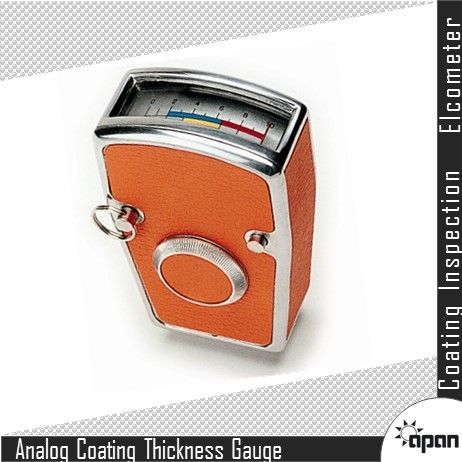

Analog Coating Thickness Meter

Analog Coating Thickness Meter Specification

- Test Range

- 0 - 1000 m (microns)

- Humidity

- 85% RH

- Number of Specimens

- Single specimen per test

- Interface Type

- Direct Probe

- Features

- Portable, Lightweight, User-friendly

- Measuring Range

- 0-1000 microns

- Resolution

- 1 m

- Specimen Size

- Minimum 30 x 30 mm

- Hardness

- Probe Tip: Hardened Steel

- Accuracy

- 2% of reading or 2 m (whichever is greater)

- Power Supply

- No Power Required (Mechanical)

- Equipment Type

- Analog Coating Thickness Meter

- Mounting Type

- Handheld

- Port Size

- Tapered Probe

- Temperature

- 0C to 40C

- Response Time

- Instantaneous

- Automation Grade

- Manual

- Display Type

- Analog Dial Gauge

- Application

- Measurement of dry film thickness on ferrous and non-ferrous substrates

- Usage

- Coating thickness measurement

- Capacity

- Varies by probe selection

- Machine Weight

- 1.5 kg

- Test Speed

- Manual

- Control Mode

- Analog

- Probe Type

- Magnetic induction and/or eddy current

- Back Cover Material

- ABS Plastic

- Display Scale

- Clearly marked analog scale with m graduation

- Probe Cable Length

- 1 meter

- Measurement Principle

- Magnetic Induction/Eddy Current

- Carrying Case

- Provided for field use

- Material Compatibility

- Works with iron, steel, aluminum, copper substrates

- Zero Adjustment

- Manual via calibration foils

Analog Coating Thickness Meter Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

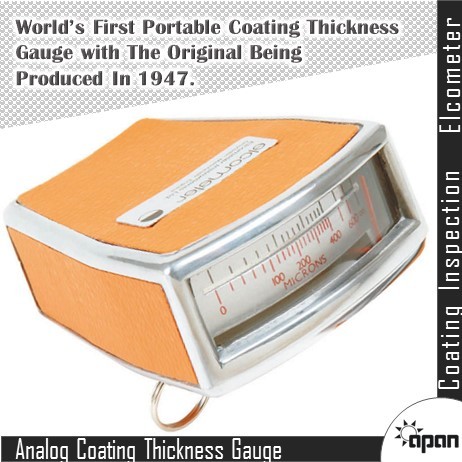

About Analog Coating Thickness Meter

As a Authorized dealer we are engaged in providing the broad assortment of Elcometer, UK make Dry Film Coating Thickness (DFT) gauge.

Mechanical Coating Thickness Gauges are suitable for working in high risk areas such as high temperature or flammable atmospheres, underwater or where the risk of explosion is high and could be triggered by the use of an electronic instrument.

From the simplest coating thickness gauge Elcometer 101 which will provide you with quick and immediate results to the more accurate coating thickness gauge Elcometer 211, also called the "banana gauge" which is ideal for cold and underwater surfaces.

Elcometer 101 was the world first portable coating thickness gauge with the original being produced in 1947. It is a mechanical coating thickness gauge for measuring nonferrous coatings or sheets to or laid on a ferrous magnetic base.

Specification :

- Range : 0 - 600m (0-25mils)

- Operating Plane : 90 to substrate

- Minimum Measurement Area : 38 x 15mm (1.5 x 0.6)

- Minimum Measurement Diameter : 25mm (1) (on bar material)

- Accuracy : 10% of the reading or 2.5m (0.1mil) which ever is the greater

Features :

- Insensitive to hot and cold surfaces - ideal for measuring coating thickness on hot sprayed metal coatings

- Incorporates reading hold feature

- Accuracy of 10%

- Ideal for hazardous areas

How to use it :

Hold the Elcometer 101 Coating Thickness Gauge at right angles to the surface to be measured, place the two contacts on the surface and push down the small button to release the pointer. When the pointer comes to rest, it will indicate the thickness of the coating. Readings can be speeded up by using the push button as a brake by pumping it in and out until the pointer comes to rest. If the component has become magnetized take an average of two readings through 180 at the same point.

Versatile Measurement Capabilities

Designed for measuring coating thickness on both ferrous and non-ferrous substrates, this meter uses magnetic induction for iron and steel, and the eddy current principle for aluminum and copper. The selectable probe accommodates a broad array of industrial applications, ensuring reliable results whether in a workshop or on site.

Reliable, Instant Readings Anywhere

With a totally mechanical operation, the analog scale provides instantaneous readings without the need for batteries or an external power supply. Its clear m graduation offers high-resolution results. The sturdy carrying case and lightweight design make transport and field work simple, while the hardened steel probe tip ensures lasting durability.

FAQs of Analog Coating Thickness Meter:

Q: How does the analog coating thickness meter measure film thickness on different substrates?

A: The meter employs magnetic induction to measure coatings on ferrous substrates like iron and steel, while the eddy current method is used for non-ferrous materials such as aluminum and copper. The probe automatically selects the appropriate measurement principle based on the material tested.Q: What is the proper process for calibrating the instrument before use?

A: Calibration is done manually using provided calibration foils. Simply adjust the zero point on the analog dial after placing the calibration foil on a standard substrate to ensure measurement accuracy before testing actual specimens.Q: When should I use this analog coating thickness meter instead of a digital one?

A: This meter is ideal when quick, reliable readings are needed without dependency on batteries or electrical power, especially in fieldwork or environments with limited access to power sources. Its analog operation also allows for immediate feedback and straightforward maintenance.Q: Where can this coating thickness meter be used?

A: It can be used both in laboratory and field environments, thanks to its portable, handheld form and rugged carrying case. It is suitable for industrial inspection, quality control, or routine testing of paint, plating, or other coatings on metal surfaces.Q: What are the benefits of using a mechanical (power-free) thickness meter?

A: A mechanical meter provides instantaneous results, requires minimal maintenance, and is immune to battery or electronic failure. Its robust construction and ease of use make it suitable for demanding working conditions and long-term operational reliability.Q: How accurate is this thickness meter, and what is its measurement range?

A: The instrument provides a measuring range of 01000 microns with an accuracy of 2% of reading or 2 m, whichever is greater. The resolution is 1 m, ensuring precise measurements for most coating applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Inspection Category

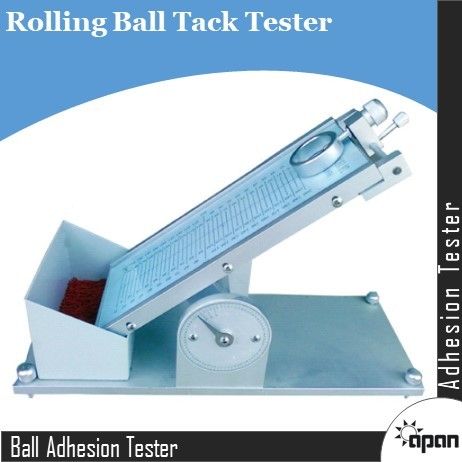

Ball Adhesion Tester

Mounting Type : Benchtop

Machine Weight : Approx. 18 kg

Temperature : Room Temperature (10C to 35C)

Control Mode : Manual & Timer controlled

Application : Adhesive tape and label adhesion testing

Usage : Ball tack/Adhesion testing

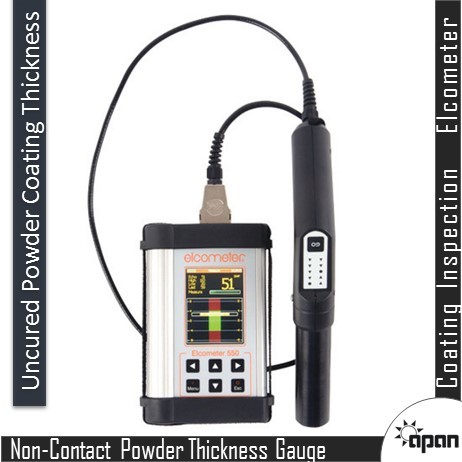

Non-Contact Powder Thickness Gauge

Mounting Type : Tabletop

Machine Weight : 22 kg

Temperature : 5C~35C

Control Mode : Automatic

Application : Powder thickness measurement

Usage : Industrial powder coating measurement

Digital Pulloff Adhesion Tester

Mounting Type : Manual, handheld

Machine Weight : 2.6 kg (approx)

Temperature : 5C~40C

Control Mode : Digital microprocessor based

Application : Paint, coating, building material, cement, concrete, surface adhesion testing

Usage : Adhesion pulloff strength measurement

Surface Profile Gauge

Mounting Type : Handheld

Machine Weight : 350 g

Temperature : 0C to 50C

Control Mode : Handheld

Application : Measurement of blastcleaned or coated surface profile

Usage : Surface profile measurement for quality control

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry