Precision Ultrasonic Thickness Gage

Precision Ultrasonic Thickness Gage Specification

- Specimen Size

- Min. 20 x 20 mm

- Features

- Auto calibration, Low battery indication, Metric/Imperial unit switch, Backlit display

- Mounting Type

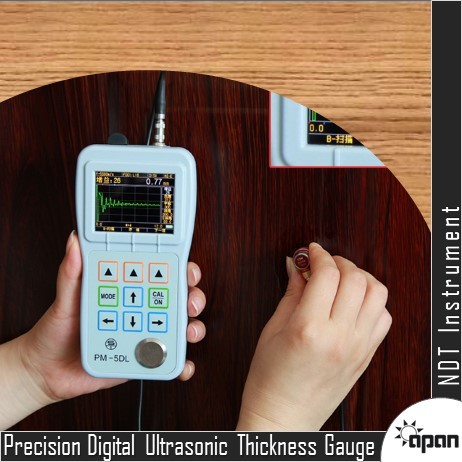

- Handheld

- Humidity

- 85% RH

- Resolution

- 0.1 mm / 0.01 mm selectable

- Application

- Thickness measurement of metals, glass, plastics, ceramics, and other ultrasonic conductors

- Equipment Type

- Precision Ultrasonic Thickness Gage

- Temperature

- -10C to 60C

- Response Time

- <0.5 second

- Frequency

- 5 MHz (standard).

- Accuracy

- (0.5%H+0.1) mm

- Test Range

- 1.0 - 200.0 mm (steel)

- Number of Specimens

- 1 at a time

- Interface Type

- Standard probe connector

- Operating Voltage

- 3V (2 x 1.5V AA batteries)

- Measuring Range

- 1.0 200.0 mm (steel)

- Automation Grade

- Manual

- Display Type

- LCD digital display (backlit)

- Power Supply

- 2 x 1.5V AA batteries

- Port Size

- Standard probe cable port

- Usage

- Industrial and laboratory measurement

- Machine Weight

- Approx. 250 g

- Test Speed

- Manual (single measurement, per second)

- Test Width

- Dependent on probe size (up to 40 mm)

- Control Mode

- Manual

Precision Ultrasonic Thickness Gage Trade Information

- Main Export Market(s)

- Asia

About Precision Ultrasonic Thickness Gage

As an Authorized dealer we are engaged in providing the broad assortment of NDT Instruments for wide range of application.

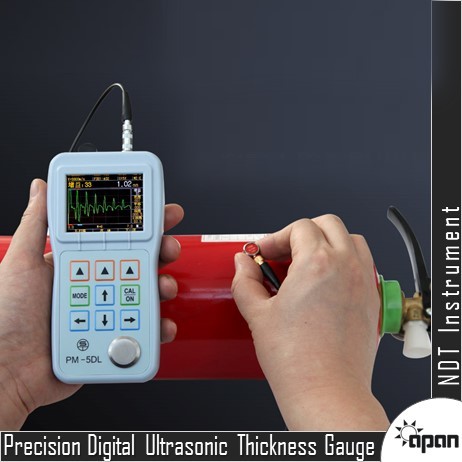

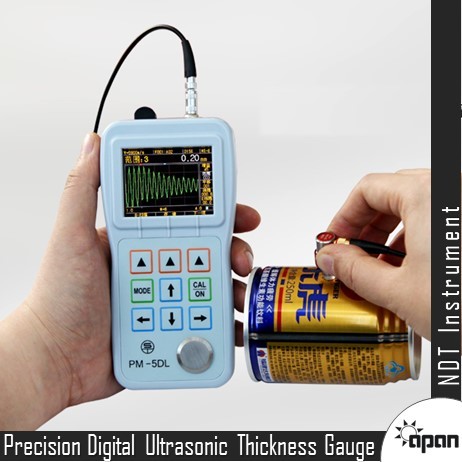

PM-5 series High precision ultrasonic thickness gauge made by our factory according to ultrasonic measuring principle, take advantage of single delay probe, transmit the ultrasonic wave from one side of the measured work-piece to the internal of the material, real-time measure the digitized thickness, without cutting the object. It is a sub-miniature measuring gauge. The features include fast response, non-destruction and precise measuring. It adopts the Multiple-wave check method to enhance the accuracy, makes the resolution reach to 0.001mm, and the lower limit as little as 0.2mm. In addition, A/B-scan waveform display is available by showing the echoes, which enables the more extensive measure range, more precise result and very little measurement error and finally makes the measuring processes more controllable.

Features :

- High precision, 0.001 mm resolution

- Real time A-Scan with adjustable gain, range, blanking etc.

- Especially fits for ultrathin work piece, can accurately and reliably measure down to 0.2 mm

- Measure through coatings, e.g. coatings on the substrate, the net thickness of the substrate can be measured without removing coatings

- Unique multiple-wave verify mode, all the thickness values have been checked through 3 to 9 times of echos, which makes the result more reliable and accurate

Specification :

- Display: 2.4QVGA(320×240)true color OLED screen, contrast 10000:1

Measuring Modes

- Interface-Echo Mode( I-E):for thick material

- Echo-Echo Mode (E-E): for the thin material and measure through the coating

- Multiple Echo Verify Mode (ME-E): All the thickness values have been checked through 3 to 9 times of echos, which makes the result more reliable and accurate

- Auto Mode: The instrument select the measuring mode automatically according to the different material being tested

Measuring Range( Steel)

- Interface-Echo Mode: 0.06''- 1.06''

- Echo-Echo Mode: 0.06''- 0.53''

- Multiple Echo Verify Mode: 0.01''- 0.35''

- Auto Mode: 0.01''-1.06''

Display Mode

- A-SCAN: Displays the whole RF echo or half-waveform after rectified

- B-SCAN: Real time B-Scan, displays the profile of the workpiece

- Big Thickness Value: The conventional display of the thickness value

- Min./Max. Capture: Display the current thickness value, Min. value and Max. value at the same time

- Difference/Thickness thinning rate: Display the difference between the real thickness value and the preset thickness value, and the percentage of the thinning value

Specification

- Gain:Real time continuously adjustable, adjustable range 41dB

- Measuring Resolution:0.0001inch

- Material Velocity Range:0.0197-0.3937in/us

- Units:Inch or Millimeter

- Language:Chinese, English, French, Germany, Japanese

- Power:2 AA size batteries, Operating time is more than 35 hours

- Working Temperature: 14°F ~122°F

- Size:6'' × 3'' ×1.5''(H ×W ×D)

- Weight: 280g including batteries

Data Recorder (Limit to PM-5DL)

- Capacity : 400 files, 100,000 thickness values and 1000 groups of waveforms

- File Structure : Grid file

- Communication : USB 2.0 Full Speed Connector

- Communication Software Data View Software

High-Precision Ultrasonic Measurement

Equipped with a state-of-the-art ultrasonic transducer, this device ensures accuracy within (0.5%H+0.1) mm and offers selectable resolutions down to 0.01 mm. Its adjustable sound velocity function is suitable for a range of ultrasonic conductive materials, making it highly versatile for industrial and laboratory scenarios.

Wide Compatibility and Application

This gage is compatible with steel, aluminum, copper, glass, plastics, ceramics, and other ultrasonic conductive materials. It is ideal for thickness measurement of pipes, plates, and various industrial or laboratory specimens. Optional probe types are available to enhance performance for different applications and material surfaces.

User-Friendly Design and Extended Battery Life

Conveniently handheld and lightweight, this gage features intuitive manual controls, automatic calibration, and a bright LCD backlit display for clear reading. Powered by two AA batteries, it delivers up to 100 hours of operation without backlight and features auto-off for optimal power saving.

FAQs of Precision Ultrasonic Thickness Gage:

Q: How does the Precision Ultrasonic Thickness Gage operate?

A: The device works by emitting ultrasonic pulses through the material using a high-precision transducer. The time it takes for the echo to return is measured, allowing the gage to accurately calculate the thickness, even for coated or curved surfaces as small as 20 mm in diameter.Q: What types of materials can I measure with this ultrasonic thickness gage?

A: You can measure the thickness of a wide variety of ultrasonic conductive materials, including steel, aluminum, copper, glass, plastics, ceramics, and more. Always ensure proper calibration and use the correct probe for optimal results.Q: When should the device be calibrated, and what calibration options does it offer?

A: It is recommended to calibrate the gage before each measurement series or whenever changing material types. The gage provides both single point and two-point calibration modes to accommodate different accuracy requirements and material properties.Q: Where can I use the Precision Ultrasonic Thickness Gage?

A: This gage is designed for both industrial and laboratory usage. It can be utilized anywhere within its specified temperature range (-10C to 60C for operation) and is suitable for fieldwork, factory inspection, or research labs.Q: What is the process for performing a thickness measurement with this device?

A: First, select and connect the appropriate probe. Apply coupling gel to the probe and the specimen surface, calibrate the device if necessary, and then press the probe against the material. The measured thickness will display instantly on the LCD screen.Q: How do I benefit from features like data hold, alarm function, and sound velocity adjustment?

A: Data hold allows you to retain a reading for easy recording. The alarm function alerts you if measurements exceed set thickness limits. Adjustable sound velocity ensures precision across different materials, maximizing measurement accuracy and flexibility.Q: What comes standard with the Precision Ultrasonic Thickness Gage, and are there optional accessories?

A: Standard accessories include an ultrasonic probe, coupling gel, carrying case, and instruction manual. You may also select from a variety of optional probes tailored for specific materials or surface conditions to further extend the devices versatility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NDT Equipment Category

Flaw Detector Transducers

Control Mode : Manual/Automatic

Application : Industrial ultrasonic flaw detection

Humidity : 85% RH

Mounting Type : Handheld, clamp optional

Features : Durable housing, high accuracy, quick response

Machine Weight : 1.5 kg

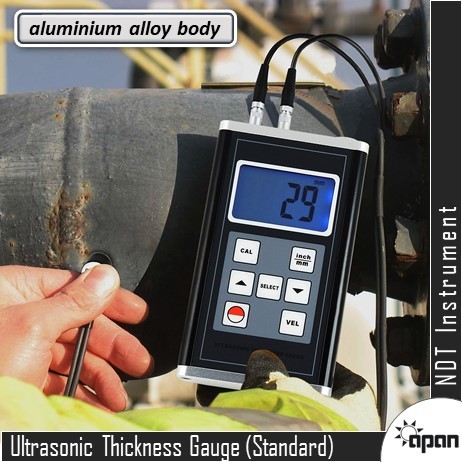

Ultrasonic Thickness Gauge (Standard)

Control Mode : Manual

Application : Thickness measurement of metal and nonmetal components

Humidity : 85% RH

Mounting Type : Handheld

Features : Backlight display, Auto shutdown, Low battery indicator

Machine Weight : 200 g (approx)

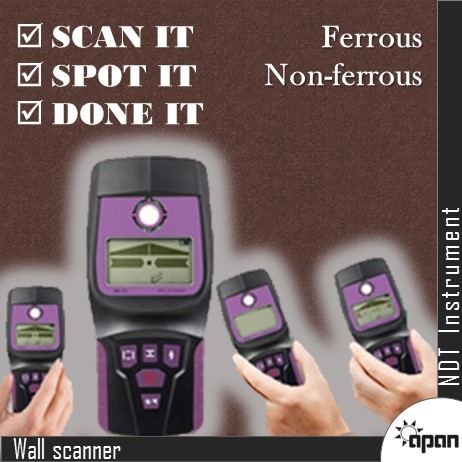

Wall Scanner

Control Mode : Push button operation

Application : Detection of metal, wood, AC wires behind wall surfaces

Humidity : Max 85% RH (noncondensing)

Mounting Type : Handheld

Features : Live wire detection, autocalibration, ergonomic grip

Machine Weight : 0.5 kg

Needle Pressure Gauge

Control Mode : Manual

Application : Industrial, Laboratory, Hydraulic and Pneumatic Systems

Humidity : 0~80% RH (Noncondensing)

Mounting Type : Panel / Direct Mount

Features : Robust construction, corrosionresistant body, clear dial with colorcoded zones, easy installation

Machine Weight : Approx. 260 g

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry