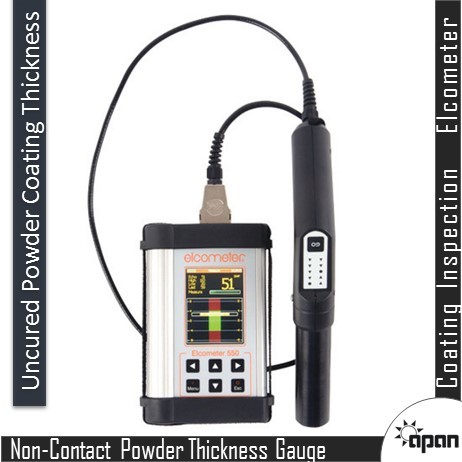

Non-Contact Powder Thickness Gauge

Non-Contact Powder Thickness Gauge Specification

- Features

- Non-contact measurement, high accuracy, digital display, fast response

- Specimen Size

- Customizable

- Number of Specimens

- 1

- Equipment Type

- Non-Contact Powder Thickness Gauge

- Operating Voltage

- 220V

- Frequency

- 50 Hz

- Test Range

- 0~5 mm

- Humidity

- ⤠80% RH

- Power Supply

- 220V/50Hz

- Port Size

- 1/2 inch

- Max Height

- 160 mm

- Display Type

- Digital LCD

- Measuring Range

- 0~5 mm

- Mounting Type

- Tabletop

- Accuracy

- ±0.01 mm

- Interface Type

- RS232

- Resolution

- 0.001 mm

- Gas Pressure

- 0.5~0.8 MPa

- Automation Grade

- Automatic

- Temperature

- 5°C~35°C

- Application

- Powder thickness measurement

- Response Time

- <1 s

- Usage

- Industrial powder coating measurement

- Capacity

- Single Specimen

- Machine Weight

- 22 kg

- Test Speed

- Up to 800 mm/min

- Test Width

- 200 mm

- Test Stroke

- 0~160 mm

- Control Mode

- Automatic

- Calibration Method

- Automatic and Manual Calibration

- Sensor Type

- Laser-based Optical Sensor

- Body Material

- Industrial Aluminum Alloy

- Storage Capacity

- Up to 1000 Measurement Records

- Data Output

- USB and RS232 Connectivity

- Protection Grade

- IP54

- Software

- Integrated Analysis and Export Tool

- Power Consumption

- 50W

- Color

- Silver Grey

- Alarm Function

- Programmable Out-of-Range Alarm

Non-Contact Powder Thickness Gauge Trade Information

- Certifications

- ASTM D7378-C

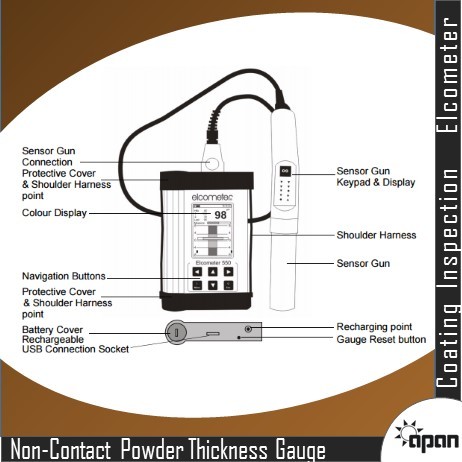

About Non-Contact Powder Thickness Gauge

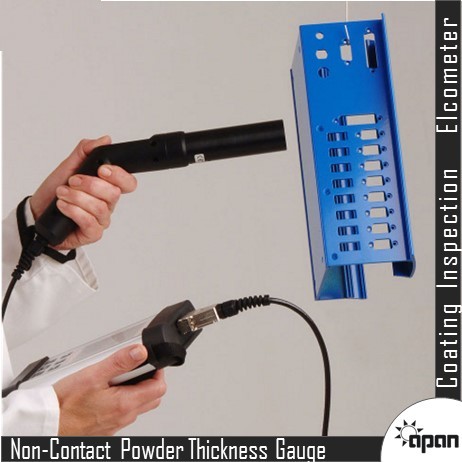

As an Authorized dealer we are engaged in providing the broad assortment of "Coating Inspection Instrument" for wide range of applications. By carefully controlling the thickness of powder applied to a product, you ca minimise your powder usage are ensure the quality of your coating.

As contact measurement solutions damage the finish and do not predict the cured coating thickness, measuring the powder thickness pre-cure requires a non-contact solution.

Using third generation proven airborne ultrasonic technology, the new Elcometer 550 accurately predicts cured coating thickness by non-contact measurement of coating powders.

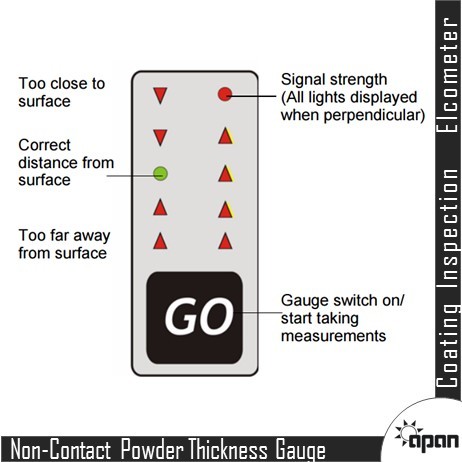

Easy to use

Reliable

Enhanced Technology

Specification

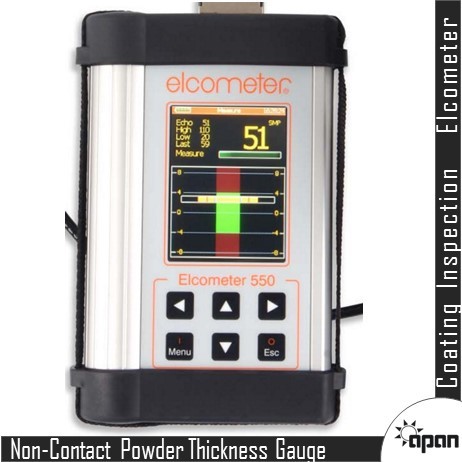

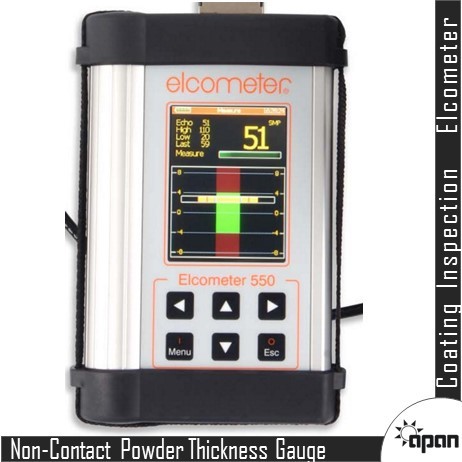

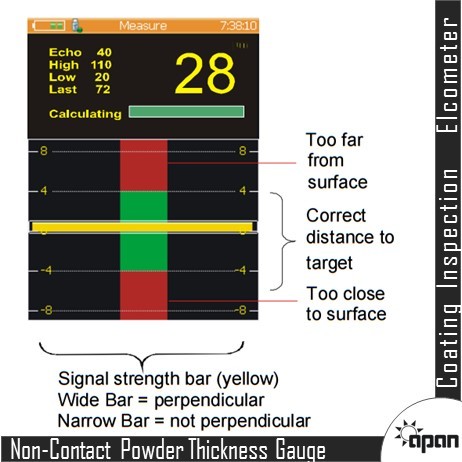

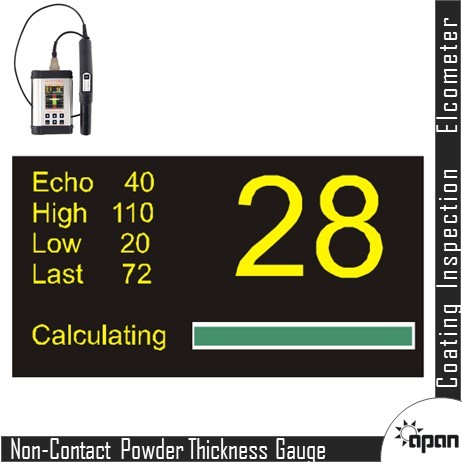

Display | 3 1/2 Inches (90mm) QVGA Colour LCD |

Power Supply | Rechargeable NIMh battery, up to 7 hours continuous use |

Measurement Range | 30 - 110um (1.18 - 4.4mils) |

Resolution | 1 um (0.04mils) |

Measurement Accuracy | +-5um (+-0.25mils) or +-5% of the coating thickness, whichever is greater |

Measurement Offset Distance | 18mm (0.71") from the coated substrate |

Measurement Area | 1m2 (0.04sq in) |

Operating Temperature Range | 10‚°C to 35‚°C (50:F to 95‚°F) |

Units | um / mils switchable |

Dimensions | 115 x 185 x 35 mm (4.6 x 7.4 x 1.4") |

Weight | 900g (1.9lbs) |

Elcometer 550 Gauge with rechargeable battery, universal charger unit and cable, sensor gun and lead, shoulder hamess, reference block, USB-PC transfer cable, carry case, test certificate and operating instructions

Advanced Laser-Based Measurement Technology

Utilizing a non-contact laser-based optical sensor, this powder thickness gauge provides rapid and highly accurate readings for powder coatings. Its advanced technology minimizes errors and supports a broad test range from 0 to 5 mm, suited for demanding industrial environments where precision is essential.

Effortless Calibration and Operation

The equipment supports both automatic and manual calibration, ensuring consistent performance and ease of use. With user-friendly controls and a digital LCD display, users can quickly view and manage results, making regular quality assessments efficient and reliable.

Robust Design for Industrial Settings

Built with premium industrial aluminum alloy and rated IP54 for dust and splash protection, the gauge guarantees durability under challenging conditions. Its programmable alarm system and efficient automatic control mode improve safety and workflow on the factory floor.

Comprehensive Data Handling and Analysis

With up to 1000 record storage capacity and integrated analysis software, users can efficiently monitor and export measurement data via USB or RS232 connectivity. The solution supports seamless integration into existing quality management systems, facilitating robust reporting and traceability.

FAQs of Non-Contact Powder Thickness Gauge:

Q: How does the non-contact laser-based sensor measure powder thickness?

A: The gauge employs a laser-based optical sensor that emits a beam onto the powder-coated surface, accurately detecting and calculating thickness without physically touching the specimen. This method ensures precise measurement while avoiding contamination or damage to coatings.Q: What calibration methods are available and when should each be used?

A: Users can choose between automatic and manual calibration. Automatic calibration is ideal for routine operations and quick setup, while manual calibration is recommended for special requirements or when calibrating for custom specimen sizes to achieve optimal accuracy.Q: Where can this gauge be used for powder thickness measurement?

A: Designed for industrial environments, the gauge is suitable for use in factories, quality control laboratories, and production lines involved in powder coating applications. Its robust construction and IP54 rating ensure reliable performance in diverse settings across India.Q: What is the process for exporting measurement records and analysis data?

A: Measurement records can be stored in the devices memory, and users can export data directly using USB or RS232 interfaces. The integrated analysis and export tool streamlines data transfer to computers for further review or reporting.Q: How do I benefit from the programmable out-of-range alarm function?

A: The programmable alarm alerts users when a measurement exceeds predefined thickness limits, helping maintain consistent product quality and prompt action if deviations occur. This feature enhances workflow efficiency and reduces the risk of faulty coatings.Q: What are the usage limits in terms of specimen size and measuring capacity?

A: The gauge is designed for single specimen measurement with customizable specimen sizes. It accommodates a test stroke up to 160 mm and a test width of 200 mm, making it adaptable to various powder coating applications.Q: What advantages does automatic control mode offer for industrial powder coating measurement?

A: Automatic control mode simplifies operation, increases testing speed (up to 800 mm/min), and reduces manual intervention. This enables consistent, repeatable measurements, saves time, and supports high-throughput industrial processes.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Inspection Category

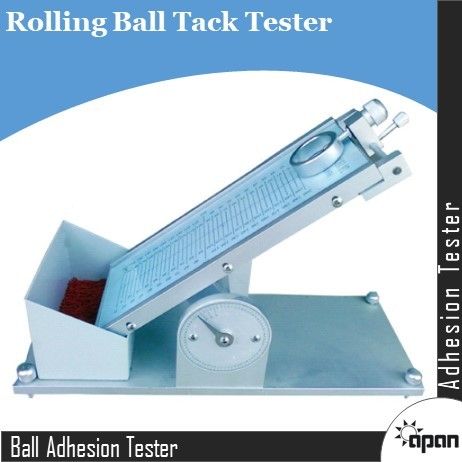

Ball Adhesion Tester

Temperature : Room Temperature (10°C to 35°C)

Automation Grade : Manual

Response Time : <2 seconds

Application : Adhesive tape and label adhesion testing

Mounting Type : Benchtop

Control Mode : Manual & Timer controlled

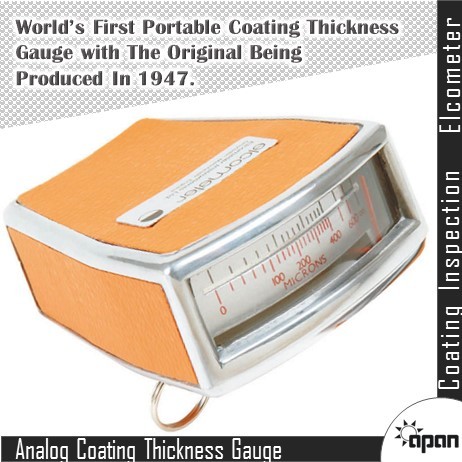

Analog Coating Thickness Meter

Temperature : 0°C to 40°C

Automation Grade : Manual

Response Time : Instantaneous

Application : Measurement of dry film thickness on ferrous and nonferrous substrates

Mounting Type : Handheld

Control Mode : Analog

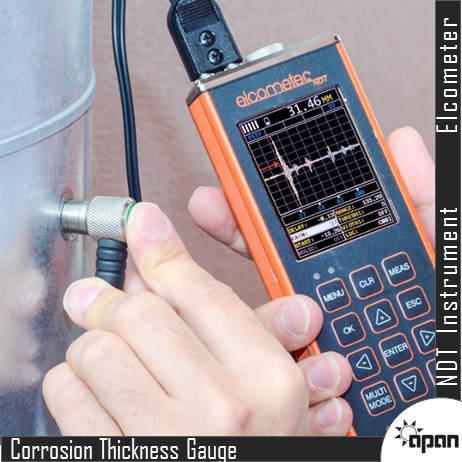

Corrosion Thickness Gauge

Temperature : 10°C to 60°C

Automation Grade : Manual

Response Time : <1 second

Application : Corrosion measurement, thickness testing of metals and other solid materials

Mounting Type : Handheld

Control Mode : Manual

Elcometer 456 Coating Thickness Gauge

Temperature : 10°C to +50°C (14°F to 122°F)

Automation Grade : Manual

Response Time : Instantaneous (<1 second)

Application : Measuring coating thickness on metallic substrates

Mounting Type : Handheld

Control Mode : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry