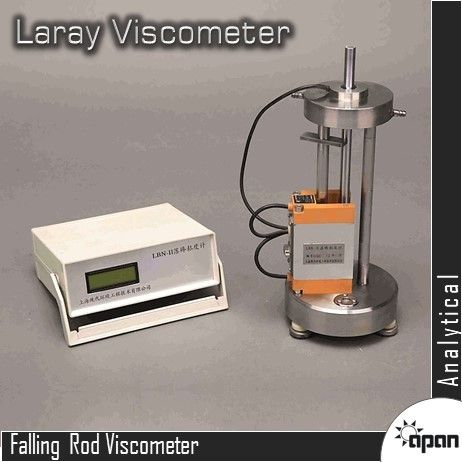

Falling Rod Viscometer

Falling Rod Viscometer Specification

- Humidity

- 80% RH

- Interface Type

- RS232, USB

- Port Size

- Standard sample insertion port, customizable

- Specimen Size

- Standard tube: 25 mm x 280 mm

- Resolution

- 0.1 cP

- Automation Grade

- Semi-automatic / Automatic

- Features

- Corrosion-resistant, sample tube visibility, robust construction

- Response Time

- 2 seconds

- Application

- Measurement of viscosity in liquids and semi-liquids

- Max Height

- 350 mm (with stand)

- Test Range

- 5 20000 cP (centipoise)

- Measuring Range

- 5 20000 cP

- Hardness

- N/A (Not applicable)

- Power Supply

- 220V AC, 50Hz

- Operating Voltage

- 220V AC

- Display Type

- Digital LED

- Equipment Type

- Falling Rod Viscometer

- Number of Specimens

- Single rod test configuration

- Mounting Type

- Bench-top

- Accuracy

- 1% of full scale

- Frequency

- 50Hz

- Temperature

- Room temperature (15C 35C)

- Usage

- Laboratory viscosity measurement

- Capacity

- For sample volumes up to 100 mL

- Machine Weight

- 18 kg

- Test Speed

- Variable (adjustable)

- Test Width

- Standard, adaptable to rod length

- Test Stroke

- Up to 250 mm

- Control Mode

- Manual / Automatic (Digital) options

Falling Rod Viscometer Trade Information

- Main Export Market(s)

- Asia

About Falling Rod Viscometer

As a Authorized dealer we are engaged in providing the broad assortment of wide gamut of Analytical Laboratory Instruments

Falling Rod Viscometer Laray Viscometer is an instrument applicable to determinethe rheological properties apparent viscosity pseudoyield value shortness etc of NonNewtonian liquids viscosityincreases with shear rate Larya Viscometer designed and produced by ourcompany is in accordance with the specification of ASTM D 404010 and ISO126441996E Graphic technology Determination of rheological properties of pasteinks and vehicles by the Falling Rod Viscometer Its principle measuring falltimes by loading the rod with different load weights pass the gap which isfilled with the test fluid By applying linear regression methods bymeans of suitable flow model Casson model Bingham model or Power Law model to obtain apparent viscosity yield value shortnessratio of sample

Specification

Input voltage 220V 50Hz

Range of apparent viscosity 2200Pas

Dimensions of the falling rod 12x300mm

Weight of the falling rod 132g

ets of load weights total 4075g 2550100200200500100010001000g

Overall dimensions 140mm x 140mm x 300mm length by width by height

Weight including instrumen tweight box controller 18kg

Test procedure

Prior to usethe test sample about 5g shall be kneaded by a spatula and equilibrated totest temperature The sample shall be homogeneous and not contain any coarseparticles An amount of the test sample sufficient to coat the rod and apertureis applied to the lower part of the rod

The bottom of the rod is inserted into the aperture of guide bush andslightly fall on the turntable the sample is distributed uniformly around thegap the gap is filled with the test fluid which is sheared when the rod fallsby using fingertip lift the bottom of the rod 20mm then fall on theturntable

Load weights to be loaded on top of the rod remove a turntable to letfalling rod fall the rod and the aperture are wetted by the liquid Make surethat photoswitch temperature sensor are working normally temperatureindicator display starting temperature when starting falling time indicatorstarts to display seconds temperature indicator display finishing temperaturewhen finishing falling time indicator display actual fall time temperatureresume to display actual temperature of guide bush after pulling up the rodtime automatically clear

Avoid anyscoring operation for the rod the metal spatula should not be allowedoperation for the rod Dont do falling operation under the condition of notest sample After finishing falling the rod is lightly pulled up and restedon the support After each run the rod is scraped with the spatula and theliquid which was scraped off is reapplied on the lower part of the rod the aperture of guide bush

The proper sets of load weights is selected according to the expectedresults The fall time with the heaviest load weight should normally be in therange from 4s to 10s ASTM D404005 recommend 12s Series of load weights arecombined to sets Sets of load weights with the following masses should beused Unit g

A 5000 4000 3000 2000 1000

B 3000 2000 1500 500

C 1500 1000 800 500

D 800 600 400 200

E 400 300 200 100

F 200 100 50 0

The sample is tested with the heaviest load weight at the beginning of thetests load weighs in descending order Fall time during the test with theheaviest load weight varies less than 05s the sample is tested with theselected series of load weights in descending order The fall time shall notexceed 60s After each run the rod is scraped with the spatula and the liquidwhich was scraped off is reapplied on the lower part of the rod During thetest additional liquid shall not be added The sample is tested with each loadweight for three times By loading the rod with different load weights recordthe fall time every time correct to 001s and temperature of guide bushduring measurement correct to 01

Operationshall be done quickly and cant be interrupted the whole operation shall befinished within 510 minutes Many printing ink and vehicles have strongvolatile solvent only if strictly control actual exposition time otherwisevolatile loss cause large deviation of test result during operation If foundseveral continuous falling with the same load weight fall time could belonger it indicates that obvious volatile loss exists

Viscosity is strongly temperature dependent therefore the temperature shallbe controlled and monitored Principally if the test temperature varies fromreference temperature 25 by more than 02 before the runs the thermostatic equipment shall be reset if thetemperature during the test varies more than 1 the test shall be repeated

After the test the instrument shall be cleaned immediately with a lintfreewiper and a suitable solvent especially the rod guide bush

ISO12644

Graphic technology Determination of rheological properties of paste inks and vehicles by the falling rod viscometer This International Standard specifies the procedure for determining theviscosity and yield value of paste inks and vehicles which are unreactive under normal room conditions It is applicable to inks in the apparent viscosityrange of 2 Pa s to 200 Pa s

ASTM D 404010

Standard Test Method for Rheological Properties of Paste Printing and Vehicles by the FallingRod Viscometer Apparent viscosity at the relatively high shear rate of 2500 does not completely define the rheological properties of printing inks but is useful in the practical control of ink viscosity during production and the specification acceptance between supplier and purchaser

The slope of the power law plot is the preferred measure of nonNew tonianism The yield value which is obtained by extrapolation of highshear measurements to a shear rate approaching zero does not conform to the definition of the true yield stress The yield value and other low shear parameters are also subject to a high degree of variabilit

High-Precision Viscosity Measurement

Achieve highly accurate viscosity readings with this Falling Rod Viscometer, offering 1% of full-scale accuracy and a broad measurement range of 520,000 cP. Its advanced digital timer, fast response time (2 seconds), and easy-to-read LED display streamline laboratory workflows.

Durability and Safety in Every Test

Constructed with a robust stainless steel rod and borosilicate glass tube, this viscometer is built for long-lasting performance in harsh laboratory environments. Overload and short-circuit protections safeguard both the operator and the instrument during operation.

Customizable and User-Friendly Operation

Switch effortlessly between manual and automatic digital control modes to adapt to your workflow. Adjustable test speeds, variable test stroke up to 250 mm, and optional temperature control provide versatility for a range of liquid or semi-liquid samples.

FAQs of Falling Rod Viscometer:

Q: How does the Falling Rod Viscometer measure viscosity?

A: The viscometer measures viscosity by recording the time it takes for a stainless steel rod to fall through a sample contained in a borosilicate glass tube. The microprocessor-based digital timer precisely captures the movement, allowing the digital system to calculate viscosity based on the fall time and rod dynamics.Q: What types of samples can be tested with this viscometer?

A: This equipment is suitable for testing a variety of liquids and semi-liquids, with a measurement range of 5 to 20,000 cP. The corrosion-resistant materials make it compatible with many chemicals commonly encountered in laboratory and industrial settings.Q: When should optional temperature control be used?

A: Whenever sample viscosity is sensitive to temperature variations or when strict temperature consistency is required for accurate results, the optional external bath integration should be employed. It maintains uniform sample temperature during testing.Q: Where can the viscometer be used?

A: Designed as a bench-top device, the viscometer is ideal for laboratory use in research institutions, quality control departments, and industrial testing labs. Compact dimensions and robust construction enable easy placement on lab benches.Q: What is the process for starting a test with this viscometer?

A: Insert the sample into the borosilicate glass tube (up to 100 mL), select manual or automatic mode, and adjust test parameters as needed. Once set, initiate the test; the rod will fall and the digital timer records the event, displaying results instantly on the LED screen.Q: What are the benefits of using this viscometer over others?

A: This viscometer offers superior accuracy (1% of full scale), rapid response (2 seconds), and flexibility with manual/automatic controls. Its construction resists corrosion and ensures clear sample visibility, while safety features provide reliable operation in diverse laboratory settings.Q: How is the data output handled for recorded test results?

A: The device features RS232 and USB interfaces, allowing easy transfer of recorded viscosity data to computers or laboratory information management systems for further analysis, documentation, or reporting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Analytical Lab and Field Category

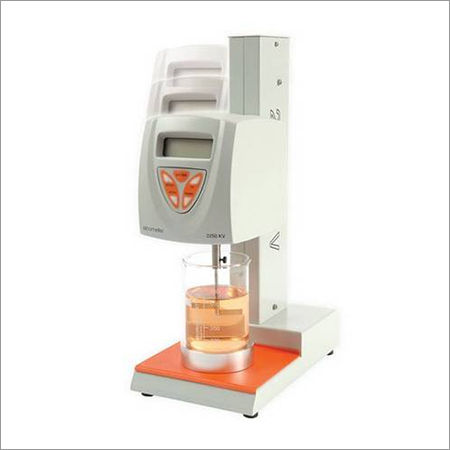

Krebs Viscometer

Accuracy : 1% of full scale

Machine Weight : 5.5 kg (approx.)

Usage : Laboratory, quality control, R&D

Temperature : Working 535C

Number of Specimens : Single sample measurement

Mounting Type : Benchtop

Rotational Viscometer

Accuracy : 1.0% of full scale

Machine Weight : 6.8 kg

Usage : Laboratory, industrial, quality assurance

Temperature : 5C35C (operating range)

Number of Specimens : 1 per test cycle

Mounting Type : Benchtop

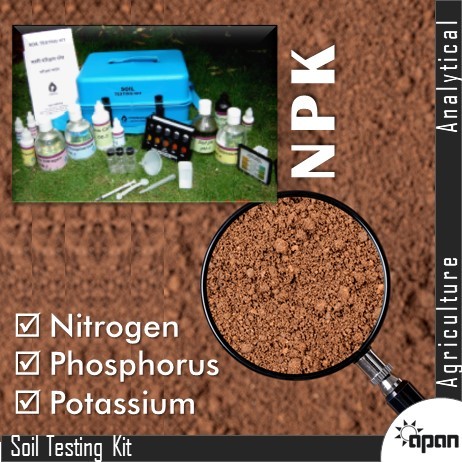

Soil Testing Kit - Secondary

Accuracy : Based on color chart and visual comparison

Machine Weight : 2.7 kg

Usage : For field and laboratory soil secondary nutrient analysis

Temperature : 10C to 40C (operational)

Number of Specimens : Can test 50 samples per kit (approx)

Mounting Type : Portable/tabletop

Digital Balance

Accuracy : 0.01 g

Machine Weight : Approx. 350 g

Usage : Precise Weighing

Temperature : 0C ~ 40C

Number of Specimens : 1

Mounting Type : Bench Top

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry