Pin Brinell Hardness Tester

Pin Brinell Hardness Tester Specification

- Equipment Type

- Brinell Hardness Tester

- Resolution

- 0.1 HB

- Test Range

- 8-650 HBW

- Response Time

- Instantaneous

- Max Height

- 180 mm

- Features

- Portable, Robust Construction, Easy Calibration

- Specimen Size

- Pin diameter 2 mm - 10 mm

- Humidity

- 90% RH

- Frequency

- 50 Hz

- Operating Voltage

- 220V AC

- Accuracy

- 1%

- Automation Grade

- Manual

- Display Type

- Analog Gauge

- Temperature

- 10C to 40C

- Mounting Type

- Bench-Top

- Application

- Pin and small component hardness testing

- Measuring Range

- 32~650 HB

- Power Supply

- AC 220V, 50 Hz

- Number of Specimens

- Single Specimen

- Hardness

- Up to 650 HB

- Usage

- Metallurgy, Automotive, Manufacturing

- Capacity

- 3000 kgf (Max Load)

- Machine Weight

- Approx. 70 kg

- Test Speed

- Standard manual operation

- Test Width

- Max 150 mm

- Test Stroke

- 100 mm (max)

- Control Mode

- Manual

- Optical Reading Device

- Fitted microscope 20X

- Dwell Time

- 10-15 seconds

- Finishing

- Powder-coated rustproof finish

- Accessories Provided

- Set of Brinell balls & microscope

- Frame Material

- Solid Cast Iron

- Standard Conformity

- IS:1500-2/ISO 6506-2

- Indenter Type

- Hardened Steel Ball

- Test Method

- Brinell indentation method

Pin Brinell Hardness Tester Trade Information

- Main Export Market(s)

- Asia

About Pin Brinell Hardness Tester

Clients can avail this Pin Brinell Hardness Tester from us at highly competitive price. This is a unique portable instruments, integrated with a precision shear pin for ensuring correct manual loading against the sample. The Pin Brinell Hardness Tester is available for clients in a wide range of specifications and models in order to cater their diverse requirements.

Features:

- Can resist high impact

- Weather proof

- Durable quality

- At nominal price

Superior Durability and Construction

Crafted from solid cast iron and finished with a powder-coated layer, the tester is built for longevity and reliable performance, even in demanding environments. Its robust design resists rust and minimizes maintenance, translating to uninterrupted operation and consistent results across various industrial applications.

Accurate and Efficient Hardness Testing

The device utilizes a hardened steel ball indenter and a fully compliant Brinell test method, ensuring reliable measurements every time. The included 20X microscope provides clear visualization of indentations, while manual controls enable direct and straightforward operation. Calibration is easy, ensuring ongoing accuracy for every test.

Versatile Applications and Wide Test Range

Designed to accommodate single pins and small components, this tester is suited for use in metallurgy, automotive, and manufacturing sectors. Adjustable dwell times, a broad test range (32650 HB), and compatibility with a variety of sample sizes enable comprehensive material assessment for quality control and research purposes.

FAQs of Pin Brinell Hardness Tester:

Q: How does the Pin Brinell Hardness Tester operate?

A: The tester employs the Brinell indentation method, where a hardened steel ball indenter creates an impression on the specimen under a defined force. The size of the indentation is then measured using the fitted 20X optical microscope, and the hardness value is determined accordingly.Q: What components are included with the machine upon purchase?

A: Each unit is supplied with a set of Brinell balls and a 20X microscope for optical reading, ensuring you are fully equipped for immediate hardness testing.Q: Where can this tester be used effectively?

A: This tester is ideal for laboratories, quality control departments, and production environments in industries such as metallurgy, automotive, and manufacturing, especially for analyzing pins and small components.Q: What is the process for conducting a hardness test?

A: To test, place the specimen, set the dwell time (1015 seconds), manually apply the load (up to 3000 kgf), and create an indentation. Then, use the microscope to read the mark and reference the analog gauge for the final hardness value.Q: What are the benefits of using this Brinell Hardness Tester?

A: This tester provides accurate and repeatable results, is easy to calibrate, and features robust, rustproof construction. Its portability and manual control make it versatile for a wide range of applications and user-friendly for operators.Q: What is the accuracy and resolution of this device?

A: The tester offers an accuracy of 1% and a resolution of 0.1 HB, ensuring precise measurements for quality assurance and research requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Vickers Hardness Measuring System

Accuracy : 1%

Display Type : Digital LCD Display

Automation Grade : SemiAutomatic

Temperature : 10C 35C

Mounting Type : Benchtop

Usage : Metallurgical, Research Labs, Industrial Testing

Digital VickersHardness Tester

Accuracy : 1%

Display Type : Digital LCD with Backlight

Automation Grade : SemiAutomatic

Temperature : 10C 35C

Mounting Type : Tabletop

Usage : Metallurgical laboratories, research, quality control

Tablet Hardness Tester

Accuracy : 0.5 kg

Display Type : Digital/LCD

Automation Grade : Manual

Temperature : 10C35C

Mounting Type : Tabletop

Usage : Pharmaceutical laboratories

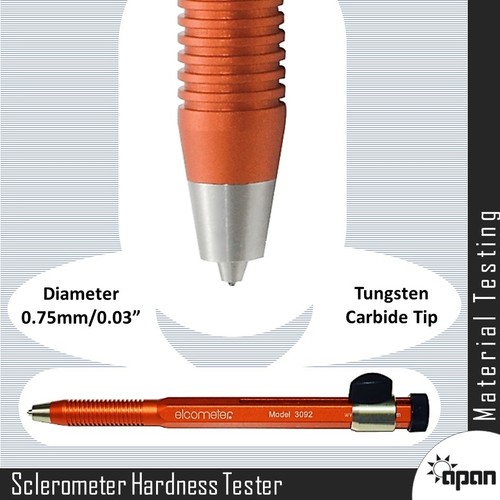

Sclerometer Hardness Tester

Accuracy : 1 HV

Display Type : Analog

Automation Grade : Manual

Temperature : 5C 40C

Mounting Type : Handheld

Usage : Surface Hardness Testing

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry