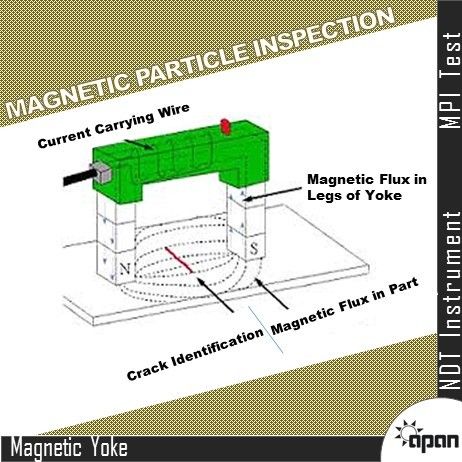

Magnetic Yoke

Magnetic Yoke Specification

- Features

- Portable, Rugged, Easy operation

- Temperature

- 0C to 50C

- Frequency

- 50 Hz

- Equipment Type

- Magnetic Yoke

- Specimen Size

- Various depending on geometry

- Mounting Type

- Handheld

- Operating Voltage

- 230V AC

- Power Supply

- 230V AC, 50 Hz

- Response Time

- Immediate

- Accuracy

- High sensitivity to small cracks

- Automation Grade

- Manual

- Humidity

- Up to 85% RH

- Measuring Range

- Depends on flaw size and specimen

- Number of Specimens

- Single test at a time

- Interface Type

- Manual

- Test Range

- Detects surface and subsurface cracks

- Application

- Magnetic particle flaw detection

- Usage

- Industrial Non-Destructive Testing (NDT)

- Capacity

- 10 kgs

- Machine Weight

- Approx. 3 kg

- Test Speed

- Manual operation

- Test Width

- Up to 125 mm

- Control Mode

- Handheld

- Magnetic Field Strength

- Minimum 10 kg (22 lbs) lifting power

- Safety Standard

- Meets international NDT safety norms

- Color

- Typically Black or Grey

- Mounting Type

- Handheld

- Leg Spacing

- Adjustable from 0-200 mm

- Compliance

- IS: 6410, ASTM E709

- Service

- On-site/Off-site support available

- Frequency

- 50/60 Hz

- Pole Pieces

- Replaceable / Swiveling legs

- Housing Material

- Impact resistant polymer or metal

- Features

- Lightweight, Portable, Ergonomically designed, Easy grip handle, Durable construction

- Cord Length

- 2-3 meters

- Automation Grade

- Manual

- Usage

- Non-Destructive Testing

Magnetic Yoke Trade Information

- Main Export Market(s)

- Asia

About Magnetic Yoke

As an Authorized dealer we are engaged in providing the broad assortment of "NDT Equipments" for wide range of application..

- Used for the detecting of Oil field, Boat making, Car making, Coal mine, Machine, Medicine, Airplane making and internal combustion engine parts etc.

- Also detecting for the surface defecting caused by Forge, Quenching,Welding,Fatigue etc.

- Type of power supply

- Alternating current

- Alternating current-direct current

- Input votage

- 220V ±10%,50-60Hz

- alternating current 2A, direct current1.8A

- Probe limits

- 20-200mm

- Type A specimens show clear

- Elevating weight

- alternating current(plane)8kg;direct current more than 30kg

- 2 minutes to start up and 2 minutes to stop

- electric cable 5.5m

- -10-50 ºC

- 190 x 248 x 546mm

- 2.9kg

Portable and Durable Design

Built for harsh industrial environments, this magnetic yoke combines portability with durability. Weighing approximately 3 kg, it is easy to handle during prolonged inspections, while the impact-resistant polymer or metal housing ensures reliable performance even under rough treatment and challenging conditions.

Flexible and Easy Operation

Featuring adjustable leg spacing from 0 to 200 mm and replaceable, swiveling pole pieces, this yoke suits varied specimen geometries. Its manual interface allows for simple operation, making it ideal for on-site magnetic particle flaw detection. A cord length of 2-3 meters provides freedom of movement while conducting tests.

High Sensitivity and Compliance

Engineered to international NDT safety norms, the yoke complies with IS: 6410 and ASTM E709 standards. It boasts high sensitivity, effectively identifying minute surface and subsurface cracks quickly, thus ensuring the integrity and safety of critical industrial components. Immediate response time enhances workflow and productivity.

FAQs of Magnetic Yoke:

Q: How is the magnetic yoke used in industrial non-destructive testing (NDT)?

A: The magnetic yoke is handheld and placed directly onto the material being inspected. By manually operating the device, an AC magnetic field is generated between the legs, enabling detection of surface and subsurface cracks when magnetic particles are applied.Q: What types of flaws can the magnetic yoke detect?

A: This yoke is highly sensitive and capable of identifying both surface and subsurface cracks in ferromagnetic materials, making it ideal for quality assurance in industrial settings where integrity is critical.Q: When should a portable magnetic yoke be selected over other NDT methods?

A: A portable magnetic yoke is recommended when inspecting large or irregularly shaped components on-site, requiring flexibility, quick setup, and immediate flaw detection, especially in applications where power sources or space are limited.Q: Where can the magnetic yoke be deployed for inspection?

A: Due to its rugged, impact-resistant housing and compact design, the magnetic yoke can be deployed in diverse industrial environments, including manufacturing plants, construction sites, and maintenance workshops.Q: What is the process for adjusting the yoke for specimens of different sizes?

A: Simply adjust the swiveling, replaceable legs to accommodate various geometries and test widths up to 125 mm. The legs can be spaced from 0 up to 200 mm, ensuring stable contact and optimal magnetic field application.Q: How does regular use of this equipment benefit industrial users?

A: Regular inspections with the magnetic yoke help ensure product quality and safety by providing early detection of cracks, reducing downtime, and helping to prevent costly failures in critical assemblies.Q: Does the magnetic yoke meet safety and compliance standards for NDT equipment?

A: Yes, the device fully adheres to IS: 6410 and ASTM E709 standards and meets international NDT safety requirements, ensuring trustworthy and compliant flaw detection for industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NDT Equipment Category

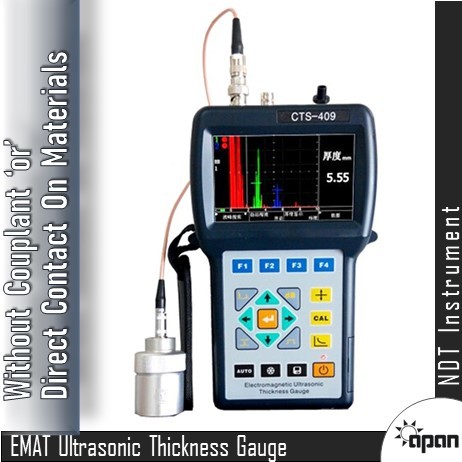

EMAT Ultrasonic Thickness Gage

Equipment Type : EMAT Ultrasonic Thickness Gage

Machine Weight : 2.7 kg

Temperature : 20C~+60C

Features : Noncontact measurement, high penetration, suitable for rough and oxidized surfaces

Frequency : 2.5 MHz/5 MHz (selectable)

Display Type : Digital LCD

Spark Tester

Equipment Type : Spark Tester

Machine Weight : Approximately 8 kg

Temperature : 0C to 50C

Features : Portable, Easy to operate, Overcurrent protection, Audible and visual alarm

Frequency : 50 Hz

Display Type : LED Digital Display

Precision Ultrasonic Thickness Gage

Equipment Type : Precision Ultrasonic Thickness Gage

Machine Weight : Approx. 250 g

Temperature : 10C to 60C

Features : Auto calibration, Low battery indication, Metric/Imperial unit switch, Backlit display

Frequency : 5 MHz (standard).

Display Type : LCD digital display (backlit)

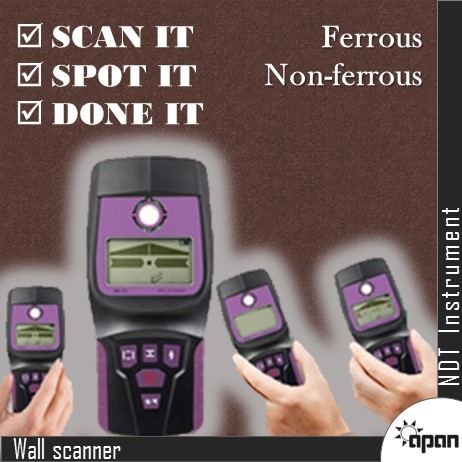

Wall Scanner

Equipment Type : Wall Scanner

Machine Weight : 0.5 kg

Temperature : 10C to 50C

Features : Live wire detection, autocalibration, ergonomic grip

Frequency : 5060 Hz

Display Type : Backlit LCD display

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry