Shore Durometer Hardness Test Block

Shore Durometer Hardness Test Block Specification

- Accuracy

- 1 Shore unit

- Features

- Colour-coded, labelled for easy identification

- Number of Specimens

- Typically 5 blocks/set

- Mounting Type

- Tabletop/Bench use

- Equipment Type

- Hardness Calibration Test Block

- Humidity

- 85% RH (for testing environment)

- Test Range

- 20 to 90 Shore A/D

- Max Height

- 8 mm (single block)

- Response Time

- Immediate

- Automation Grade

- Manual

- Hardness

- 20/30/40/50/60/70/80/90 Shore A or D

- Power Supply

- Not Required (Passive device)

- Temperature

- 23C 2C (for testing environment)

- Application

- Calibration and verification of Shore Durometers

- Measuring Range

- Varies: Available in different Shore values

- Specimen Size

- 50 mm x 50 mm x 8 mm (typical)

- Resolution

- 1 Shore unit

- Usage

- Reference standard for hardness testers

- Machine Weight

- Approx. 100 g each block

- Test Speed

- Manual

- Test Width

- 50 mm

- Shore Scale Compatibility

- Shore A, Shore D (based on block type)

- Surface Finish

- Smooth, low-variance

- Shelf Life

- Recommended replacement every 12-24 months

- Block Set Contents

- Typically includes a certificate of calibration

- Colour Identification

- Different Shore values in distinct colours

- Material

- Specially formulated rubber or elastomer

- Case

- Supplied with protective storage case

Shore Durometer Hardness Test Block Trade Information

- Main Export Market(s)

- Asia

About Shore Durometer Hardness Test Block

Widely renowned as the leading entity in market, we are offering a high grade Shore Durometer Hardness Test Block to clients. This instrument is extensively used for testing the hardness of elastomers and plastics. Available for clients in a wide range of specifications and models, this Shore Durometer Hardness Test Block is inspected by our expert team based on its durability.

Features:

- Excellent impact strength

- Rugged design

- Durable quality

Reliable Calibration for Shore Durometers

These hardness test blocks are designed for the precise calibration and verification of Shore Durometers (Type A or D), ensuring accurate hardness readings. With clearly labelled, colour-coded blocks and included calibration certification, users can rely on these reference standards for consistent equipment performance in laboratory or industrial environments.

Ease of Use and Durability

Each block in the set is lightweight and sized for convenient manual testing. The blocks require no power, are ready for immediate use, and come with a sturdy protective case for safe storage. Recommended for replacement every 1224 months, they ensure repeatable results while withstanding regular calibration routines.

FAQs of Shore Durometer Hardness Test Block:

Q: How are Shore Durometer Hardness Test Blocks used for calibration?

A: Shore Durometer Hardness Test Blocks serve as reference standards to verify and calibrate Shore Durometers. Operators place the durometer on the colour-coded block with a known hardness value, ensuring the instrument reads within the specified accuracy (1 Shore unit). This process helps maintain the reliability of hardness measurements.Q: What are the key features that differentiate these test blocks?

A: These blocks offer shore scale compatibility (A or D), smooth low-variance surfaces, colour identification for distinct hardness values, and each set is supplied with a certificate of calibration. Their passive design means no power supply is needed, and they are encased in a protective storage case for durability.Q: When should the test blocks be replaced?

A: It is recommended to replace Shore Durometer Hardness Test Blocks every 1224 months to ensure consistent and accurate calibration performance, as the properties of rubber or elastomer materials can change gradually over time.Q: Where are these test blocks most effectively used?

A: These blocks are ideal for use in calibration laboratories, quality control departments, manufacturing facilities, and anywhere Shore Durometers are routinely employed to measure elastomer or rubber hardness. Their environmental tolerance includes 85% relative humidity and 232C testing temperature.Q: What is the benefit of using colour-coded and labelled test blocks?

A: Colour-coded and labelled blocks provide quick and accurate identification of Shore hardness values, reducing the risk of mix-ups during calibration. This enhances workflow efficiency and ensures that the calibration process remains accurate and straightforward.Q: What is the standard process for verifying a durometer using these blocks?

A: To verify a Shore Durometer, select the appropriate block matching the desired Shore value, place it securely on a tabletop or bench, and press the durometer onto the block manually. Compare the reading to the blocks indicated hardness and refer to the calibration certificate for acceptable tolerance (1 Shore unit).Q: What applications do these hardness calibration blocks support?

A: These blocks support the calibration and verification of Shore hardness testers on materials such as rubber and elastomers. They are crucial for distributors, exporters, importers, suppliers, traders, and wholesalers seeking to uphold quality standards within various industrial sectors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Hydraulic Brinell Hardness Tester

Specimen Size : Up to 380 mm height x 230 mm depth

Application : Metallurgical, foundries, forging industry, and quality control labs

Machine Weight : Approx. 100 kg

Control Mode : Manual Hydraulic

Usage : Brinell Hardness Measurement

Test Speed : Adjustable

Portable Hardness Tester ASTM A956

Specimen Size : Minimum weight 0.1 kg (with support ring)

Application : Metallic material hardness measurement

Machine Weight : 0.5 kg

Control Mode : Digital/Manual

Usage : Industrial/Field Hardness Testing

Test Speed : Adjustable, up to 180 tests/hour

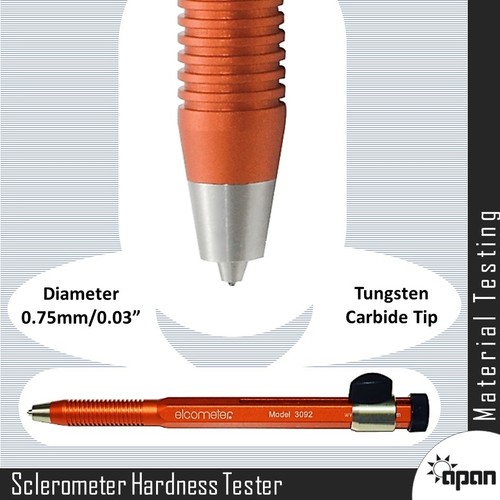

Sclerometer Hardness Tester

Specimen Size : 165 x 24 x 16mm

Application : Hardness Testers

Machine Weight : 370g Gram (g)

Control Mode : Manual

Usage : Surface Hardness Testing

Test Speed : Manual

Ultrasonic Hardness Tester

Specimen Size : Minimum thickness 3mm

Application : Metals Hardness Measurement

Machine Weight : 2 kg

Control Mode : Digital Control

Usage : Nondestructive Testing

Test Speed : Adjustable

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry