Digital Rockwell & Superficial Hardness Tester

Digital Rockwell & Superficial Hardness Tester Specification

- Measuring Range

- HRB, HRC, HR15N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W

- Automation Grade

- Semi-Automatic

- Interface Type

- RS232/USB

- Test Range

- 20 - 100 HRB / 20 - 70 HRC

- Operating Voltage

- 220V

- Temperature

- 10C 35C

- Max Height

- 230 mm

- Accuracy

- 1 HR

- Resolution

- 0.1 HR

- Equipment Type

- Digital Rockwell & Superficial Hardness Tester

- Features

- Digital Display, Automatic Loading/Unloading, Memory Function

- Mounting Type

- Bench / Table Top

- Frequency

- 50Hz

- Port Size

- Standard

- Hardness

- Rockwell, Superficial Rockwell

- Display Type

- Digital LCD

- Power Supply

- 220V AC, 50Hz

- Number of Specimens

- Single Specimen Test

- Response Time

- 1 sec

- Application

- Metallurgy, Quality Control, Laboratory

- Specimen Size

- Max Height 230 mm, Depth 150 mm

- Humidity

- 85% RH

- Usage

- Hardness Testing of Metals

- Capacity

- Large Table for Various Specimens

- Machine Weight

- approx. 80 kg

- Test Speed

- Auto

- Test Width

- 150 mm

- Test Stroke

- Vertical, 150 mm

- Control Mode

- Digital

- Indenter Type

- Diamond Cone & Steel Ball

- Protection

- Overload and Overtravel Protection

- Power Consumption

- 60W

- Accessories Included

- Test Blocks, Indenter, Accessories Kit

- Result Storage

- 50 Test Results

- Loading Force

- 15kgf, 30kgf, 45kgf, 60kgf, 100kgf, 150kgf

- Preload

- 3 kgf (29.4N)

Digital Rockwell & Superficial Hardness Tester Trade Information

- Main Export Market(s)

- Asia

About Digital Rockwell & Superficial Hardness Tester

As a Authorized dealer we are engaged in providing the broad assortment of Hardness Tester for wide range of material Testing applications.

Rockwell Cum Superficial Hardness Testing Machine is manufactured under strict quality control at all manufacturing stages. This model is suitable for testing hardness of metals and alloys of all kinds, hard or soft, whether flat or round etc. or of irregular shape. This model is having superior design to that of existing conventional Rockwell Hardness Testers &easy to operate still quite sensitive &accurate.

FEATURES :

- Machine is having different Taper front look and superior aesthetic look over conventional Rockwell Hardness Tester.

- Unidirectional Big Dial type auto load selection knob for load selection of loads 15,30,45,60,100 & 150 kgf.

- Most of the important parts are plated to avoid rusting.

- An antifriction linear bearing is fixed in Hardened & ground bush which will provide perfect vertical movement of diamond holder. Thus the testing of small pin or ball up to 3mm dia is possible.

- All models conform to - IS : 1586, BS 10109-2, ASTM-E-18 & ISO : 6508-2 for Rockwell & Superficial Test.

SALIENT FEATURES :

- LCD Graphical Display with 128 x 64 pixels & Results are displayed in BIG Font size

- Minor load is graphically displayed on LCD screen (Minor load auto brake system)

- Provision of Numbers. of tests, mean, standard deviation, maximum, minimum range, individual test hardness numbers in PC Software.

- Dwell Time setting for MAJOR Load 1 to 99 sec & MINOR load dwell time is 1-30 sec.

- 75 Results are stored in the system with automatic result data storage.

- User can enable auto save results storage in system or disable it.

- User can select appreciate scale according to weight selected.

- Motorized Automatic Loading or Manual Loading is selectable.

- Conversion of results from Rockwell to Brinell (HB) , Vickers (HV), Knoop (HK), Tensile Strength (KSI),

- Serial Port for Dot Matrix Printer or EPSON LX 300 +.

- Print result consists of Serial No. Hardness Value and Hardness Scale

Specification

Test Loads (Kgf) | 15,30,45,60,100,150 |

Initial Loads (Kgf) | 3 kgf. for superficial test 10 kgf. for Rockwell |

Max. Test Height (mm) | 220 |

Depth of Throat (mm) | 130 |

Size of Base (mm) | 600 x 200 (Approx.) |

Machine Height (mm) | 850 |

Net Weight (Approx.) kg. | 90 Kg. |

Supply | AC220V |

Precision and Versatility in Hardness Measurement

This digital hardness tester utilizes both diamond cone and steel ball indenters to deliver accurate Rockwell and Superficial Rockwell hardness values across multiple scales (HRB, HRC, HR15N/T/W, HR30T/W, HR45T/W). Its high-resolution LCD display and automated loading/unloading streamline the testing process for consistent and repeatable results.

Robust Design and User-Focused Operation

Equipped with overload and overtravel protection, this tester ensures the safety of both operator and equipment. The large worktable and test width accommodate various specimen sizes, enabling flexible use in diverse laboratory and industrial environments. The included accessories kit supports immediate use and maintenance.

FAQs of Digital Rockwell & Superficial Hardness Tester:

Q: How does the Digital Rockwell & Superficial Hardness Tester operate for different hardness scales?

A: The tester utilizes diamond cone and steel ball indenters along with selectable loading forces (15kgf-150kgf), automatically applying the appropriate load and measuring the hardness on Rockwell (HRB, HRC) and Superficial (HR15N/T/W, HR30T/W, HR45T/W) scales, all controlled via the digital interface.Q: What types of specimens and maximum sizes can be tested with this machine?

A: Single specimen tests are supported, with a maximum height of 230 mm and depth of 150 mm, making it suitable for a wide range of metal samples commonly found in metallurgy labs and quality control settings.Q: When is it beneficial to use the digital memory and result storage feature?

A: The memory function, which stores up to 50 test results, proves useful for batch testing, data tracking, and maintaining records for quality assurance or further analysis in laboratory and industrial applications.Q: Where can the tester be installed and operated effectively?

A: With its bench/table top mounting design and manageable 80 kg weight, the tester is well suited for use in laboratories, workshops, and production facilities. It requires a 220V AC, 50Hz power supply for operation.Q: What is the process for conducting a hardness test using this equipment?

A: Place the prepared specimen on the large table, select the desired test scale and load digitally, and let the machine automatically apply the force and perform the measurement. Results are shown on the LCD display within one second.Q: How does the overload and overtravel protection benefit the operator?

A: These safety features prevent machine damage and ensure test accuracy by protecting the tester and specimen from excessive force or movement during use, adding reliability and extending equipment lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Vickers Hardness Measuring System

Accuracy : 1%

Resolution : 0.01 HV

Mounting Type : Benchtop

Features : Automatic measuring, data storage, precise measurement

Hardness : Vickers (HV)

Number of Specimens : Single Specimen

Portable Hardness Tester

Accuracy : 4 HL (0.5% at 800 HL)

Resolution : 1 HL

Mounting Type : Handheld

Features : Memory function, backlit display

Hardness : Can measure HL, HB, HV, HRC, HRB, HRA, HS

Number of Specimens : 1 at a time

Pin Brinell Hardness Tester

Accuracy : 1%

Resolution : 0.1 HB

Mounting Type : BenchTop

Features : Portable, Robust Construction, Easy Calibration

Hardness : Up to 650 HB

Number of Specimens : Single Specimen

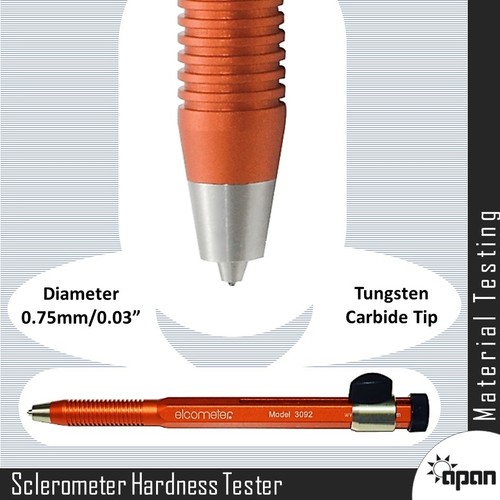

Sclerometer Hardness Tester

Accuracy : 1 HV

Resolution : 0.1 HV

Mounting Type : Handheld

Features : Portable, Durable Construction

Hardness : Up to 1000 HV

Number of Specimens : 1

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry