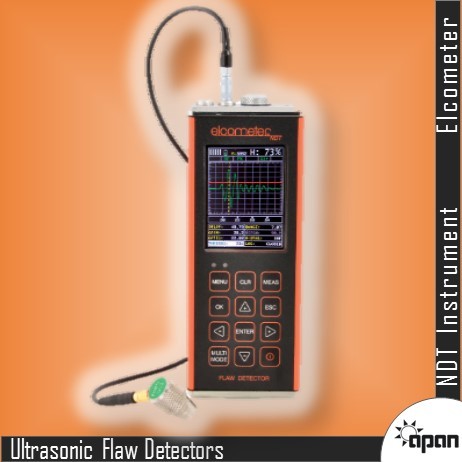

Ultrasonic Flaw Detector

Ultrasonic Flaw Detector Specification

- Specimen Size

- Any size within probe capability

- Power Supply

- DC 7.2V Rechargeable Lithium Battery / AC Adapter

- Interface Type

- USB/BNC

- Equipment Type

- Ultrasonic Flaw Detector

- Mounting Type

- Handheld

- Measuring Range

- 0.5 mm - 9999 mm (in steel)

- Display Type

- 5.7 inch TFT color LCD

- Frequency

- 0.5 MHz - 20 MHz (probe dependent)

- Accuracy

- 0.1 mm

- Port Size

- BNC connector

- Response Time

- Instantaneous digital display

- Test Range

- 0-9999 mm (steel)

- Application

- Detection of flaws in metal, welds, castings, and other solid materials

- Temperature

- -10C to +50C

- Humidity

- 20-90% RH (non-condensing)

- Features

- Lightweight, portable, easy operation, high contrast display

- Automation Grade

- Semi-Automatic

- Number of Specimens

- Single/Batch Mode

- Resolution

- 0.01 mm

- Operating Voltage

- 7.2V DC (Battery)

- Usage

- Industrial Non-Destructive Testing

- Capacity

- Internal data storage for up to 1000 A-scans

- Machine Weight

- 1.2 kg (approx.)

- Test Speed

- Real-time digital processing

- Test Width

- Variable depending on probe

- Control Mode

- Manual/Automatic

- Battery Backup Time

- Up to 8 hours of continuous use

- Dimensions

- Approx. 263 x 170 x 61 mm

- Calibration

- Automatic and manual calibration modes

- Pulse Repetition Frequency

- 10 Hz to 1000 Hz adjustable

- Alarm System

- Audible/Visual flaw alarm

- Vertical Linearity Error

- 3%

- Language Support

- Multilingual interface

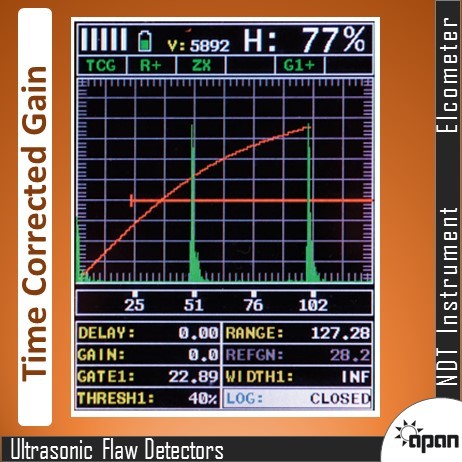

- Gain Adjustment

- 0-110dB digital adjustable

- Probe Type

- Single/Double (standard and angle beam compatible)

- Horizontal Linearity Error

- 0.1%

- Software Update

- USB upgradable

- PC Connectivity

- USB cable and optional Bluetooth module

- Enclosure Protection

- IP54

- A-Scan Storage

- Supports 1000 data sets

Ultrasonic Flaw Detector Trade Information

- Main Export Market(s)

- Asia

About Ultrasonic Flaw Detector

As an Authorized dealer we are engaged in providing the broad assortment of "NDT Instrument" for various applications.

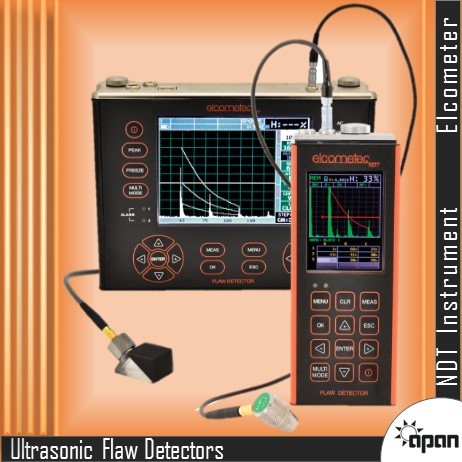

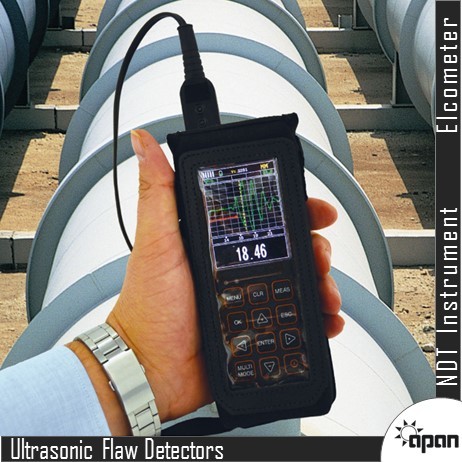

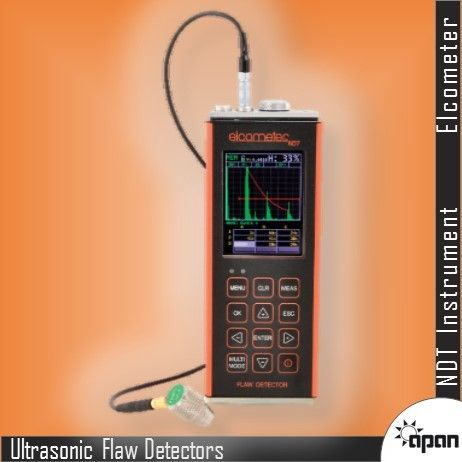

These powerful bench top & hand-held mini flaw detectors combine state of-the-art flaw detection with advanced ultrasonic material thickness capabilities.

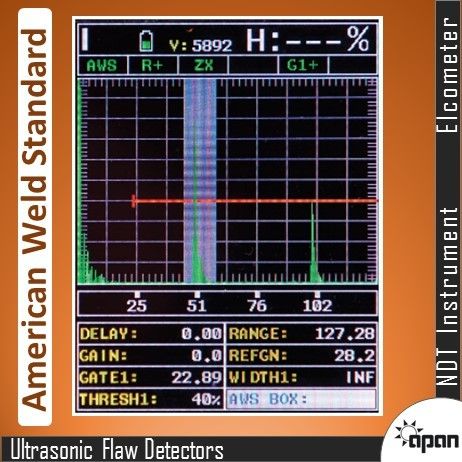

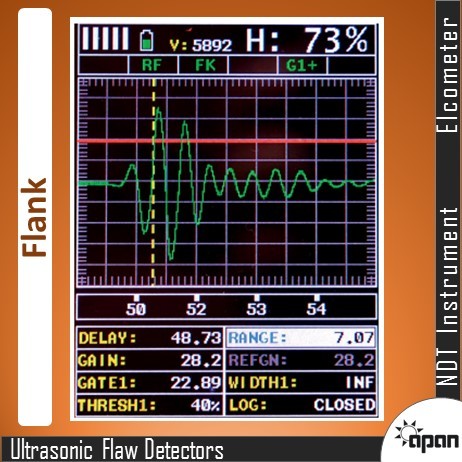

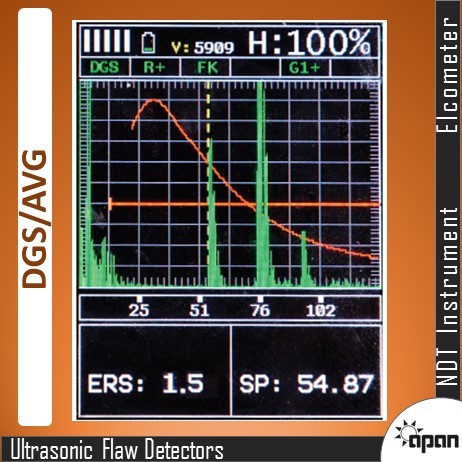

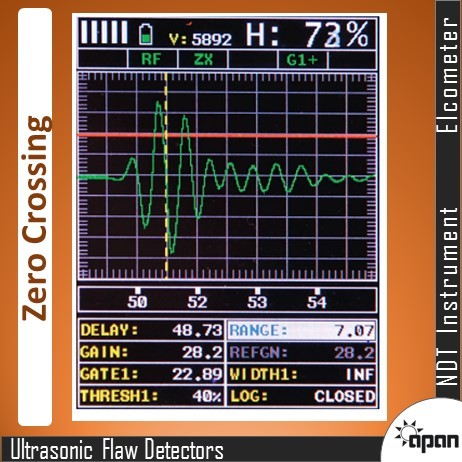

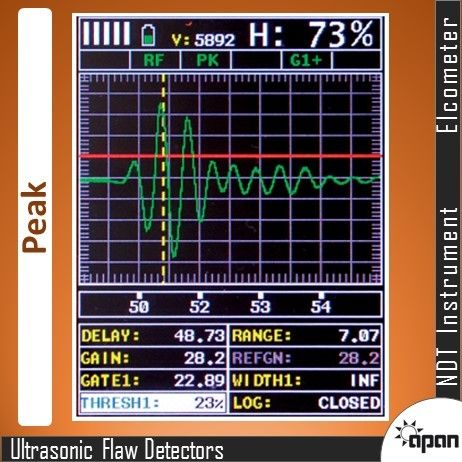

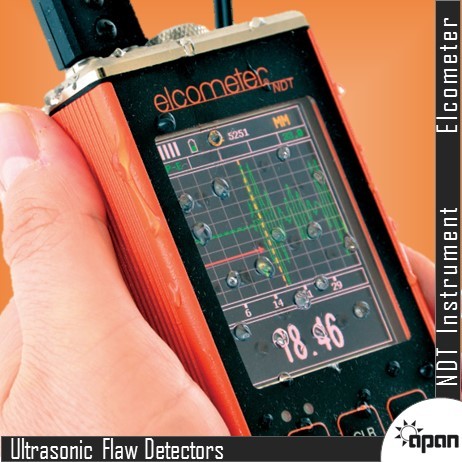

The Elcometer FD700 and FD800 range, when in flaw detection mode, offers a variety of tool kits which enable fast and accurate flaw detection, ideal for weld inspection, forgings or composite material testing.

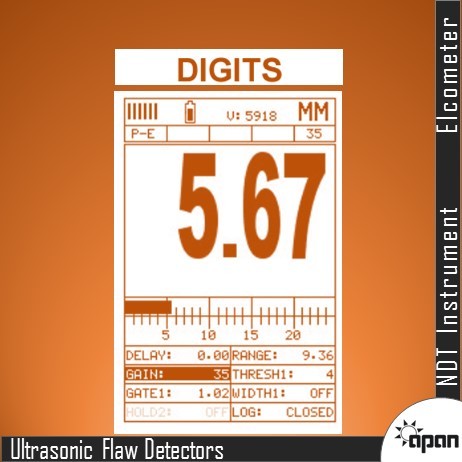

The FD700 series are a combined corrosion gauge and flaw detector that measures with extreme versatility.

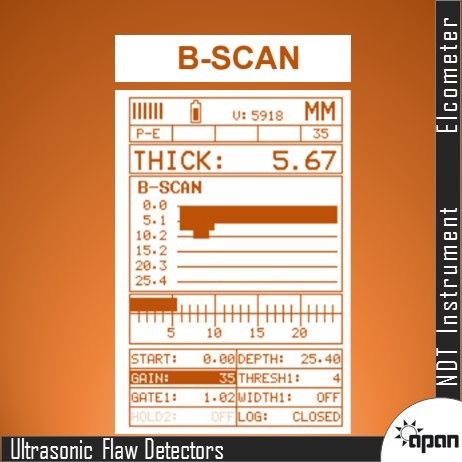

When the GAUGE function is set to THICKNESS GAUGE, the FD700 series becomes a Corrosion Gauge which has the ability to measure coatings and material thickness simultaneously while maintaining the ability to locate pits, flaws and defects in the material. Based on the same operating principles as SONAR, the FD700 series are capable of measuring the thickness of various materials with accuracy as high as +/- 1% or +/- 0.1 millimetres (+/- 0.005 inches) whichever is the greater.

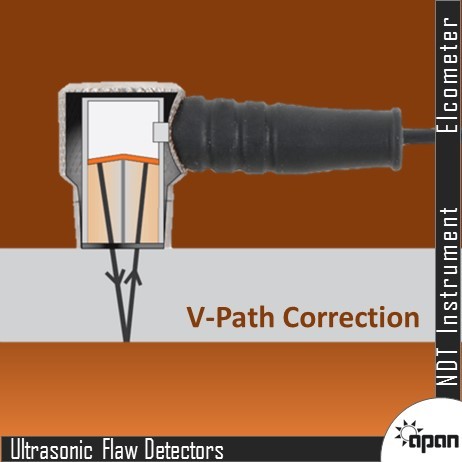

When the GAUGE function is set to FLAW DETECTOR, the gauges become a Flaw Detector which have the ability to detect the size and position of flaws and to differentiate between flaw types in various materials and welded joints.

FEATURES :

- Two gauges in one: Corrosion (thickness) gauge and Flaw Detector

- Wide range of thickness measurement modes: Pulse-Echo, Echo-Echo, Echo-Echo Verify, Coating Only, Pulse-Echo with Temperature Compensation, and Pulse-Echo with Coating

- Automatic: probe zero, probe recognition, and temperature compensation.

- Adjustable gain settings.

- Stores up to 64 custom setups for specific applications.

- High speed scan mode of up to 50 readings per second.

- Audible/visual alarm with high and low limit settings.

- Differential mode for QC inspections.

- Colour display.

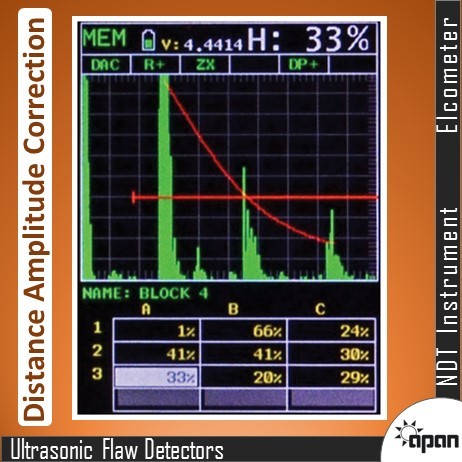

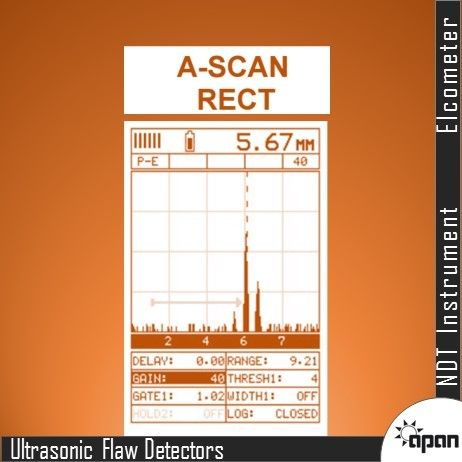

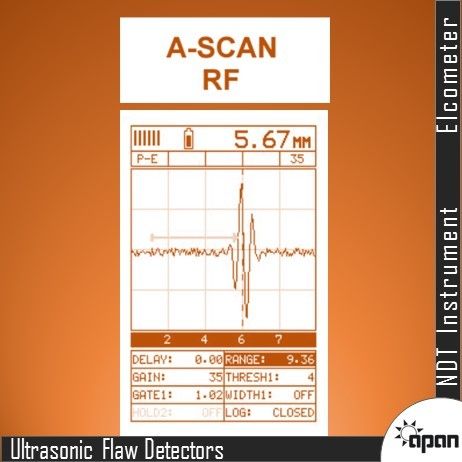

- Radio frequency RF and RECT A-Scan displays.

- Time based B-Scan display for cross section material scans (thickness gauge).

- Measurement data storage formats: Alpha numeric grid and sequential with auto identifier.

- Data can be downloaded to a computer for analysis and storage.

The principal advantage of ultrasonic thickness measurement over traditional methods is that ultrasonic measurements can be performed with access to only one side of the material being measured. The gauges include a data-logging (memory) facility which allows readings and waveforms to be stored in batches before being downloaded to a computer.

Precision Flaw Detection for Industry

This Ultrasonic Flaw Detector combines high accuracy with rugged portability. Suited for weld, metal, and casting inspections, its instantaneous digital processing enables real-time flaw detection and evaluation across a broad measurement range. Lightweight and easy to operate, its designed for frequent use in demanding industrial environments.

User-Friendly Design with Advanced Features

Operators benefit from intuitive menus, automatic and manual calibration modes, and comprehensive gain adjustment from 0110 dB. The clear 5.7-inch TFT LCD, multilingual interface, audible/visual alarms, and compatibility with standard and angle beam probes make this unit versatile and adaptable to various non-destructive testing needs.

FAQs of Ultrasonic Flaw Detector:

Q: How does the Ultrasonic Flaw Detector identify defects in materials?

A: This device sends ultrasonic pulses into a specimen; reflected signals from flaws or material boundaries are analyzed in real-time using digital processing. Results are displayed instantly, aiding in the detection of cracks, voids, or inclusions in metals, welds, and castings.Q: What types of probes can be used with this flaw detector?

A: The instrument supports both single and double crystal probes, compatible with standard and angle beam configurations. This flexibility allows effective evaluation of various geometries and materials, depending on inspection requirements.Q: Where can the detector be employed for testing?

A: This portable device is suitable for use in industrial workshops, construction sites, maintenance facilities, and quality control labs. Its IP54 rating ensures protection against dust and splashes, making it ideal for harsh and diverse environments.Q: When should I perform calibration on the detector?

A: Calibration should be performed before each testing session to ensure measurement accuracy. The device provides both automatic and manual calibration modes for user convenience and precise results.Q: What is the process for storing and retrieving inspection data?

A: The detector can store up to 1,000 A-scan datasets internally. Data can be retrieved later for review, reporting, or transfer to a PC using USB or an optional Bluetooth module, enhancing traceability and documentation.Q: How long can the device operate continuously on battery power?

A: With its rechargeable lithium battery, the Ultrasonic Flaw Detector delivers up to 8 hours of continuous usesuitable for long inspection shifts without frequent recharging.Q: What are the main benefits of using this flaw detector for industrial testing?

A: Key advantages include precise flaw detection, rapid response time, robust construction, easy operation, and comprehensive data management. It significantly enhances safety and quality control for distributors, exporters, suppliers, and industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NDT Equipment Category

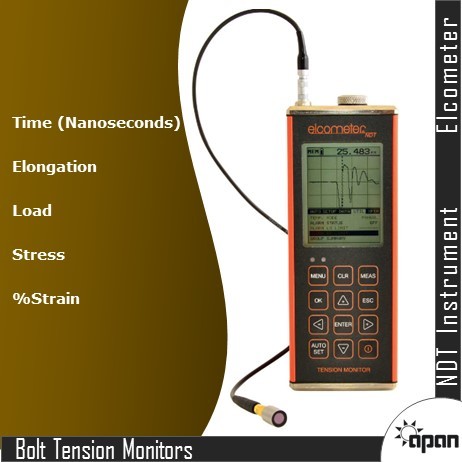

Bolt Tension Monitors

Machine Weight : 4.2 kg

Operating Voltage : 220 V AC

Humidity : 2085% RH

Features : Portable, High Accuracy, Data Logging

Control Mode : Digital

Automation Grade : Automatic

Flaw Detector Transducers

Machine Weight : 1.5 kg

Operating Voltage : Receives from flaw detector unit

Humidity : 85% RH

Features : Durable housing, high accuracy, quick response

Control Mode : Manual/Automatic

Automation Grade : Semiautomatic

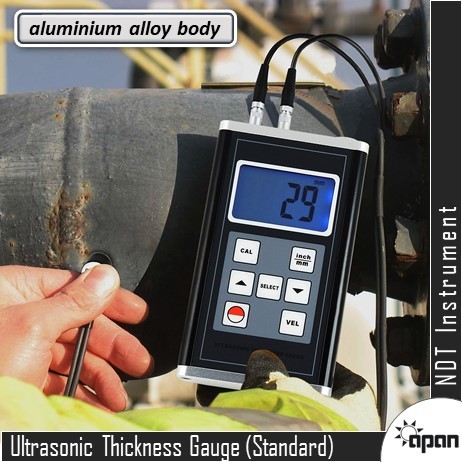

Ultrasonic Thickness Gauge (Standard)

Machine Weight : 200 g (approx)

Operating Voltage : 3V DC (2xAA)

Humidity : 85% RH

Features : Backlight display, Auto shutdown, Low battery indicator

Control Mode : Manual

Automation Grade : Manual

Ultrasonic Thickness Gauge

Machine Weight : 180 g (including batteries)

Operating Voltage : 3V DC

Humidity : <85% RH

Features : Auto shutdown, Low battery indication, Lightweight & portable, Data hold

Control Mode : Manual

Automation Grade : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry