Conical Mandrel Bend Tester

Conical Mandrel Bend Tester Specification

- Power Supply

- No electricity required

- Mounting Type

- Bench-top

- Display Type

- None; visual inspection

- Number of Specimens

- 1 at a time

- Resolution

- N/A (manual analog)

- Frequency

- N/A; operated on demand

- Specimen Size

- Width up to 75 mm, Length 150 mm

- Measuring Range

- 3 mm to 38 mm conical mandrel

- Features

- Detachable handle, adjustable clamping bar, easy-clean baseplate

- Interface Type

- Manual/mechanical

- Equipment Type

- Conical Mandrel Bend Tester

- Response Time

- Immediate, manual

- Accuracy

- Dimensional tolerance 0.1 mm

- Hardness

- Mandrel: Steel, hardened

- Test Range

- Diameter: Large end 38 mm, Small end 3 mm

- Automation Grade

- Manual

- Max Height

- Approx. 120 mm

- Application

- Evaluating resistance of coatings to cracking or detachment from metal substrates during bending

- Temperature

- 10C to 40C (operating)

- Humidity

- Standard lab environment

- Usage

- Paint, varnish, and coating inspection

- Capacity

- Single specimen

- Machine Weight

- Approx. 7.5 kg

- Test Speed

- Manual operation

- Test Width

- Approximately 75 mm

- Test Stroke

- Full length of conical mandrel

- Control Mode

- Manual

About Conical Mandrel Bend Tester

As a Authorized dealer we are engaged in providing the broad assortment of "Elasticity and Deformation Tester" including

Mandrel Bend Tester, Impact Tester, Cupping Tester.

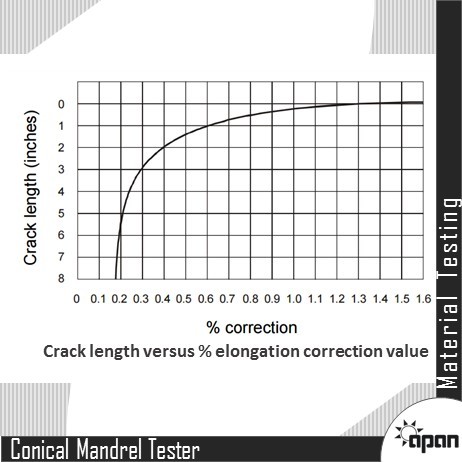

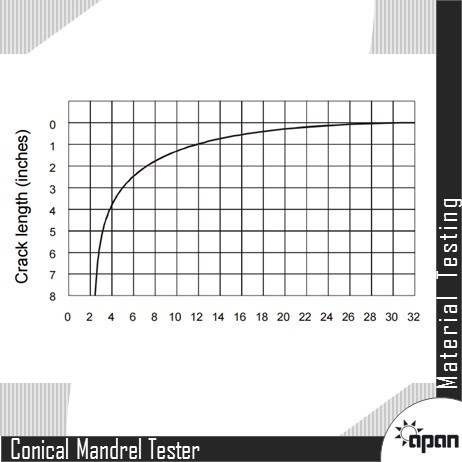

The Elcometer 1510 Conical Mandrel Bend Tester is used to determine the effects of bending on the elasticity, adhesion and elongation properties of cured coatings on sheet metal.

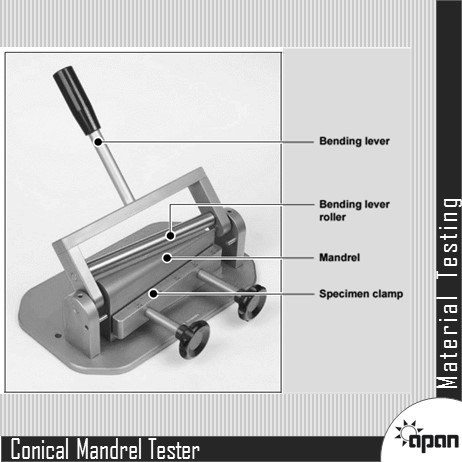

The frame has a bending lever with a roller which pivots on a steel conical mandrel with a diameter from 3.2 - 38.1mm (0.12 - 1.5 ). A graduation indicates the mandrel diameter in both mm and inches.

Specimens should be prepared according to the requirements of the test standard. Specimens should be flat, free from distortion and the coated surface should not contain any visible cracks.

The specimen can be bent on part of, or along, the entire length of the mandrel, and the results (cracks) corresponding to different test diameters can be observed in a single operation. This is ideal for use in conjunction with the cylindrical mandrel, as it identifies the stop point for more focused testing.

As the instrument is machined out of a solid block of steel, the particularly robust and rigid construction provides excellent resistance to wear and provides long service life. A large, sturdy anodised base, which can be permanently fixed to a workstation, ensures stability during testing.

Specification

- 3.2 - 38.1mm

- 3.2 - 38.1mm

- Sample Size : 180 x 100 x 0.8mm

- Dimensions :325 x 350 x100mm

- Weight : 9kg (20lb)

Users of the Conical Mandrel Bend Tester may also benefit from the following products:

- Elcometer 1506 Cylindrical Mandrel Bend Tester

- Elcometer 1615 Variable Impact Tester

- Elcometer 1620 Cupping Tester

- Elcometer 1542 Cross Cut Adhesion Tester

Superior Construction for Longevity

Crafted with a high-grade steel body and reinforced with a corrosion-resistant powder-coated finish, this tester ensures durability against wear and laboratory conditions. Its hardened mandrel and easy-clean baseplate cater to frequent inspection demands, providing sustained performance over years of rigorous use.

Manual Precision and User-Friendly Operation

Designed for simple manual operation, the conical mandrel bend tester features a quick-action clamp and ergonomic detachable handle. These elements make specimen mounting and testing straightforward, fostering effective inspection workflows. With no requirement for electricity, it seamlessly integrates into standard bench-top setups.

Versatile Application for Accurate Coating Assessment

Engineered to evaluate the resistance of coatings to cracking or detachment, this tester handles a wide range of specimen sizes and coatings. Typical applications include inspection of paints and varnishes in industrial and research settings, supporting quality assurance and product development efforts.

FAQs of Conical Mandrel Bend Tester:

Q: How does the Conical Mandrel Bend Tester operate for coating assessments?

A: The tester works through manual operation by clamping the specimen onto the mandrel and bending it along its full conical length. Observers then visually inspect the sample to determine if cracks or detachment have occurred, providing immediate feedback on the coatings flexibility and adhesion.Q: What is the process for preparing and testing specimens?

A: To test a specimen, first clamp a coated metal strip (up to 75 mm wide, 1 mm thick, and 150 mm long) using the quick-action mechanical clamp. Engage the detachable handle to bend the specimen along the mandrels full length, covering diameters from 3 mm to 38 mm, then visually inspect the results.Q: When should this tester be used in industrial or laboratory settings?

A: Use the conical mandrel bend tester during quality inspections, product development, or whenever evaluating the resistance of coatings to bending stress. It is particularly beneficial for routine testing as part of manufacturing or research protocols in paint, coating, or varnish production.Q: Where is the optimal environment for operating the tester?

A: Operate the tester in a standard laboratory with ambient temperatures between 10C and 40C and normal humidity levels. Ensure it is securely placed on a bench-top for safe and stable manual operation.Q: What benefits does this equipment offer for paint or coating inspection?

A: This tester provides accurate, immediate visual assessment of flexible coating performance, helping manufacturers ensure coatings adhere well and resist cracking. Its manual design allows for quick, electricity-free evaluations, essential for fast-paced labs or field use.Q: How is calibration maintained and verified for this instrument?

A: Each unit comes with a calibration certificate, confirming dimensional tolerance to 0.1 mm. Regular checks using reference specimens and adherence to the included user manual ensure ongoing accuracy and reliable test results.Q: What is included in the package when purchasing the tester?

A: The package contains the main conical mandrel bend tester instrument, a comprehensive user manual for operation and maintenance reference, and a calibration certificate that verifies the instruments accuracy and suitability for industrial standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Digital VickersHardness Tester

Application : Hardness testing for metals, alloys, and other materials

Hardness : Vickers (HV)

Accuracy : 1%

Automation Grade : SemiAutomatic

Number of Specimens : Single Specimen

Resolution : 0.1 HV

Tablet Hardness Tester

Application : Measuring tablet crushing strength

Hardness : 240 kg

Accuracy : 0.5 kg

Automation Grade : Manual

Number of Specimens : 1 tablet at a time

Resolution : 0.1 kg

Leeb Hardness Tester

Application : Testing the hardness of steel, cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminium, brass, bronze, copper, and other materials

Hardness : Leeb hardness (HL), can convert to HRC, HB, HV, HS, etc.

Accuracy : 6 HL (0.5% at 800 HL)

Automation Grade : Manual

Number of Specimens : Single or multiple, depending on application

Resolution : 1 HL

Webster Hardness Tester

Application : Onsite rapid hardness testing of aluminum alloys, copper, brass etc.

Hardness : Webster Scale (HRE)

Accuracy : 1 HRE

Automation Grade : Manual

Number of Specimens : Single point measurement

Resolution : 1 HRE

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry