Paint Inspection Gauge

Paint Inspection Gauge Specification

- Response Time

- Instantaneous

- Features

- Lightweight, Portable, Precise

- Mounting Type

- Handheld

- Measuring Range

- 0 - 2 mm

- Automation Grade

- Manual

- Temperature

- 5C to 50C operating

- Number of Specimens

- Single use per test

- Hardness

- Standard tip

- Application

- Coating and paint thickness measurement

- Equipment Type

- Paint Inspection Gauge

- Specimen Size

- Minimum 20 mm wide area

- Test Range

- Up to 2 mm coating thickness

- Humidity

- Up to 85% RH non-condensing

- Accuracy

- 0.01 mm

- Interface Type

- Manual

- Resolution

- 0.01 mm

- Display Type

- Dial gauge analog

- Usage

- Coating thickness inspection

- Capacity

- Standard

- Machine Weight

- 220 g

- Test Speed

- Manual operation

- Test Width

- Up to 20 mm

- Control Mode

- Manual

About Paint Inspection Gauge

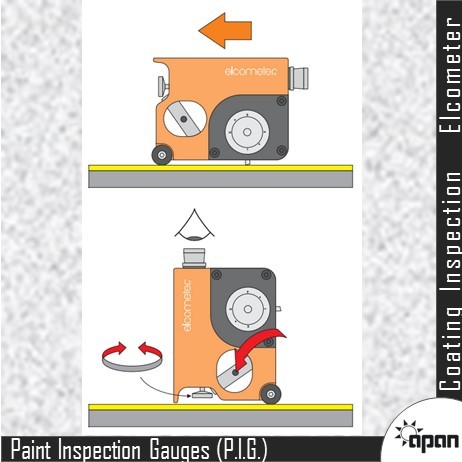

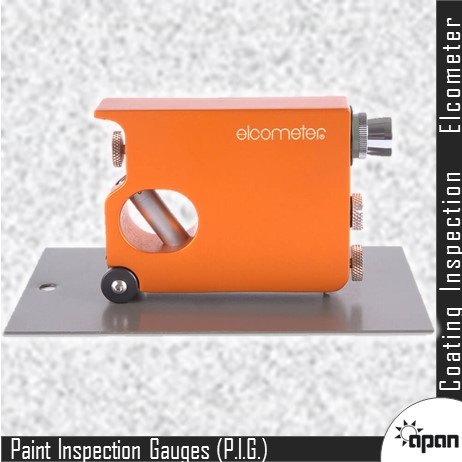

As an Authorized dealer we are supplying Elcometer, UK make Coating Inspection Equipment. The Elcometer 121/4 P.I.G. is a hand-held gauge that offers a quick, versatile method of coating examination and measurement in a portable, easy-to-use format. The gauge is available in two versions, Standard and Top:

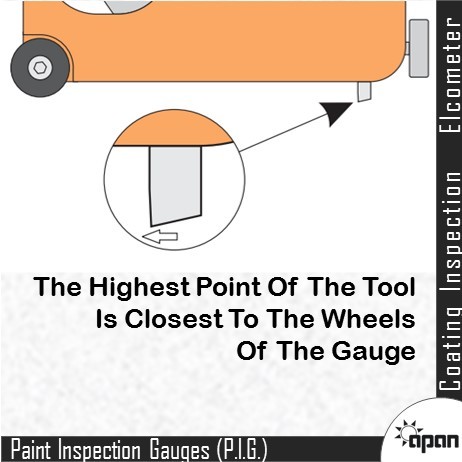

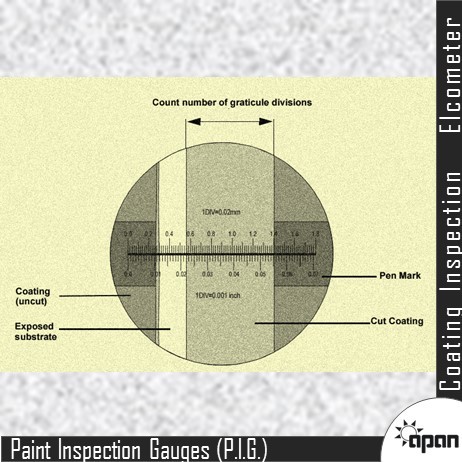

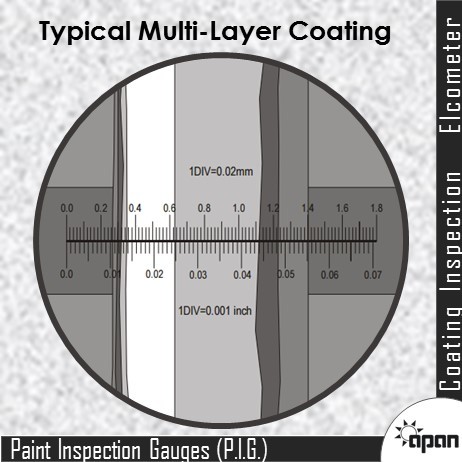

Destructive determination of dry film thickness of all types of single- or multi-coat systems using the wedge cut method as well as microscopic assessment in order to detect substrate and application defects

- Standard gauges can be used for microscopic coating examination and destructive measurement of coating thickness.

- Top gauges have the same functionality as standard gauges and can also be used for cross hatch adhesion testing using optional tools.

Both P.I.G. models are supplied with illuminated integrated graticule microscopes.

The Paint Inspection Gauge Top model has an internal carousel allowing each of the three cutters to be selected easily together with a cross hatch adhesion tester.

- Compact and convenient, ideal for paint thickness measurement in confined areas

- Made of anodised aluminium for durability

- Bright LED light source for clear vision

- Range 2 - 2000µm (0.08 - 80mils) Accuracy is dependent on tool cut angle, half a division

- Top Model can hold one cross hatch cutter & three standard cutters which are locked tight, a simple rotation of the cutter holder changes the cutting tool.

Specification

| Tungsten Carbide Cutter No 1 | Angle 45 degree / 20 - 2000 micron (1 - 80mils) |

| Brand | Elcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.) |

| Measuring Range | 2 - 2000 micron (0.08 - 80mils) |

| Dimensions | 110 x 75 x 30 mm (4.3 x 3 x 1.2") |

| Weight | 369g (13oz) |

| Tungsten Carbide Cutter No 6 | Angle 5.7 degree / 2 - 200 micron (0.1 - 8mils) |

| Tungsten Carbide Cutter No 4 | Angle 26.6 degree / 10 - 1000 micron (0.5 - 35mils) |

Precision and Durability

Engineered with anodized aluminum and a stainless steel blade, the Paint Inspection Gauge delivers precise results while maintaining durability in demanding environments. The replaceable tungsten carbide blade ensures a consistent cutting angle and long-lasting efficiency, making it ideal for repeated professional use in the field or laboratory.

User-Friendly Features

Designed for ease of use, this manual device boasts an ergonomic, lightweight form. Its integrated scale in both millimeters and mils allows quick and accurate measurements, while the dial gauge analog display provides instantaneous, clear feedback. The included protective carrying case further enhances portability, making it convenient for on-site inspections.

Compliance and Quality Assurance

The gauge meets internationally recognized standardsISO 2808 and ASTM D4138. This ensures its reliability and acceptance for professional coating evaluations. Users benefit from assured accuracy (0.01 mm) and high resolution, supporting quality control and compliance across various industries.

FAQs of Paint Inspection Gauge:

Q: How is the Paint Inspection Gauge used to measure coating thickness?

A: The Paint Inspection Gauge is manually operated by positioning its blade on the specimen and drawing it across the surface. The integrated scale and dial analog display deliver an instant reading of the coating thickness, ensuring accurate results within a range of 0 to 2 mm.Q: What types of surfaces can be inspected with this gauge?

A: This gauge is suitable for coatings with a thickness up to 2 mm and requires a minimum specimen area of 20 mm wide. It is ideal for evaluating paint on metals, plastics, and other coated surfaces commonly encountered in industrial and quality control settings.Q: When should a blade be replaced in the gauge?

A: The replaceable tungsten carbide blade should be replaced when it shows signs of wear or diminished cutting performance, ensuring continued precision and reliable thickness measurements during multiple inspections.Q: Where can the Paint Inspection Gauge be used?

A: Thanks to its portable, handheld design, the gauge can be used on-site, in laboratories, and across diverse industrial settings. It operates efficiently within temperatures of 5C to 50C and humidity up to 85% RH non-condensing.Q: What is the process for preparing a specimen for measurement?

A: Ensure the specimen area is clean and at least 20 mm wide. Position the gauge according to the manufacturers instructions, then manually operate it to make a single cut for each test to obtain accurate results.Q: What are the main benefits of using this gauge?

A: Key benefits include precise and instant readings, compliance with ISO and ASTM standards, durable construction, portability due to its lightweight form, and a protective carrying case for convenient transport and storage.Q: How accurate are the measurements provided by the gauge?

A: The gauge offers an impressive accuracy of 0.01 mm with a resolution of 0.01 mm, ensuring that each measurement is consistent and reliable for professional quality assurance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Inspection Category

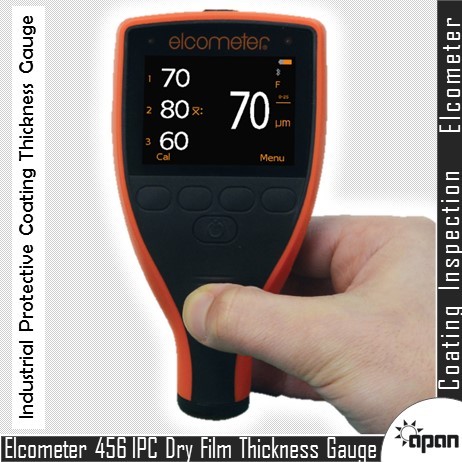

Ferrous Metal Coating Thickness Gauge

Display Type : LCD Digital Display

Machine Weight : 120 g

Accuracy : (2% + 1 m)

Resolution : 1 m

Test Range : 0 to 1250 m

Humidity : 85% RH

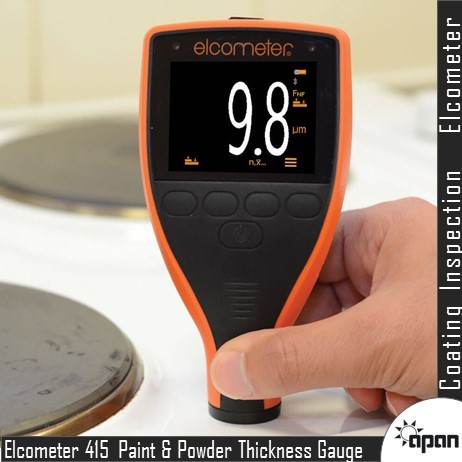

Industrial Paint & Powder Thickness Gauge

Display Type : LCD digital display

Machine Weight : 350 g

Accuracy : (2%+1 m)

Resolution : 0.1 m

Test Range : 01250 m

Humidity : Up to 80% RH

Surface Profile Gauge

Display Type : Analog (dial indicator)

Machine Weight : 350 g

Accuracy : 0.01 mm

Resolution : 0.01 mm

Test Range : 025 mm

Humidity : 2090% RH (operating)

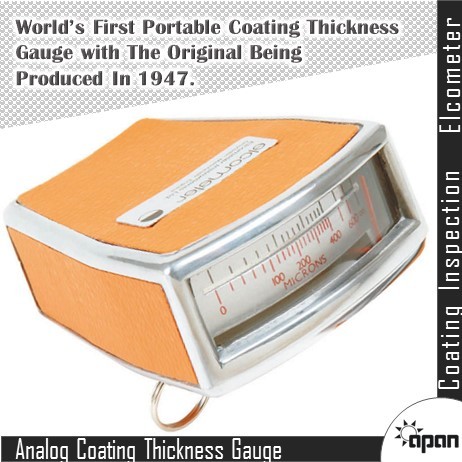

Analog Coating Thickness Meter

Display Type : Analog Dial Gauge

Machine Weight : 1.5 kg

Accuracy : 2% of reading or 2 m (whichever is greater)

Resolution : 1 m

Test Range : 0 1000 m (microns)

Humidity : 85% RH

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry