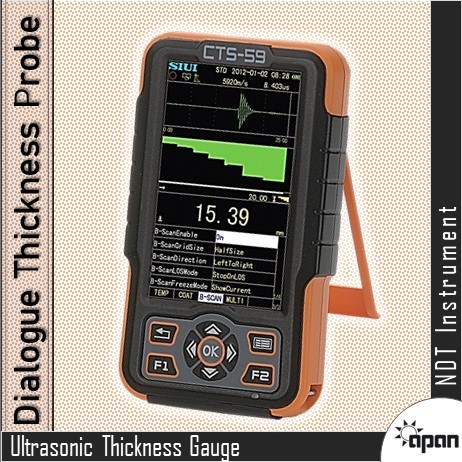

- Single and dual element probes for selection CTS59 can support dialogue thickness gauge probe to realize probe autorecognition function which can reduce display measurement data error

Smart Dialog probes

- Intelligent dialog probes are automatically identified by the corresponding

- instruments and ensure optimum settings as well as an improved test reliability

Data View Software

A Microsoft Windows based application is used to acquire create print and manage data on the Ultrasonic Thickness Gauge Measurement data will be displayed in color grid view mode for better data analysis

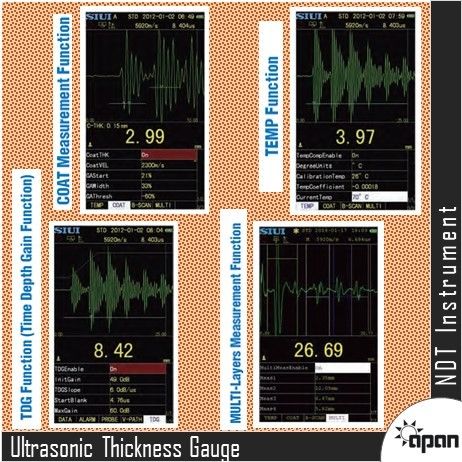

COAT Measurement Function

Under ThruCoating mode after setting the painting velocity throughcoating thickness and coating thickness can be displayed at the same time

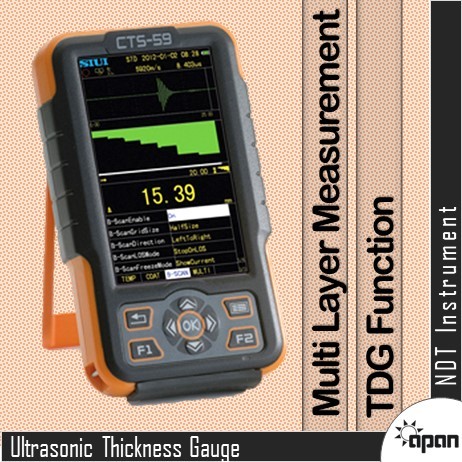

MultiLayers Measurement Function

For work piece with multilayer materials and tight bonding between each layer thickness measurement of each layer with known velocities as well as the total thickness can be displayed

VPATH Function

The system default sets a group of VPATH calibration curve for all compatible dual crystal probes Users can make a group of VPATH curve corresponding to the probes to be used

TEMP Function

When there is temperature difference between the calibration block and the detected work piece it can be used for temperature compensation

TDG Function Time Depth Gain Function

It can be used for compensating wave amplitude loss caused by transmitting sound path

High Precision Non-Destructive Testing

Engineered for accurate thickness measurement, the Smart Ultrasonic Thickness Gauge utilizes ultrasonic pulse-echo technology to assess metals, pipes, and plates without causing damage. Whether working with new materials or conducting inspections on installed structures, this instrument provides fast, reliable results with an accuracy of (1%H+0.1) mm and a resolution of 0.1 mm.

Built for Industrial Environments

With its IP54 protection rating and robust build, this thickness gauge delivers consistent performance even in demanding conditions. A large LCD with backlight ensures legible readings in low-light areas, while low battery and coupling indicators enhance operational reliability. It is perfectly suited for workshop, factory, and onsite use across diverse industrial sectors.

Intuitive Operation and Versatile Calibration

Users benefit from both manual and automatic calibration options, streamlining setup for different materials and ensuring measurement accuracy. The device operates in English and features straightforward user buttons, promoting ease of use even for first-time operators. Storing up to 20 readings facilitates convenient data tracking for quality assurance and reporting.

FAQs of Smart Ultrasonic Thickness Gauge:

Q: How does the Smart Ultrasonic Thickness Gauge work for thickness measurement?

A: The device uses the ultrasonic pulse-echo method, emitting sound waves through a probe into the material. It measures the time taken for the echo to return, calculating thickness based on the speed of sound through the tested metal. This allows for non-destructive and highly accurate measurement.Q: What types of materials can be measured using this ultrasonic gauge?

A: The gauge is designed mainly for metals, including pipes and plates, with a measuring range of 1.2 to 225 mm in steel. It accommodates various metals provided the material supports ultrasonic testing.Q: When should I use auto versus manual calibration?

A: Auto calibration is recommended for quick setup when testing common materials with standard properties, while manual calibration is best for ensuring maximum accuracy, especially when measuring materials with unique characteristics or when precision is critical.Q: Where can this thickness gauge be effectively used?

A: Thanks to its IP54 rating and portable design, the device can be used in factories, workshops, production sites, and field locations. It performs reliably in environments with ambient gas pressure, humidity up to 85%, and temperatures ranging from 0 to 40C.Q: What is the process for storing and recalling measurements?

A: The gauge can store up to 20 readings internally. After completing a measurement, simply press the designated button to save the value. Stored data can be recalled as needed for reporting or analysis purposes.Q: How is the Smart Ultrasonic Thickness Gauge powered, and what is its battery life?

A: The device runs on two 1.5V AA batteries, with features such as low battery indication and auto power-off to conserve energy. Under typical use, the device provides extended at-site operation before requiring battery replacement.Q: What are the benefits of using this ultrasonic gauge compared to traditional methods?

A: Compared to traditional measurement techniques, this gauge offers rapid, non-destructive, and highly accurate thickness readings. Its portability, intuitive controls, data storage, and reliable performance in industrial conditions make it ideal for routine inspection and maintenance tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NDT Equipment Category

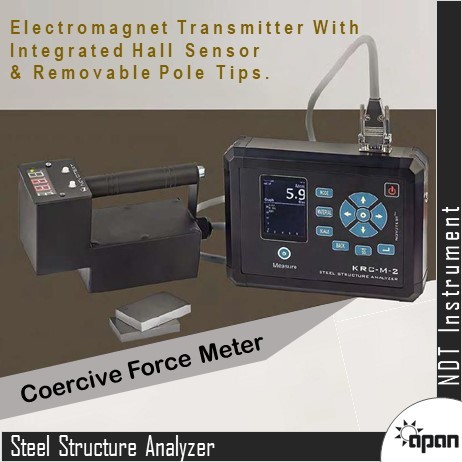

Steel Structure Analyzer

Temperature : 5C to 40C

Power Supply : 220V / 50Hz

Mounting Type : Benchtop

Humidity : 10% 85% RH

Automation Grade : SemiAutomatic

Application : Steel Structure Testing, Quality Assurance, Research & Development

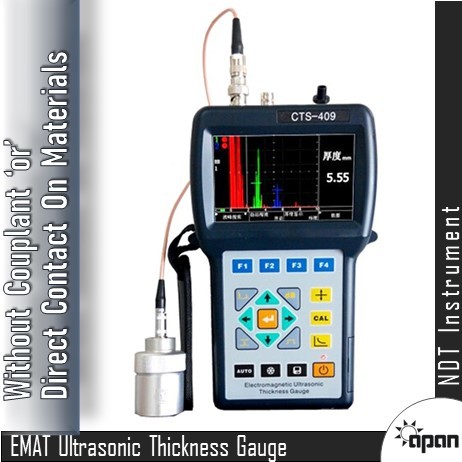

EMAT Ultrasonic Thickness Gage

Temperature : 20C~+60C

Power Supply : AC 220V, 50/60Hz

Mounting Type : Handheld/Portable

Humidity : 85% RH

Automation Grade : Semiautomatic

Application : Nondestructive thickness measurement of conductive materials

Spark Tester

Temperature : 0C to 50C

Power Supply : 230V AC, 50 Hz

Mounting Type : Desktop

Humidity : Up to 85% RH

Automation Grade : Manual

Application : Testing insulation of wires and cables

Precision Ultrasonic Thickness Gage

Temperature : 10C to 60C

Power Supply : 2 x 1.5V AA batteries

Mounting Type : Handheld

Humidity : 85% RH

Automation Grade : Manual

Application : Thickness measurement of metals, glass, plastics, ceramics, and other ultrasonic conductors

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry