Elcometer 456 Coating Thickness Gauge

Elcometer 456 Coating Thickness Gauge Specification

- Interface Type

- USB, Bluetooth (model dependent)

- Temperature

- -10C to +50C (14F to 122F)

- Accuracy

- 13% of reading (depending on probe)

- Response Time

- Instantaneous (<1 second)

- Power Supply

- 2 x AA batteries (or optional AC adapter)

- Automation Grade

- Manual

- Operating Voltage

- 3V DC (2 x AA batteries)

- Measuring Range

- Up to 1500 m (depends on probe used)

- Application

- Measuring coating thickness on metallic substrates

- Mounting Type

- Handheld

- Humidity

- Up to 95% RH, non-condensing

- Resolution

- 0.1 m or 1 m (probe dependent)

- Test Range

- 01500 m (on standard models, may vary with probe)

- Features

- Menu-driven interface, memory storage, statistics, compatible with ElcoMaster software

- Display Type

- LCD Digital Display

- Equipment Type

- Coating Thickness Gauge

- Usage

- Paint & coating inspection, quality control, industrial applications

- Machine Weight

- 185g (including batteries)

- Control Mode

- Manual

- Calibration

- Factory calibrated; user calibration supported

- Probe Types

- Integral and separate probe models available, for Ferrous (F), Non-Ferrous (N), or dual FNF substrates

- Memory Capacity

- Up to 150,000 readings (model dependent)

- Model Number

- Elcometer 456

- Statistics

- Displays mean, number of readings, standard deviation, max/min

- Backlight

- Yes, adjustable backlight

- Data Output

- USB, Bluetooth; compatible with ElcoMaster software

- Compliance

- ISO 2178, ISO 2360, ASTM B499, ASTM D7091, DIN, SSPC-PA2, AS 2331.1.4

- Dimensions

- 141 x 73 x 37 mm

- Battery Life

- Up to 24 hours continuous use

- Illuminated Display

- Yes

About Elcometer 456 Coating Thickness Gauge

As a Authorized dealer we are engaged in providing the broad assortment of Elcometer, UK make Dry Film Coating Thickness (DFT) gauge used to measure the thickness of dry film coating, this gauge is well known in worldwide.The new Elcometer 456 Coating Thickness Gauge sets new standards making measuring dry film thickness faster, reliable and accurate; helping you to become more efficient.

The Elcometer 456 is available in four different models: B, S and T. Each coating thickness gauge provides the user with increasing functionality - from the entry level Elcometer 456 B, to the top of the range Elcometer 456 T, with memory, alpha-numeric batching and Bluetooth communication.

Separate models, with their wide range of probes, provide even greater measurement flexibility.

All probes are fully interchangeable; whilst ferrous gauges accept any ferrous probe and non-ferrous gauges accept any non-ferrous probes the dual FNF gauges accept all ferrous, non-ferrous and dual FNF probes

Efficient

- Fast reading rate of 70+ per minute

- Multiple calibration memories

- Alpha numeric batch identification

- User selectable calibration methods

- Compatible with all Elcometer software including ElcoMaster 2.0

Powerful

- Wide range of interchangeable probes

- USB and Bluetooth data output

- Stores up to 75,000 readings in 999 batches

- Measures up to 30mm (1200mils) of coating on metal substrates

The new ElcoMaster 2.0 is a fast, easy to use software solution for all your reporting requirements.

Reliable

- Repeatable and reproducible

- 2 year gauge warranty

- Supplied with fully traceable test certificates

- Batch date and time stamp facility

Accurate

- Measurement Capability to 1%

- Conforms to national & international standards

- Temperature stable measurements

- Increased reading resolution for thin coatings

- Measures accurately on smooth, rough, thin and curved surfaces

Specification

| Range 1 | Scale 1 - Range: 0-1500 micron (0-60 mils) |

| Brand | Elcometer |

| Usage/Application | Ferrous,Non-Ferrous and Both/Dual |

| Display Type | Digital |

| Model Name/Number | Elcometer 456 |

| Range 5 | Scale 6 - Range: 0-31 mm (0-1220 mils) |

| Range 4 | Scale 6 - Range: 0-25 mm (0-980 mils) |

| Range 3 | Scale 3 - Range: 0-13 mm (0-500 mils) |

| Range 2 | Scale 2 - Range: 0-5000 micron (0-200 mils) |

High Precision and Adaptability

Offering a measuring range up to 1500 m and accuracy within 13%, the Elcometer 456 delivers dependable results across different coatings and metallic substrates. Changeable probes, instant response time, and adjustable resolution ensure the optimal setup for your application, whether in the field or lab.

Integrated Connectivity and Data Management

The Elcometer 456 supports both USB and Bluetooth connections, allowing easy data transfer to computers or mobile devices. Its compatibility with ElcoMaster software streamlines reporting, analysis, and integration into digital workflowsperfect for modern quality control practices.

FAQs of Elcometer 456 Coating Thickness Gauge:

Q: How do I calibrate the Elcometer 456 Coating Thickness Gauge?

A: The gauge comes factory calibrated, but users can perform their own calibrations for specific substrates using its menu-driven interface. This ensures precision tailored to the application and substrate being measured.Q: What is the process for transferring measurement data from the Elcometer 456?

A: Measurements can be transferred via USB or Bluetooth (model dependent) directly to a computer or mobile device. The gauge is compatible with ElcoMaster software, enabling efficient data management and detailed reporting.Q: When should I use an integral probe versus a separate probe model?

A: Integral probes are ideal for single-handed use and quick spot checks, while separate probes offer better access and flexibility for measuring hard-to-reach areas or curved surfaces.Q: Where can I use the Elcometer 456 for coating thickness testing?

A: Designed for industrial, laboratory, and field environments, the gauge withstands temperatures from -10C to +50C and humidity up to 95% (non-condensing), making it suitable for demanding conditions in quality control, paint inspection, and manufacturing.Q: What are the key benefits of using the Elcometer 456 Coating Thickness Gauge?

A: Benefits include rapid measurement (less than one second response), extensive memory for large projects, statistical display functions, and compliance with international standards, ensuring reliable results for critical inspection tasks.Q: How does the device display and store measurement statistics?

A: The Elcometer 456 automatically calculates and displays mean, standard deviation, number of readings, and max/min values. Depending on the model, it can store up to 150,000 readings for later review and analysis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Inspection Category

Digital Pulloff Adhesion Tester

Features : Portable, digital display, battery operated, automatic peak hold, data storage

Usage : Adhesion pulloff strength measurement

Mounting Type : Manual, handheld

Application : Paint, coating, building material, cement, concrete, surface adhesion testing

Control Mode : Digital microprocessor based

Surface Profile Gauge

Features : Corrosionresistant, easytoread dial, compact design

Usage : Surface profile measurement for quality control

Mounting Type : Handheld

Application : Measurement of blastcleaned or coated surface profile

Control Mode : Handheld

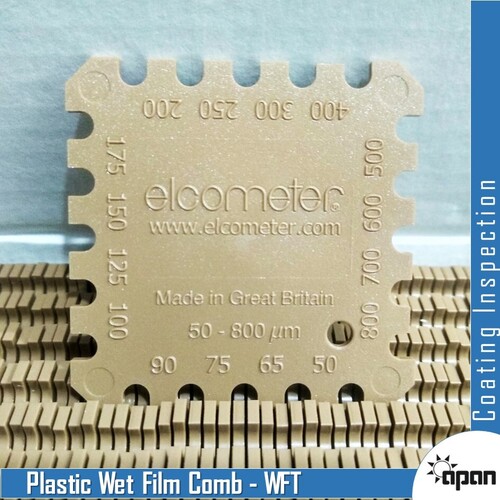

Plastic Wet Film Combs

Minimum Order Quantity : 1 Kit

Features : Corrosion resistant, lightweight, easy to use, nonreactive

Usage : Industrial, laboratory, field

Mounting Type : Handheld

Application : Measuring wet film thickness of paints, coatings and similar materials

Control Mode : Manual

Elcometer 456 Coating Thickness Gage Probe

Features : Menudriven interface, user calibration, data logging, three calibration methods, date and time stamp, measurement statistics

Usage : For industrial, automotive, and laboratory coating thickness measurement

Mounting Type : Handheld

Application : Measuring coating thickness on ferrous & nonferrous substrates

Control Mode : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry