Flaw Detector Transducers

Flaw Detector Transducers Specification

- Mounting Type

- Handheld, clamp optional

- Specimen Size

- Normal/Custom transducer head sizes (contact area 2-20 mm)

- Accuracy

- 1% of reading

- Number of Specimens

- 1 at a time (single-point)

- Measuring Range

- 0.5 mm 500 mm (material dependent)

- Temperature

- 0C to 50C

- Application

- Industrial ultrasonic flaw detection

- Interface Type

- BNC/Q9 connector

- Display Type

- Digital (with main device)

- Port Size

- Standard probe connector

- Test Range

- 0-5000 mm (steel equivalent)

- Resolution

- 0.01 mm

- Frequency

- 2.5 MHz, 5 MHz, 10 MHz (options)

- Response Time

- < 10 ms

- Automation Grade

- Semi-automatic

- Equipment Type

- Flaw Detector Transducer

- Power Supply

- AC 220V/50Hz

- Operating Voltage

- Receives from flaw detector unit

- Features

- Durable housing, high accuracy, quick response

- Humidity

- 85% RH

- Usage

- Non-destructive testing (NDT)

- Capacity

- High sensitivity flaw detection

- Machine Weight

- 1.5 kg

- Test Speed

- Variable, up to 1500 mm/s

- Test Width

- Up to 80 mm

- Test Stroke

- Adjustable, 0-100 mm

- Control Mode

- Manual/Automatic

- Cable Type

- Shielded coaxial

- Transducer Type

- Contact, normal and angle beam

- Cable Length

- 1.5 m standard (custom available)

- Protection Class

- IP65 (splash/water resistant)

- Connector Type

- BNC plug standard

- Material Compatibility

- Steel, aluminum, alloys, plastics

- Probe Diameter

- 8 mm, 10 mm, 20 mm (as per design)

- Element Material

- Piezoelectric ceramic

- Storage Temperature

- -20C to 70C

About Flaw Detector Transducers

As an Authorized dealer we are engaged in providing the broad assortment of "NDT Instrument" for various applications.

Flaw Detector Transducers

Elcometer NDT offer a state-of-the-art range of ultrasonic flaw detection transducers. Selecting the right ultrasonic transducer for your application is essential to maximise performance.

Frequency :

- Transducers are selected by the frequency and size of the crystal. Frequency of the appropriate transducer is determined by the type of material and expected thickness range. The choice of the crystal size and the angle of the wedge are determined by the access, shape and surface finish of the object to be measured.

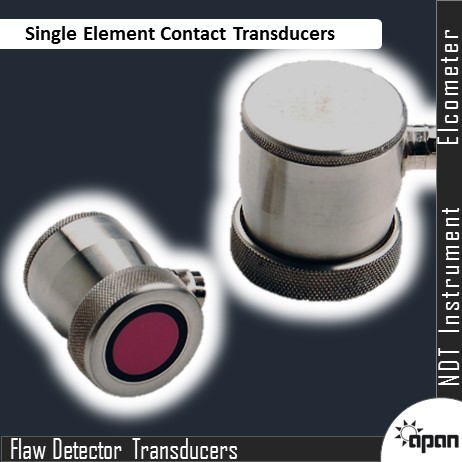

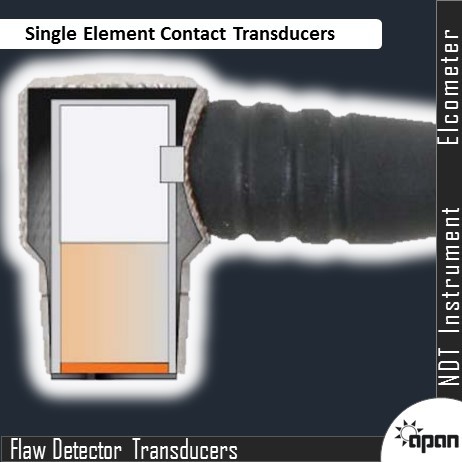

Single Element Contact Transducers

- The contact transducer is placed vertically onto the surface to detect any flaws in the material under inspection. A single element transducer consists of a single crystal element housed in casing. The single crystal both transmits and receives the sound energy.

Shear Wave Standard Transducers

- Shear Wave Standard Transducers can be fixed to wedges of different angles to produce shear wave velocity measurements.

- When used in conjunction with the Trigonometry feature of the gauge, the transducer will produce instrumental flaw detection sound shear waves.

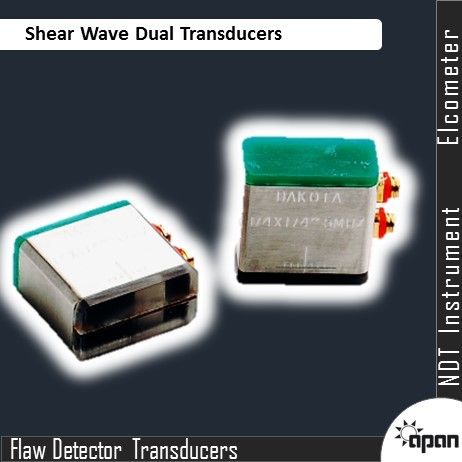

Shear Wave Dual Transducers

- Potted in durable cast housing, the transducers are available in a variety of angles, including 45, 60 or 70, for producing the required shear waves.

- The Shear Wave Dual Transducers are used in conjunction with the Trigonometry function of the gauge.

Shear Wave Quick Change Transducers

- Shear Wave Quick Change Transducers can be used when different frequencies are required using the same wedge, or where different angles are required using the same frequency transducer.

- These transducers are ideal for inspecting curved surfaces and hard to reach areas.

- Shear Wave Quick Change Transducers can be fixed to wedges of different angles to produce shear wave measurements.

- When used in conjunction with the Trigonometry feature of the gauge, the transducer will produce instrumental flaw detection sound shear waves.

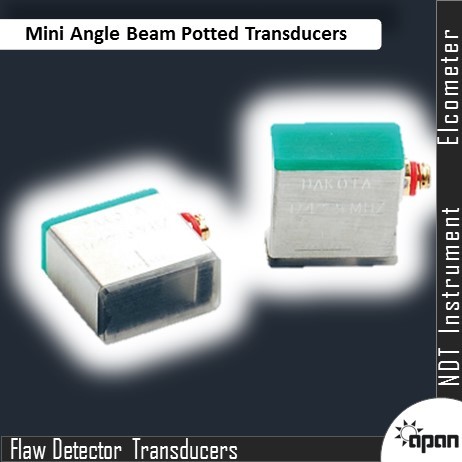

Mini Angle Beam Potted Transducers

- Mini Angle Beam Potted Transducers are single element and are available in a variety of fixed angles, including 45, 60 or 70, for producing the required shear wave measurements.

- The Mini Angle Beam Potted Transducers are used in conjunction with the Trigonometry function of the gauge.

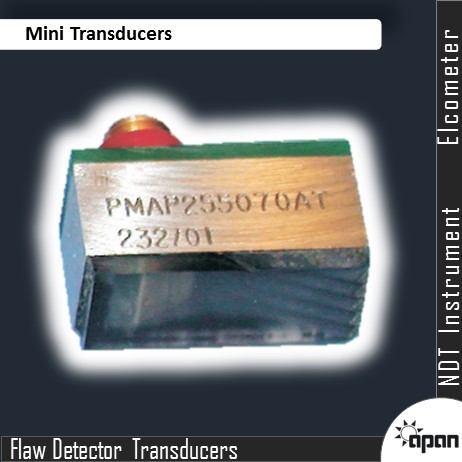

Mini Angle Beam Potted - Mini Transducers

- Available in a variety of fixed angles, including 45, 60 or 70, to produce the required shear waves. These transducers are used in conjunction with the Trigonometry function of the gauge.

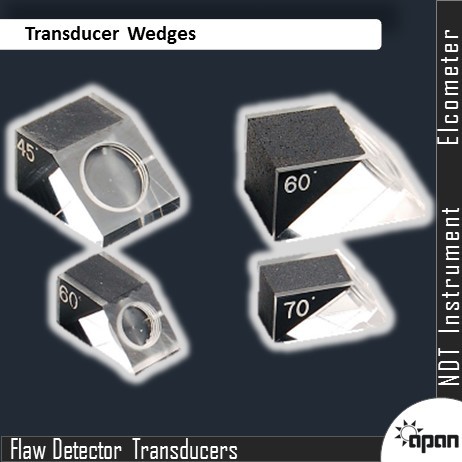

Transducer Wedges

- The transducer wedges for the Shear Wave Standard Transducers are fixed to the transducer with two screws, whilst the quick change wedges for the Shear Wave Quick Change Transducers are threaded.

- The transducer wedges increase the versatility of the transducer enabling it to become an angle transducer of 45, 60 or 70. This allows the transducer to produce shear waves and can be used with the 'Trigonometry' function of the gauge.

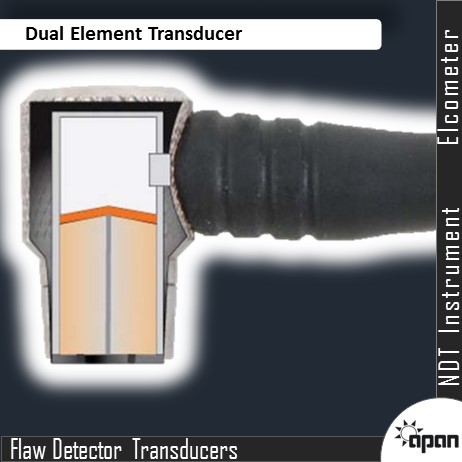

Material Thickness Transducers

- Dual element material thickness transducers are ideal for inspecting metal substrates but can also measure thicknesses of other materials, such as plastic, composites or fibreglass.

Reliable Detection Across Diverse Materials

Engineered for steel, aluminum, alloys, and plastics, these transducers provide exceptional flaw detection capability. The piezoelectric ceramic sensing element enhances accuracy and responsiveness, making them valuable tools for industrial quality assurance. Suitable for both contact and angle beam testing, the probes adapt efficiently to different material types and inspection needs.

Versatile Probe Options and Operation Modes

Choose from probe diameters of 8 mm, 10 mm, or 20 mm, depending on inspection requirements. The transducer accommodates adjustable stroke up to 100 mm and test widths up to 80 mm, ensuring flexibility for various specimen sizes. With manual and automatic control modes, operators can tailor the inspection process to suit both routine and specialized tasks.

Durable, User-Friendly Construction

Featuring IP65 protection against water splashes, these transducers are built for resilience in harsh environments. The handheld design and clamp mounting offer convenience and precise handling. Standard BNC/Q9 shielded coaxial connectors ensure secure, noise-resistant connections, while quick-response digital displays allow real-time monitoring.

FAQs of Flaw Detector Transducers:

Q: How is a flaw detector transducer used in non-destructive testing?

A: The flaw detector transducer is employed to identify internal defects in various materials, such as steel, aluminum, alloys, and plastics. It converts electrical signals into ultrasonic waves that penetrate the specimen and reveal flaws through reflected signals, all without damaging the test material.Q: What types of probes are available, and how do they benefit users?

A: The equipment supports contact, normal, and angle beam transducers with selectable probe diameters (8 mm, 10 mm, 20 mm). This range allows users to match probe size and type to the test material, improving flaw detection accuracy and adaptability for different inspection scenarios.Q: When should the test speed and stroke be adjusted during inspection?

A: Test speed (up to 1500 mm/s) and adjustable stroke (0-100 mm) should be set according to specimen size, material properties, and required precision. Faster speeds suit larger or routine checks, while slower strokes enhance sensitivity for fine or custom analyses.Q: Where can this equipment be applied effectively?

A: The flaw detector transducer is ideal for industrial settings such as manufacturing plants, quality assurance labs, and material testing facilities across various sectors where non-destructive flaw detection is essential.Q: What is the process for connecting the transducer to the flaw detector unit?

A: Connection is straightforward: the shielded coaxial cable, equipped with a standard BNC plug, links the transducer head to the main flaw detector unit. This design ensures secure signal transmission and reduces electromagnetic interference.Q: How does the IP65 protection rating enhance the equipments durability?

A: IP65 protection ensures the transducer resists dust and water splashes, making it suitable for harsh and variable industrial environments. This prolongs operational life and maintains reliability, even under challenging conditions.Q: What are the major benefits of using this flaw detector transducer?

A: Key benefits include rapid and accurate flaw detection (1% accuracy, 0.01 mm resolution), versatility across materials and specimen sizes, and robust construction for demanding environments. The digital display and quick response time (<10 ms) also streamline quality control workflows.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NDT Equipment Category

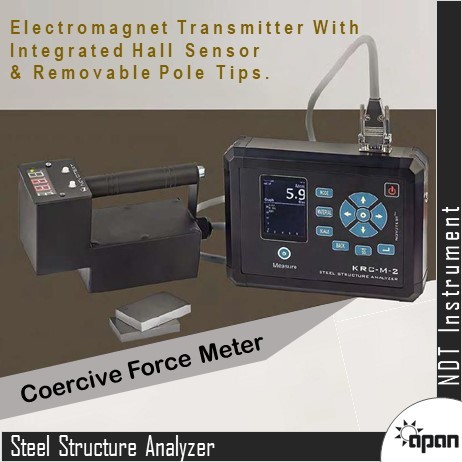

Steel Structure Analyzer

Response Time : 2 seconds

Machine Weight : 350 kg

Operating Voltage : 220V AC

Power Supply : 220V / 50Hz

Features : Data Logging, RealTime Analysis, Automatic Calculation

Humidity : 10% 85% RH

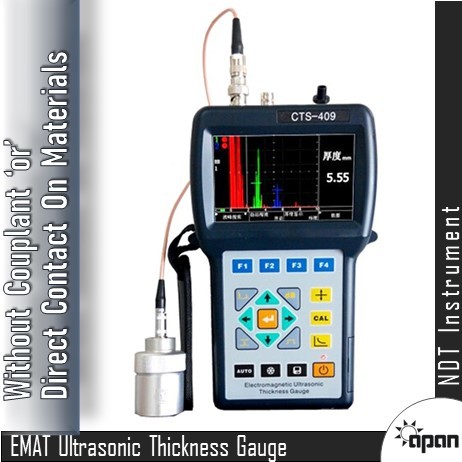

EMAT Ultrasonic Thickness Gage

Response Time : 1 second

Machine Weight : 2.7 kg

Operating Voltage : 220V AC

Power Supply : AC 220V, 50/60Hz

Features : Noncontact measurement, high penetration, suitable for rough and oxidized surfaces

Humidity : 85% RH

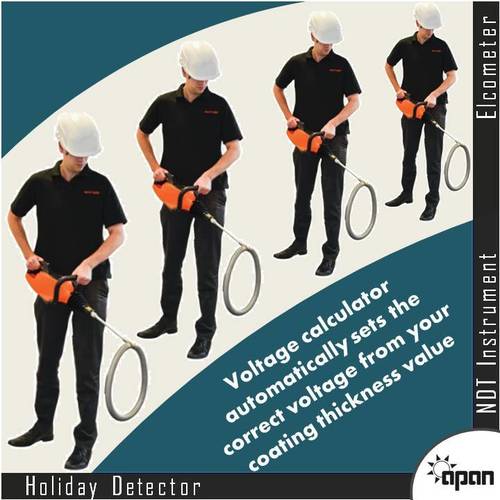

Elcometer 280 Pulsed DC Holiday Detector

Response Time : Immediate/realtime

Machine Weight : Approx. 3.4kg (7.5lb) including wand but without electrodes

Operating Voltage : 12V DC

Power Supply : Rechargeable Liion battery pack, 12V DC, 4400mAh

Features : Audible and visual alarms; adjustable pulse voltage; high voltage safety feature; external electrode compatibility

Humidity : Up to 95% RH noncondensing

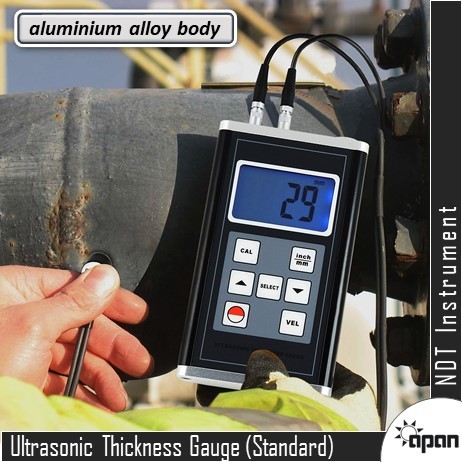

Ultrasonic Thickness Gauge (Standard)

Response Time : 0.5 seconds

Machine Weight : 200 g (approx)

Operating Voltage : 3V DC (2xAA)

Power Supply : 2 x 1.5V AA alkaline batteries

Features : Backlight display, Auto shutdown, Low battery indicator

Humidity : 85% RH

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry