Online Optical Density Monitor

Online Optical Density Monitor Specification

- Features

- Real-time monitoring, Auto-Calibration, In-line Installation, Low Maintenance

- Number of Specimens

- Single channel

- Port Size

- 1/2 inch (standard)

- Frequency

- 50 Hz

- Interface Type

- RS232/Analog Output

- Automation Grade

- Automatic

- Temperature

- 5C to 45C

- Operating Voltage

- 230V AC

- Accuracy

- 0.01 OD

- Display Type

- Digital (LCD)

- Application

- Continuous monitoring of cell growth, fermentation and microbial processes

- Equipment Type

- Online Optical Density Monitor

- Resolution

- 0.001 OD

- Test Range

- 0.0 to 3.0 OD

- Measuring Range

- 0.0 3.0 OD

- Response Time

- Less than 2 Seconds

- Mounting Type

- Inline, Pipe Mount

- Power Supply

- 230V AC, 50Hz

- Humidity

- 10% to 90% RH (non-condensing)

- Usage

- Industrial/Laboratory

- Machine Weight

- Approx. 3 kg

- Control Mode

- Digital Microcontroller Based

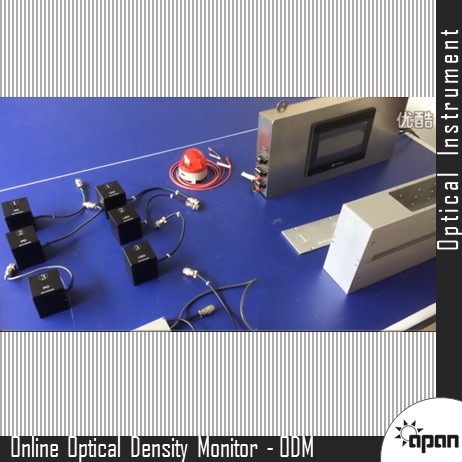

About Online Optical Density Monitor

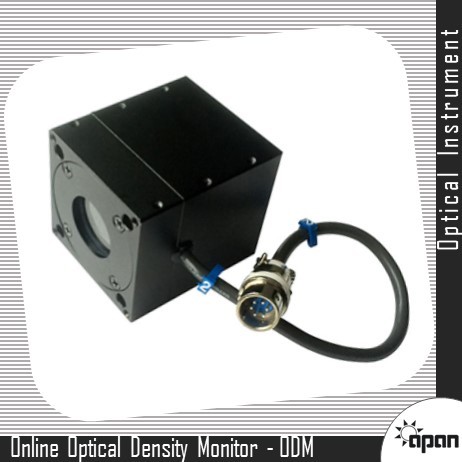

Online Optical Density Monitoris a non-contact online thickness tester for coating aluminized film, use the principle of optical transmittance to monitor the process of vacuum coating machine and the production line of glass, has two kinds of methods to display: transmittance and optical density.

The material of transmittance (optical density) and a certain proportion relationship with material of coating thickness. So by monitoring materials of optical transmittance (optical density) to achieve the uniformity of monitoring materials, the purpose of the coating thickness. As long as it is light through the material, can be monitored by monitoring the light transmittance product quality. Such as winding vacuum coating, coating, glass/film production line and so on.

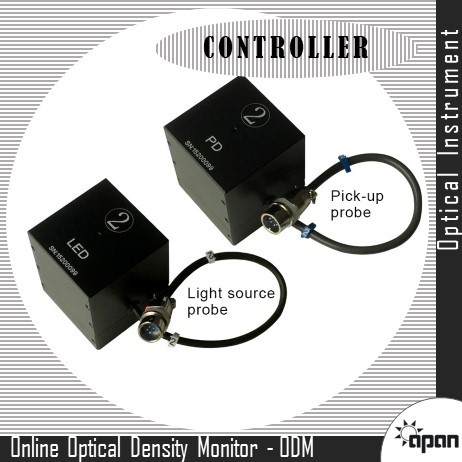

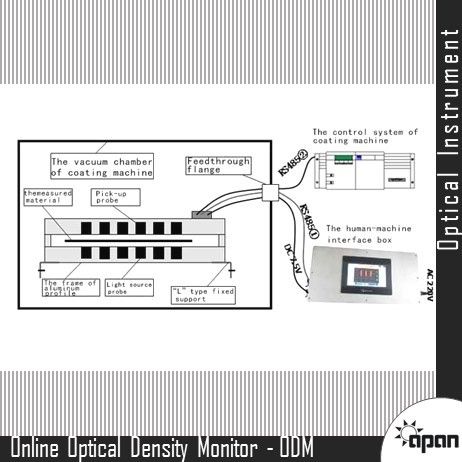

System is divided into 3 parts:

- Detection systems : Includes the source, receiver, controller and aluminum bracket;

- Human-computer interaction devices : 7 inch LCD MMI, display the transmittance and optical density data of every test points.

- Computer real-time monitoring system(Optional) : Data record, analysis, reporting, and other functions.

Due to the measured sample of this customer is more special, the card slot of our conventional glass transmittance on-line monitoring device is 20mm wide, can not meet customer needs. So we customized a flexible program, the test points, controllers and human-machine display interface will be provided by our company to test , collect, output and display dates. As for the bracket part,it will be customized according to the customers requirements. For this situation, the users will take the installation problem into account because my company doesnt provide the whole set of glass transmittance on-line monitoring device, , so I would like to introduce some details that we have considered for our customers.

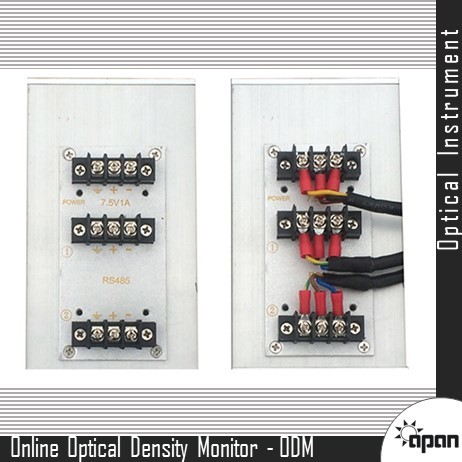

This instrument provides dual RS485 communication interface, the standard MODBUS communication protocol, convenient for communications among LC, single-chip computer, MMI, kingview and computer. Coating machine can read directly optical density data of the equipment to realize the automatic control (closed-loop control).

Parameter:

- Wavelength: according to the customers need to choose, there are following option

- Infrared : 850nm(the default option, strong anti-interference ability), Visible light : 380nm-760nm(white light), Green light : 530nm

- Accuracy : 1%

- Resolution : 0.005%

- Density measuring range : 0.00 -5.00 OD

- Density resolution : 0.01 for 0.00 - 3.00 OD, 0.05 for 3.00 - 5.00 OD

- The maximum measured points : 36

- Distance between adjacent probe head:70mm

- Distance between the sending and receiving probe: 20mm

- Temperature range:-20C +70C

- Data refresh cycle:300ms

- Size:100mm*230mm(W*H) Length according to customer requirements

- The number of flange electrode: 6(Not deserve a computer monitor) , 9(Deserve a computer monitor)

- Power supply:220V AC/50Hz

- Communication:dual RS485

Reliable Real-Time Cell Monitoring

This monitor facilitates uninterrupted, precise measurement of cell density, aiding optimization of fermentation and microbial processes. Its LED photodiode technology and auto/manual calibration deliver accuracy within 0.01 OD and a resolution of 0.001 OD, ensuring dependable data for various research and production scenarios.

Durable Build and Flexible Installation

Constructed with stainless steel and borosilicate glass, the probe withstands demanding laboratory and industrial settings. The inline/pipe mount design, standard 2-meter extendable cable, and IP65 protection enable versatile, safe installation for a wide range of applications and environments.

Smart Control and User-Friendly Interface

The unit utilizes a digital microcontroller for seamless operation and features a clear LCD display for instant readings. Its output options (analog and RS232) allow integration with control systems, while auto-calibration minimizes user intervention and maximizes measurement reliability.

FAQs of Online Optical Density Monitor:

Q: How is the Online Optical Density Monitor calibrated for accurate measurements?

A: Calibration can be performed either automatically or manually using standard solutions. The built-in digital microcontroller guides users through the process, ensuring precise readings within the measurement range of 0.0 to 3.0 OD.Q: What environments are suitable for installing this monitor?

A: The device is designed for both industrial and laboratory environments with a humidity range of 10% to 90% RH (non-condensing) and operating temperature from 5C to 45C. Its stainless steel and borosilicate glass build and IP65 protection enhance reliability in various settings.Q: When should real-time monitoring be utilized with this equipment?

A: Real-time optical density monitoring is most valuable during ongoing fermentation and microbial processes, allowing users to promptly detect and adjust for changes in cell growth and ensure process consistency.Q: Where can this monitor be mounted for optimal performance?

A: This unit is intended for inline or pipe mounting on sample lines with a standard port size of 1/2 inch. The design enables direct integration into existing flow systems with up to 10 L/h sample rate capability.Q: What are the main benefits of using the LED photodiode sensor at 600 nm wavelength?

A: The standard 600 nm wavelength is ideal for accurately assessing cell density, providing consistent sensitivity and minimal interference from solution components commonly found in microbial and cell growth studies.Q: How does the auto-calibration feature enhance operational efficiency?

A: Auto-calibration reduces manual intervention by automatically adjusting baseline measurements using reference solutions. This ensures both time savings and improved measurement reliability during continuous operation.Q: What is the process for using and reading data from the monitor?

A: After installation, the monitor measures optical density in real-time. Data is displayed on its LCD screen and can be output via analog (420 mA) or RS232 for integration with laboratory software or process control systems, facilitating easy recording and analysis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Optical Instrument Category

Chromatic Meter

Power Supply : 220V AC, 50Hz

Control Mode : Digital Control

Usage : Laboratory, Textile Industry

Resolution : 0.01 Unit

Specimen Size : 38 x 70 mm

Measuring Range : 0100

Powder Whiteness Meter

Power Supply : AC 220V, 50 Hz

Control Mode : Automatic

Usage : Whiteness measurement in powder technology

Resolution : 0.1

Specimen Size : 25 mm diameter cup, 10 mm thickness

Measuring Range : 0120

Digital Colorimeter

Power Supply : 220V AC, 50 Hz

Control Mode : Digital Microprocessor

Usage : Analytical laboratory, research, industrial QC

Resolution : 0.01 Abs

Specimen Size : Min. 15 mm x 15 mm, Max. 30 mm x 30 mm

Measuring Range : 400700 nm (Visible Range)

Novo Curve Glossmeter

Power Supply : 2 x AA Batteries

Control Mode : Manual

Usage : Nondestructive gloss measurement

Resolution : 0.1 GU

Specimen Size : Minimum radius: 5mm (concave and convex); Max curvature: 40mm

Measuring Range : 0 2000 Gloss Units

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry