Sclerometer Hardness Tester

Sclerometer Hardness Tester Specification

- Temperature

- 5C 40C

- Automation Grade

- Manual

- Max Height

- 165mm

- Gas Pressure

- Atmospheric

- Number of Specimens

- 1

- Application

- Hardness Testers

- Humidity

- 85% RH

- Hardness

- Up to 1000 HV

- Test Range

- Up to 1000 HV

- Mounting Type

- Handheld

- Resolution

- 0.1 HV

- Features

- Portable, Durable Construction

- Specimen Size

- 165 x 24 x 16mm

- Accuracy

- 1 HV

- Measuring Range

- 0 1000 HV

- Dimension (L*W*H)

- 165 x 24 x 16mm Millimeter (mm)

- Equipment Type

- Sclerometer Hardness Tester

- Response Time

- Instant

- Display Type

- Analog

- Usage

- Surface Hardness Testing

- Capacity

- 370g

- Machine Weight

- 370g Gram (g)

- Test Speed

- Manual

- Test Width

- 24mm

- Test Stroke

- 16mm

- Control Mode

- Manual

Sclerometer Hardness Tester Trade Information

- Packaging Details

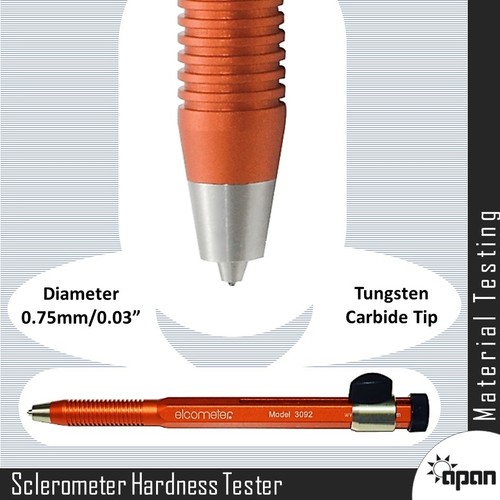

- Elcometer 3092 Sclerometer, tool with 0.75mm (0.03) diameter tungsten carbide tip, 3 springs (grey, red and blue), carry case and operating instructions

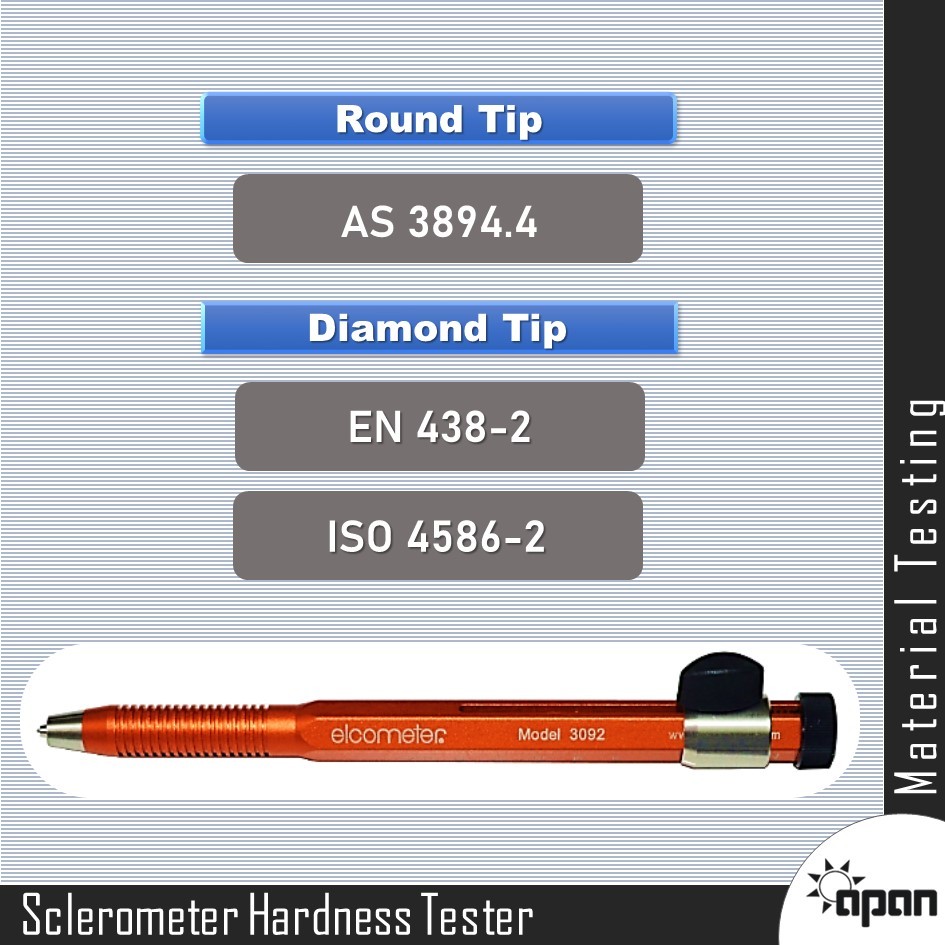

- Certifications

- AS 3894.4, EN 438-2, ISO 4586-2

About Sclerometer Hardness Tester

The Elcometer 3092 Sclerometer Hardness Tester is a simple but effective gauge for determining the hardness of a large variety of coatings and surfaces.

A tungsten carbide tip (diameter 0.75 or 1.00 mm) is moved across a surface with a preset force. The force is applied by means of a spring. By using different springs, the force can vary from 0 to 30 N. The sclerometer hardness is expressed in Newton (N) or as a classification based on the lowest pressure at which a scratch can be made.

TECHNICAL SPECIFICATION

Material : Anodised aluminium

Dimensions : 165 mm x 24 mm x 16 mm (6.5" x 1" x 0.6")

Weight : 370 g (13 oz)

SELECTING A SPRING

Four types of spring are available. The stiffness of each type is determined by its colour:

Spring colour Force applied by tip

Natural (no colour) : 0 N to 3 N

Red : 0 N to 10 N

Blue : 0 N to 20 N

Green : 0 N to 30 N

TOOLS

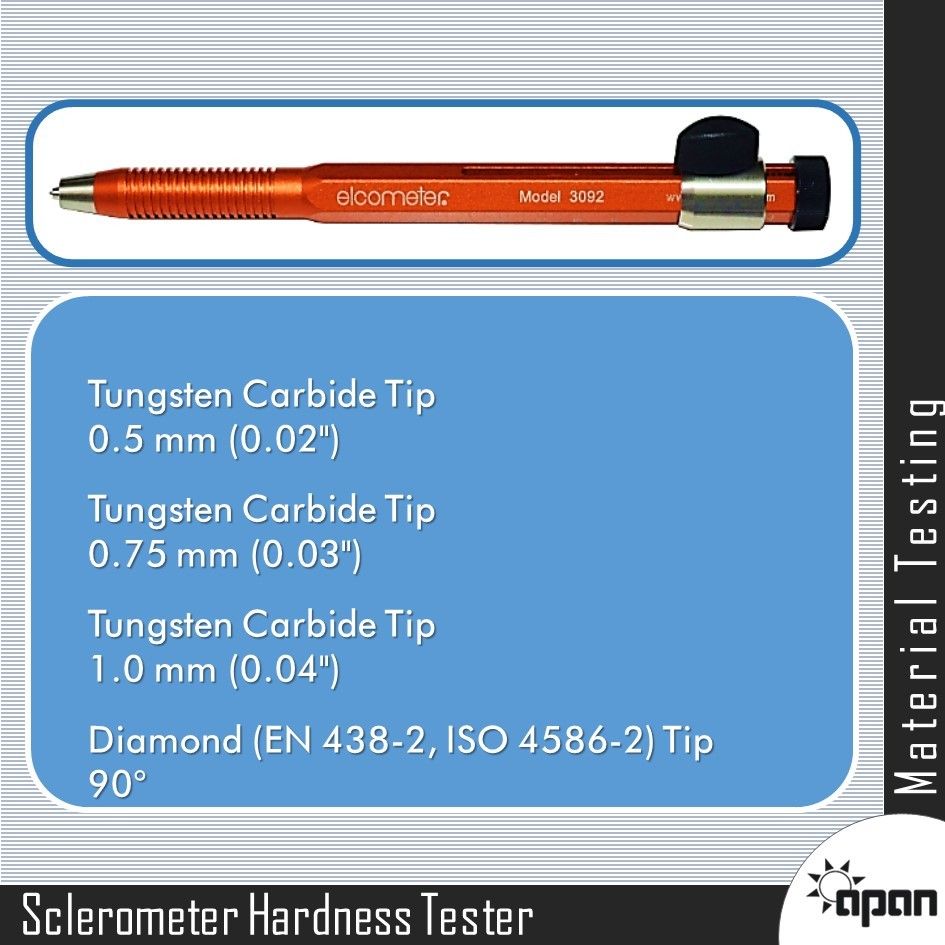

Tip Tip material Part number

0.5 mm (0.02") Tungsten Carbide Tip

0.75 mm (0.03") Tungsten Carbide Tip

1.0 mm (0.04") Tungsten Carbide Tip

90 Diamond (EN 438-2, ISO 4586-2) Tip

Elcometer 3092 Sclerometer Hardness Tester can be used in accordance with the following International Standards: Round tips AS 3894.4, Diamond tips EN 438-2 & ISO 4586-2.

Scope of supply

Elcometer 3092 Sclerometer Hardness Tester

Tool with 0.75 mm (0.03") diameter tungsten carbide tip

3 springs (natural, red and blue)

Carry case

Operating instructions

Reliable Hardness Testing for Multiple Materials

This sclerometer tester offers dependable performance across a range of materials, including metals, ceramics, and glass. Utilizing the proven scratch test method, it provides direct, instantaneous readingsenabling efficient and accurate evaluation of surface hardness in various settings, from laboratories to production lines.

Durable Design & Portability

Manufactured from hardened steel and aluminum with a polished finish, the tester ensures resilience and extended service life. Its compact, lightweight construction (370g) coupled with a protective transport case ensures that it remains portable and easy to handle during fieldwork and on-site inspections.

User-Friendly, Manual Operation

With direct analog indication and fully manual control, the tester is straightforward to operateno electricity or external power required. Its scratch marking system provides a tangible hardness measure, making it ideal for routine checks and quality assurance operations.

FAQs of Sclerometer Hardness Tester:

Q: How does the Sclerometer Hardness Tester measure the hardness of materials?

A: The tester uses the Sclerometer scratch test method to determine hardness. By scratching the sample surface (such as metals, ceramics, or glass), it provides an instant analog indication of the hardness level, measured directly in HV units up to 1000 HV.Q: What types of materials can I test with this hardness tester?

A: This instrument is designed to test the surface hardness of metals, ceramics, and glass. Its wide measuring range and sturdy construction make it suitable for diverse industrial and laboratory applications.Q: When should I use a sclerometer for my testing needs?

A: Use a sclerometer when you need a quick, reliable assessment of surface hardness, particularly for quality control, material selection, or research purposes. It is especially useful in environments where portability and manual operation are advantageous.Q: Where can this tester be efficiently used?

A: This portable, handheld tester is ideal for use in material testing labs, manufacturing environments, and on-site inspections. The included carrying case ensures it can be easily transported and used wherever surface hardness testing is required.Q: What is the process for conducting a hardness test with this device?

A: Begin by securely placing the specimen in the tester. Manually apply the sclerometer to create a scratch on the sample surface, and the hardness value will be provided instantly on the analog display. The process is straightforward and requires no additional set-up.Q: How accurate and reliable are the hardness readings?

A: The tester is factory calibrated and provides readings with an accuracy of 1 HV and a resolution of 0.1 HV. This high level of precision ensures consistent and trustworthy results for each hardness test performed.Q: What are the practical benefits of using this sclerometer tester?

A: This tester delivers immediate, accurate hardness data on a variety of materials. Its manual, portable design allows testing in the field or in the lab, while the robust, durable construction ensures longevity. It is especially beneficial for distributors, exporters, and suppliers who need reliable and versatile quality control equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Portable Hardness Tester ASTM A956

Application : Metallic material hardness measurement

Usage : Industrial/Field Hardness Testing

Machine Weight : 0.5 kg

Specimen Size : Minimum weight 0.1 kg (with support ring)

Manual Digital Rockwell Hardness Tester

Application : Hardness testing of metals and alloys

Usage : Industrial, Laboratory

Machine Weight : 80 kg

Specimen Size : Height 170 mm, Depth 135 mm

Portable Hardness Tester

Application : Onsite metal hardness testing

Usage : Metal hardness testing

Machine Weight : 1.5 kg

Specimen Size : 5 mm thickness

Pin Brinell Hardness Tester

Application : Pin and small component hardness testing

Usage : Metallurgy, Automotive, Manufacturing

Machine Weight : Approx. 70 kg

Specimen Size : Pin diameter 2 mm 10 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry