Bolt Tension Monitors

Bolt Tension Monitors Specification

- Equipment Type

- Bolt Tension Monitor

- Port Size

- M12

- Measuring Range

- 0-100 kN

- Application

- Measuring bolt tension during tightening

- Temperature

- 0C to 50C

- Mounting Type

- Handheld

- Humidity

- 20-85% RH

- Resolution

- 0.01 kN

- Frequency

- 50 Hz

- Specimen Size

- M12 to M36 bolts

- Accuracy

- 1% F.S.

- Features

- Portable, High Accuracy, Data Logging

- Response Time

- <2 seconds

- Test Range

- 0-100 kN

- Number of Specimens

- 1

- Max Height

- 150 mm

- Automation Grade

- Automatic

- Interface Type

- RS232/USB

- Power Supply

- 220 V AC, 50 Hz

- Gas Pressure

- 0.5-0.8 MPa

- Operating Voltage

- 220 V AC

- Display Type

- Digital LCD Display

- Usage

- Bolt tension measurement

- Capacity

- 100 kN

- Machine Weight

- 4.2 kg

- Test Speed

- 0.3-5 mm/min

- Test Width

- Up to 30 mm

- Test Stroke

- 10 mm

- Control Mode

- Digital

- Data Output

- CSV/Excel Format Export

- Memory

- Stores up to 1000 Test Results

- Power Backup

- Built-in Rechargeable Battery

- Protection Class

- IP54

- Calibration

- Factory Calibrated with Calibration Certificate

- Material

- Stainless Steel Body

- Alarm Function

- Audio/Visual Alerts for Overload

- Transducer Type

- Strain Gauge

About Bolt Tension Monitors

As a Authorized dealer we are engaged in providing the broad assortment of "NDT Instrument" for various applications.

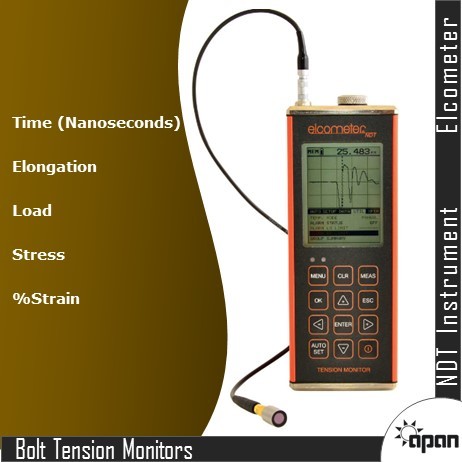

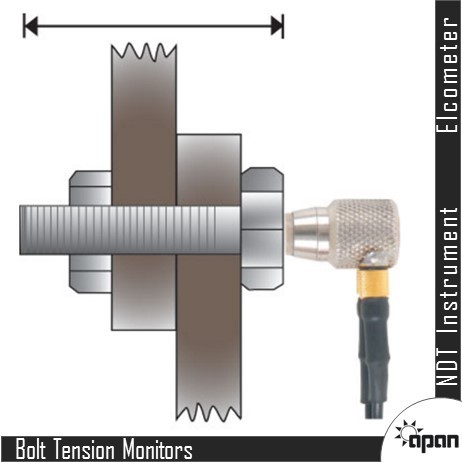

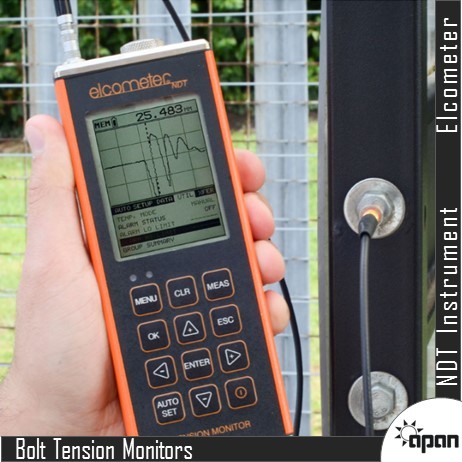

The Models BG80TD & BG80TDL are tension monitors that measure the change in length of a fastener when a load is put to the fastener. Within the elastic limit of the fastener, the change of length is proportional to the load given, and therefore by measuring the change of length and knowing the physical properties of the fastener, the load on the fastener can be calculated. Based on the same operating principles as SONAR, the Models BG80TD & BG80TDL are capable of measuring the length of fasteners of various materials with accuracy as high as 0.0001 millimetres (0.00001 inches). Your gauge can measure time, elongation, load, stress or %strain in fasteners of virtually any material from 25.4 mm to 1220mm in length. By storing the reference waveform and displaying it for comparison while the elongation is being measured, the gauge minimises operator training. The Models BG80TD & BG80TDL include a data-logging (memory) facility which allows readings to be stored in groups before being downloaded to a computer.

Your gauge can be used in accordance with the following Standards and test methods; ASTM E 797, EN 14127 and EN 15317.

FEATURES :

- Measurement quantities: Time (nanoseconds), Elongation, Load, Stress, and % Strain.

- Display Options: RF, RECTified, Large DIGITS with Limits Bar.

- Display Resolution 1/8 VGA 240 x 160 pixels.

- Stores 8000 readings and waveforms in multiple groups.

- Built-in Linear regression or vector for optimising load measurements.

- Auto Set function which automatically optimises detection and adjusts display.

- Hi/Lo alarm tolerance limits work in conjunction with the data port and external pump shut-off device.

- Alpha numeric measurement data storage. Data can be downloaded to a computer for analysis and storage.

How does it work ?

- As a fastener is tightened it stretches (elongates) in length.

- Manual torque wrenches measure the force given when tightening a fastener, the accuracy can be affected by temperature, friction and resistance.

- As BG80 & BG80TDL ultrasonically measures the change in length accurately determining the given load of a fastener as it is tightened, they are not affected by these factors.

Specification

Model & Part Number | BG80DL & BG80TDL |

Material thickness digits display | YES |

Measurement Mode1 | PE & PE with Gate |

Measurement Rate: | |

Measuring Range2 | 25.4 2440mm (1 96 inches) |

Measurement Accuracy2 | 1% or 0.1mm whichever is the greater |

Measurement Resolution | 0.0001mm (0.00001 inch) |

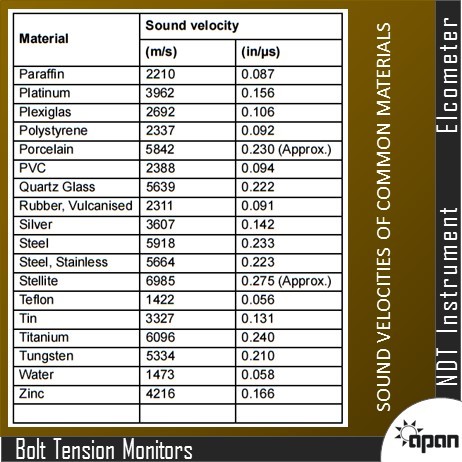

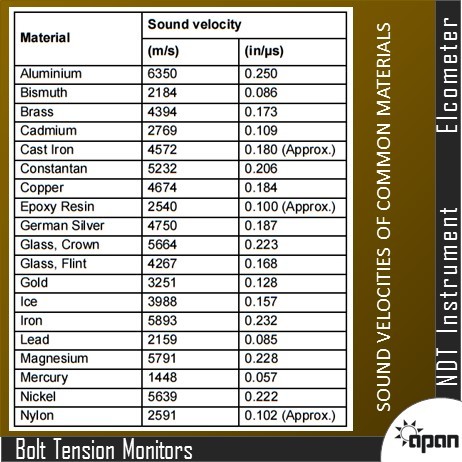

Velocity Calibration Range | 1250 - 10,000m/s |

| Additional Features: |

|

| Limit alarm mode | |

| Data logging | 8,000 readings |

| Calibration Options | fixed, single & 2 point |

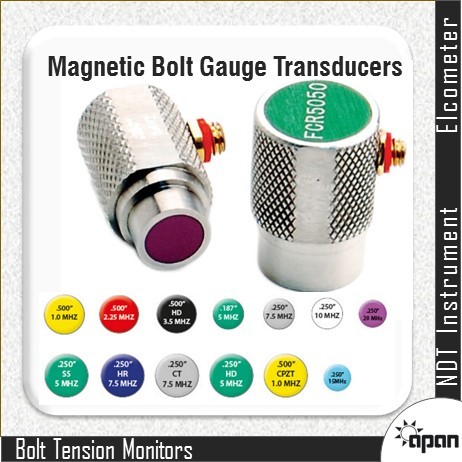

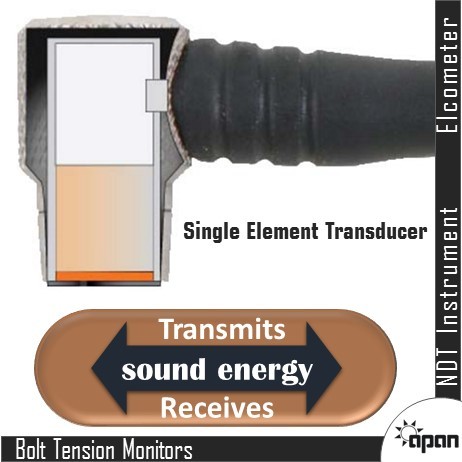

| Transducer Probe Type | single element |

| Transducer Frequency Range | 1 - 10MHz |

| Display | 1/8 VGA |

| Units (selectable) | mm or inches |

| LED Backlight | on / off / auto |

| Repeatability / Stability Indicator | yes |

| Battery Type | 3 x AA alkaline |

| Battery Life (approximate) | 150 hours |

| Low Battery Indicator | YES |

| Battery Save Mode | auto |

| Operating Temperature | -10 to 60(14 to 140F) |

| Size (w x h x d) | 63.5 x 165 x 31.5mm 2.5 x 6.5 x 1.24 inches |

| Weight (including batteries) | 383g (13.5oz) |

High-Precision Bolt Tension Measurement

This device ensures highly accurate measurement of bolt tension, essential for safety and reliability in various engineering and assembly applications. The strain gauge transducer and digital control system guarantee swift and consistent results, suitable for both field and laboratory use.

Comprehensive Data Storage and Export

Easily track and manage testing results thanks to integrated memory, which stores up to 1000 test results. You can conveniently export your data in universally compatible CSV and Excel formats using RS232 or USB interfaces, streamlining reporting and analysis.

Robust Design with User-Friendly Features

The stainless steel body and IP54 protection make the Bolt Tension Monitor durable in challenging environments. Its audio/visual alarms, automatic operation, and handheld mounting type enhance usability, while rechargeable power backup ensures uninterrupted testing.

FAQs of Bolt Tension Monitors:

Q: How does the Bolt Tension Monitor accurately measure bolt tension?

A: The monitor uses a strain gauge transducer to precisely assess tension forces in bolts during tightening. Digital control, factory calibration, and high-resolution output (0.01 kN) contribute to reliable and consistent results.Q: What is the benefit of the devices built-in data storage and export capability?

A: It can store up to 1000 test results, ensuring easy record-keeping. The CSV/Excel export feature allows for seamless integration with quality control systems and aids in detailed analysis and reporting.Q: When should I use the audio/visual alarm function provided by this monitor?

A: The alarm function is triggered during overload situations, notifying users instantly through audio and visual signals to prevent excessive force and ensure safe tightening.Q: Where can the Bolt Tension Monitor be utilized?

A: This monitor is suitable for use in industrial assembly lines, maintenance workshops, site inspections, and laboratories across various sectors including construction, manufacturing, and automotive.Q: What is the process for calibrating the monitor?

A: Each unit is factory calibrated and accompanied by a calibration certificate. Routine recalibration isnt required immediately, but periodic checkups can be arranged at authorized service centers for optimal performance.Q: How does the device support users during power outages?

A: The built-in rechargeable battery provides reliable power backup, enabling uninterrupted operation even during electricity disruptions.Q: What makes this device advantageous for bolt tension measurement?

A: Its portable, handheld design, automatic operation, high accuracy, robust construction, and comprehensive data management make it a preferred solution for efficient bolt tension monitoring.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NDT Equipment Category

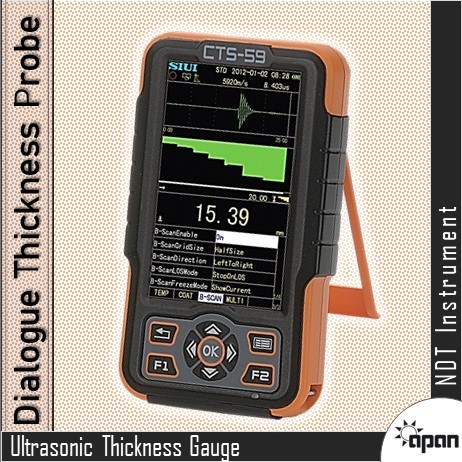

Smart Ultrasonic Thickness Gauge

Control Mode : Manual

Humidity : 85% RH

Mounting Type : Handheld

Temperature : 0 ~ 40C

Resolution : 0.1 mm

Frequency : 5 MHz

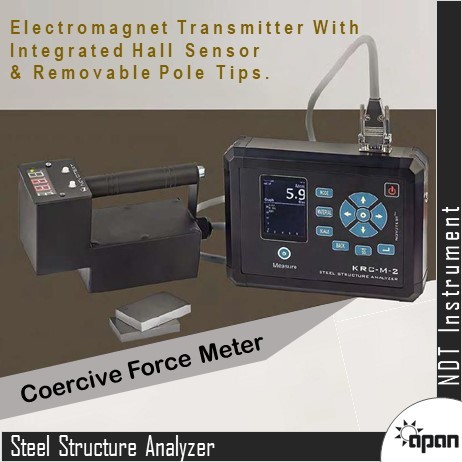

Steel Structure Analyzer

Control Mode : Automatic / Manual

Humidity : 10% 85% RH

Mounting Type : Benchtop

Temperature : 5C to 40C

Resolution : 0.1 unit

Frequency : 50 Hz

Flaw Detector Transducers

Control Mode : Manual/Automatic

Humidity : 85% RH

Mounting Type : Handheld, clamp optional

Temperature : 0C to 50C

Resolution : 0.01 mm

Frequency : 2.5 MHz, 5 MHz, 10 MHz (options)

Precision Ultrasonic Thickness Gage

Control Mode : Manual

Humidity : 85% RH

Mounting Type : Handheld

Temperature : 10C to 60C

Resolution : 0.1 mm / 0.01 mm selectable

Frequency : 5 MHz (standard).

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry