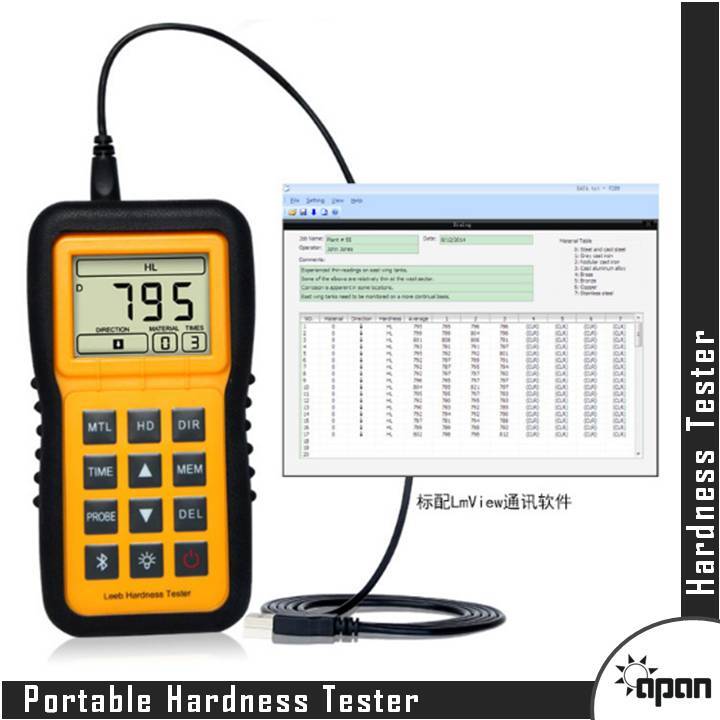

Portable Hardness Tester

Product Details:

Product Description

As a Authorized dealer we are engaged in providing the broad assortment of "Hardness Tester" includes table top and Portable type. provides not only accurate, reliable and repeatable hardness test readings, but also compact, comfortable and durable structure with rubber case for the best protection of the unit. Furthermore, by its most-recent high-tech related features like Bluetooth interface, 800 data storage capacity, large and sharp high contract LCD display, as well as easy and resourceful menu operation.

The impact body, which is equipped with tungsten carbide, impact velocities are measured at the 1mm point from the work piece in the following way:

the integrated permanent magnet will produce directly proportional voltage with the impact velocity.

The Leeb hardness values are calculated by the following formula: HL=1000X(Vb/Va)

Specification

Measuring Method | Leeb Hardness method |

Hardness Scale | HL, HB, HRB, HRC, HV, HS, b |

Measuring Range | HLD(200-960), HRC(19.8-68.5), HRB(13.5-100), HB(30-651), HV(80-976), HS(26.4-99.5), b(375-2639)

|

Impact Device | D type impact device standard, optional C / G / DC / DL / D+15 |

Accuracy | 6HLD (HLD=800), Repeatability:less 6HLD (HLD=800) |

Measuring Direction | 360 degree by manual setting |

Material | Steel& Cast Steel, Stainless Steel, GC iron, NC iron, Cast Aluminum alloy, Macht metal, Copper-tin alloy, Brass. |

Resolution | 1HL, 1HV, 1HB, 0.1HRB, 0.1HRC, 0.1HS |

Display | High Contrast Segment Liquid Crystal Display (LED Backlight) |

Data Memory | 100 groups (each group include 1-7 testing result and 1 MEAN value) |

Communication | USB port (Standard) and Blue tooth (Optional) |

Printer | Thermal Printer with blue tooth (optional) |

Power | 2 AA batteries |

Working Temperature | -10 to +50 |

Size | 153 x 76 x 37 (mm) |

Weight | 280g include batteries |

Standard | GB/T 17394-1998, ASTM A956 |

Other Products in 'Material Testing' category

|

APAN ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry