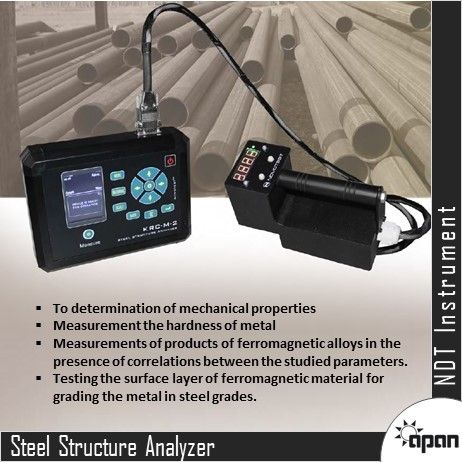

Steel Structure Analyzer

Steel Structure Analyzer Specification

- Response Time

- 2 seconds

- Operating Voltage

- 220V AC

- Mounting Type

- Bench-top

- Resolution

- 0.1 unit

- Application

- Steel Structure Testing, Quality Assurance, Research & Development

- Gas Pressure

- 0.2 - 1.0 MPa

- Test Range

- 2 kN - 300 kN

- Humidity

- 10% - 85% RH

- Port Size

- 1/2 inch

- Specimen Size

- Standard Steel Plates (customizable)

- Accuracy

- 1% F.S.

- Features

- Data Logging, Real-Time Analysis, Automatic Calculation

- Power Supply

- 220V / 50Hz

- Display Type

- LCD Digital Display

- Interface Type

- USB / RS232

- Max Height

- 800 mm

- Frequency

- 50 Hz

- Temperature

- 5C to 40C

- Hardness

- 60 HRC

- Number of Specimens

- Up to 8

- Automation Grade

- Semi-Automatic

- Measuring Range

- 0 - 9999 units

- Usage

- Industrial / Laboratory

- Capacity

- Up to 300 kN

- Machine Weight

- 350 kg

- Test Speed

- 0.1 to 500 mm/min

- Test Width

- 150 mm

- Test Stroke

- 600 mm

- Control Mode

- Automatic / Manual

- Ambient Noise Level

- 60 dB

- Cooling System

- Integrated Fan Cooling

- Frame Material

- High Strength Steel

- Safety Protection

- Emergency Stop Switch

- Data Output Format

- CSV, TXT, PDF

- Power Consumption

- 2.5 kW

- Calibration

- Automatic & Manual Options

- Motor Type

- Servo Motor

- Equipment Type

- Steel Structure Analyzer

- Software Compatibility

- Windows 7/8/10

- Color

- Metallic Grey

Steel Structure Analyzer Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Certifications

- IEC 60404-7

About Steel Structure Analyzer

As a Authorized dealer we are engaged in providing the broad assortment of wide gamut of NDT Instruments.

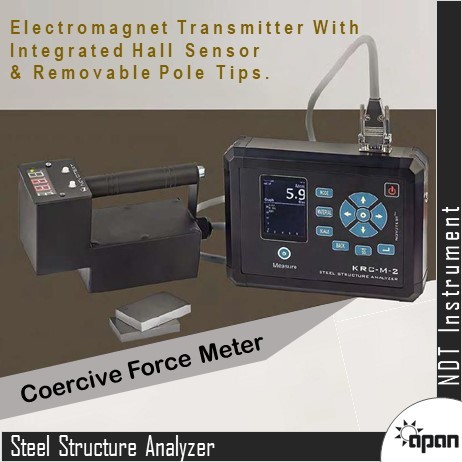

Steel Structure Analyzer is designed for measuringcoercive forceof metal products in accordance with IEC 60404-7 and is used for non-destructive testing of chemical-thermal, thermal and thermomechanical treatments, evaluation of mechanical properties and residual stresses.

Steel structure analyzer (Coercive Force Meter) is used fordetermination of mechanical properties, and measurement the hardness of metal products, as well as measurements of products offerromagnetic alloys in the presence of correlations between the studied parameters. In addition, the device is used for testing the surface layer of ferromagnetic material for grading the metal in steel grades.

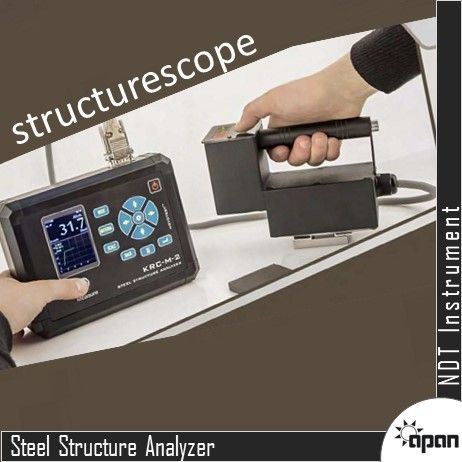

It has anelectromagnet transmitter with integrated Hall sensor andremovablepole tips.

The operation principle of the device consist offollowing: initially is performed a magnetization of area of the tested object and after that its subsequent progressive demagnetization by the increasing of the field. Next, it is the fixation of the intensity of magnetic field in accordance with the coercive force of material of tested object and measurement the amplitude of signals from the Hall sensor.

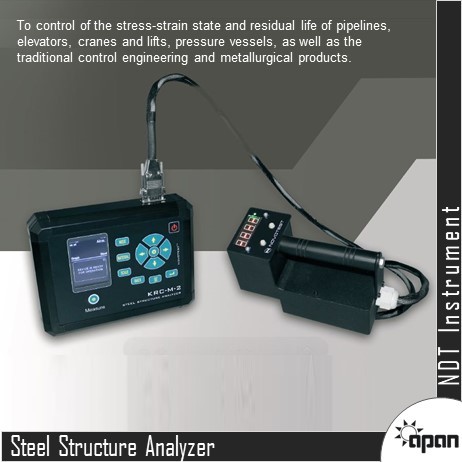

The main area of usingthe Steel Structure Analyzer is analys the stress-strain state and residual life of pipelines, elevators, cranes and lifts, pressure vessels, steel cables of bridges also it used in engineering and metallurgical industries.

- The probe with optional display and buttons control of the main functions

- Averaging 99 results, with the possibility to use the predictive average

- Memory: up to 100,000 measurements with the ability to view them on the screen of the device, or transfer to PC

- Real-time clock each measurement is saved with the date and time

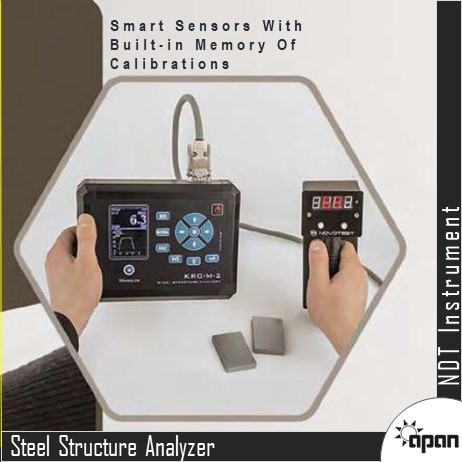

- Ability to enter additional scales and additional materials for calibration

- Calibration mode of basic and additional scales

- Adjust the brightness of the display, audio, language selection

- Ability to save backups calibrations on the internal memory of the device

- Smart sensors with built-in memory of calibrations

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Superior Build and Safety Features

Engineered from high strength steel, the Steel Structure Analyzer ensures durability and stability during intensive testing. Safety is prioritized through an emergency stop switch and integrated fan cooling, providing secure and consistent operation even in challenging environments.

Advanced Performance & Automation

Equipped with a servo motor and an automatic/manual control system, this analyzer offers flexible test speeds ranging from 0.1 to 500 mm/min. Automated calculations and options for both manual and automatic calibration simplify complex processes, improving productivity and reliability.

Comprehensive Data Management & Compatibility

Seamlessly compatible with Windows operating systems and equipped with USB/RS232 interfaces, the analyzer allows data logging and real-time analysis. Results can be exported in CSV, TXT, or PDF formats, supporting streamlined documentation for quality assurance and research activities.

FAQs of Steel Structure Analyzer:

Q: How does the Steel Structure Analyzer ensure safety during operation?

A: The analyzer is equipped with an emergency stop switch and integrated fan cooling system to protect users and equipment from any unexpected incidents or overheating during testing procedures.Q: What testing applications is this analyzer suitable for?

A: This machine is ideal for steel structure testing, quality assurance checks, and research and development in both industrial and laboratory settings. Its robust construction and versatile features support a wide range of structural evaluations.Q: When should the calibration process be performed, and what options are available?

A: Calibration can be carried out before initial use or routinely to maintain high accuracy. Users can select either automatic or manual calibration, depending on their preferences and requirements for precision.Q: Where can the Steel Structure Analyzer be installed?

A: The analyzer is designed for bench-top mounting, making it suitable for laboratories, manufacturing facilities, and quality control departments in industrial environments.Q: What is the process for testing specimens using this machine?

A: Operators mount up to 8 standard or customizable steel plates in the testing chamber, select desired test parameters, and initiate testing using either automatic or manual control modes. Data is displayed in real time and can be exported in various formats for further analysis.Q: How does the data output benefit users?

A: Data logging and real-time analysis, with results available in CSV, TXT, or PDF, facilitate efficient reporting, record-keeping, and sharing among teams, supporting streamlined quality management and research workflows.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NDT Equipment Category

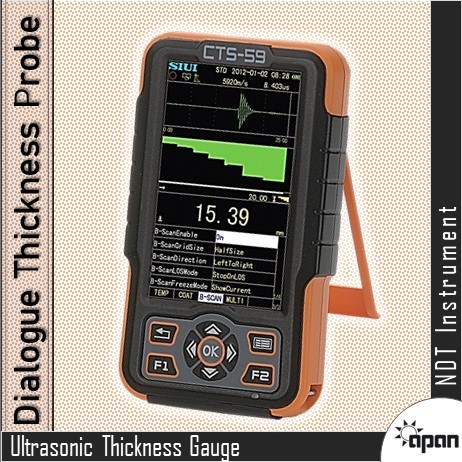

Smart Ultrasonic Thickness Gauge

Humidity : 85% RH

Control Mode : Manual

Application : Nondestructive Thickness Measurement of Metals, Pipes, and Plates

Machine Weight : 300 g

Response Time : < 1 sec

Operating Voltage : 3V

Precision Ultrasonic Thickness Gage

Humidity : 85% RH

Control Mode : Manual

Application : Thickness measurement of metals, glass, plastics, ceramics, and other ultrasonic conductors

Machine Weight : Approx. 250 g

Response Time : <0.5 second

Operating Voltage : 3V (2 x 1.5V AA batteries)

Magnetic Yoke

Humidity : Up to 85% RH

Control Mode : Handheld

Application : Magnetic particle flaw detection

Machine Weight : Approx. 3 kg

Response Time : Immediate

Operating Voltage : 230V AC

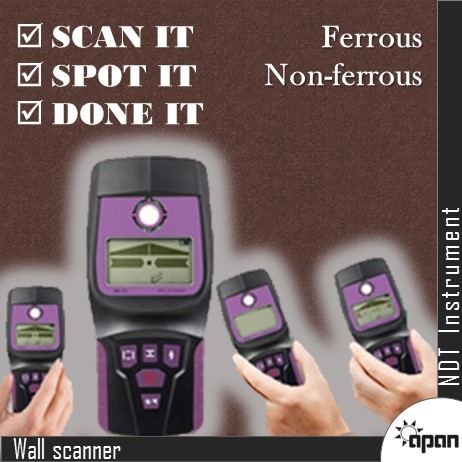

Wall Scanner

Humidity : Max 85% RH (noncondensing)

Control Mode : Push button operation

Application : Detection of metal, wood, AC wires behind wall surfaces

Machine Weight : 0.5 kg

Response Time : <1 second

Operating Voltage : 9V DC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry