Duct Deposit Measuring System

Duct Deposit Measuring System Specification

- Frequency

- 50 Hz

- Resolution

- 0.01 mm

- Mounting Type

- Handheld or tripod mount

- Specimen Size

- Up to 100 x 100 mm

- Port Size

- DN100 (customizable)

- Temperature

- 10C - 60C

- Number of Specimens

- Single or multiple

- Measuring Range

- 0 - 10000 g/cm

- Test Range

- 0 - 10 mm (deposit thickness)

- Equipment Type

- Portable Duct Deposit Measuring System

- Interface Type

- USB and RS232

- Automation Grade

- Semi-automatic

- Response Time

- <2 seconds

- Display Type

- LCD digital display

- Operating Voltage

- 220V

- Application

- Measurement of dust, grease or particulate deposit in air ducts

- Accuracy

- 2%

- Humidity

- 10% - 95% RH

- Max Height

- 150 mm (sensor clearance)

- Gas Pressure

- 0.2 - 0.5 MPa

- Power Supply

- 220V AC, 50Hz

- Features

- Portable, high precision, easy calibration, real-time data output

- Usage

- HVAC, industrial duct cleanliness verification

- Capacity

- Up to 5 samples per cycle

- Machine Weight

- 18 kg

- Test Speed

- 0.1 - 2 m/s adjustable

- Test Width

- 100 mm

- Test Stroke

- 300 mm

- Control Mode

- Digital microprocessor based

- Data Output Format

- CSV, TXT

- Alarm Indication

- Audio-visual buzzer warning for out-of-range

- Surface Type

- Compatible with metal and flexible ducts

- Calibration Method

- Auto and manual calibration support

- Sensor Type

- Capacitive, non-contact

- Ambient Noise Level

- Less than 65 dB

- Operating Environment

- Indoor/Outdoor

- Data Storage Capacity

- Up to 10,000 test records

Duct Deposit Measuring System Trade Information

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

About Duct Deposit Measuring System

Features

- As a Authorized dealer we are engaged in providing the broad assortment of Elcometer Digital Inspection Kits.

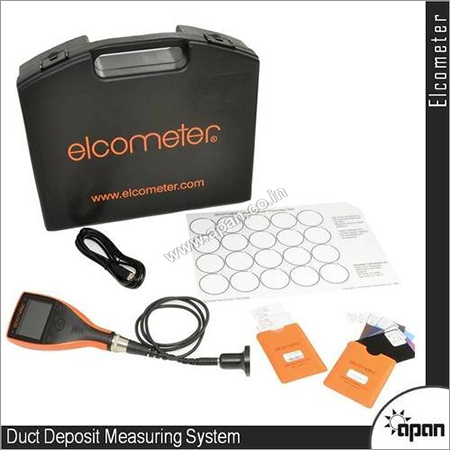

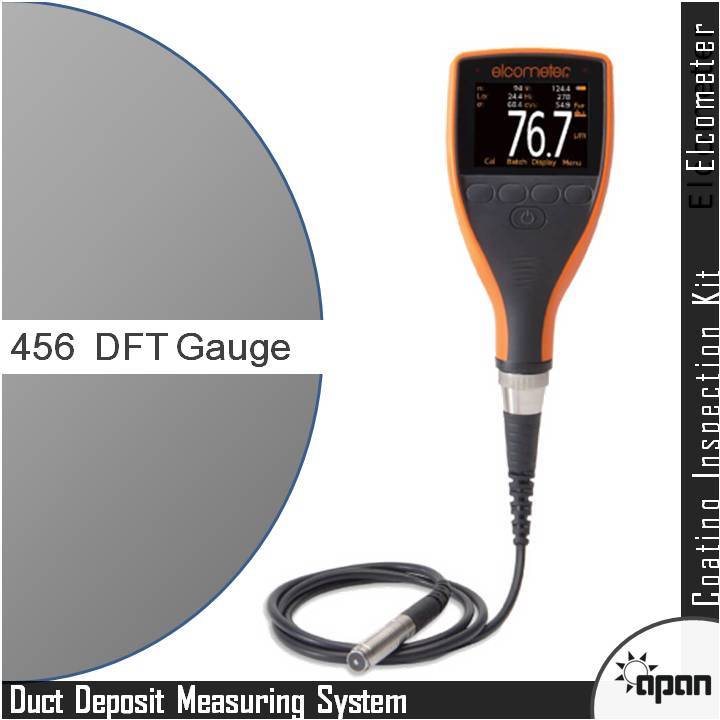

- Elcometer Duct Deposit Measuring System

- Controlling ducting deposits and monitoring their build-up is essential to maintain hygiene standards and reduce fire risks in heating and ventilation systems.

- The Elcometer 456 Duct Deposit Measuring System has been specifically designed to meet the requirements of the DTT (Deposit Thickness Test) in HVCAs (Heating & Ventilation Contractors Association) Guide to Good Practice, for the measurement of dust and grease deposits within ventilation systems and kitchen ducts made of ferrous metals.

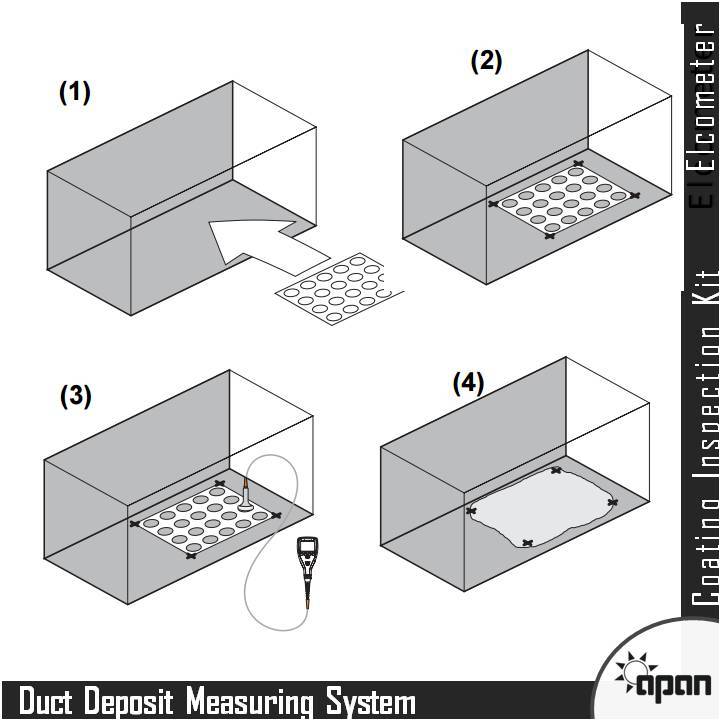

- By using the Elcometer 456 Ferrous Top Gauge with the specially designed probe and duct cleaning templates, readings can be taken of the deposit thickness on a specific test area, before and after cleaning.

- Elco Master software, supplied as standard with the Elcometer 456 Duct Deposit Measuring System includes a template designed specifically for reporting duct deposit measurements.

Advanced Measurement Technology

Equipped with a reliable capacitive, non-contact sensor, this measuring system delivers accurate and repeatable measurements for duct cleanliness verification. Its digital microprocessor control guarantees streamlined operations and enhanced performance in diverse industrial settings.

Flexible Data Management

The system provides ample storage for up to 10,000 test records, supporting both CSV and TXT export through USB or RS232 interfaces. Real-time data output enables efficient tracking and analysis, making record-keeping simple and comprehensive.

User-Friendly Operation and Safety

Featuring auto and manual calibration, LCD digital display, and an intuitive interface, this system is easy to operate. Audio-visual buzzers alert users instantly to out-of-range results, enhancing safety protocols and operational confidence.

FAQs of Duct Deposit Measuring System:

Q: How does the Duct Deposit Measuring System ensure accurate deposit measurement?

A: The system employs a high-precision capacitive, non-contact sensor with a resolution of 0.01 mm and accuracy of 2%. It is designed to measure particulate deposits in both metal and flexible ducts efficiently, even across a wide environmental range.Q: What is the data storage and export capacity of this measuring system?

A: It can store up to 10,000 test records internally and supports data output in CSV or TXT formats through USB and RS232 interfaces, allowing easy archive and analysis.Q: When should the device be calibrated and what options are available?

A: Calibration should be performed periodically or when prompted for optimal accuracy. The device offers both automatic and manual calibration modes to suit varied operational preferences or regulatory requirements.Q: Where can this duct measuring system be used?

A: Thanks to its rugged design, this system operates reliably in both indoor and outdoor environments across a temperature range of 10C to 60C and can withstand humidity of 10% to 95% RH, making it ideal for HVAC and various industrial applications in India.Q: What is the process for measuring duct deposits using this system?

A: Simply mount the sensoreither handheld or on a tripodover the duct area to be tested, initiate the measurement via the digital control interface, and review real-time data on the LCD. The fast response time (<2 seconds) and automated alarms expedite the process.Q: What advantages does this system offer for duct cleanliness verification?

A: Operators benefit from portability, adjustable test speeds, compatibility with diverse duct types, and rapid data collection. Its SEMI-automatic operation, extensive storage, and real-time output streamline compliance and cleanliness verification procedures effectively.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Elcometer Category

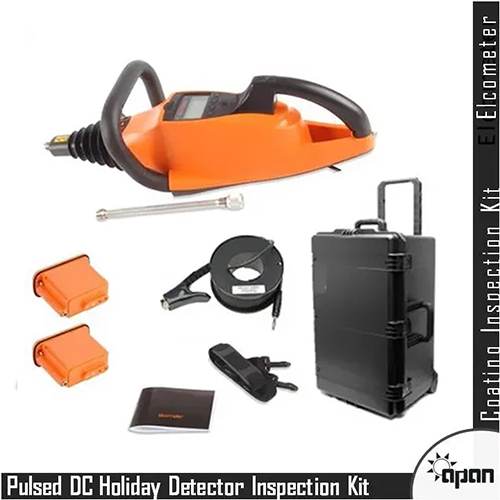

Holiday Detector Inspection Kit

Features : Lightweight, adjustable voltage, audible and visual alarm, interchangeable probes

Application : Detecting pinholes, holidays and porosity in coatings

Automation Grade : Manual

Usage : Field and laboratory coating inspection

Humidity : 090% (noncondensing)

Accuracy : 1% of full scale

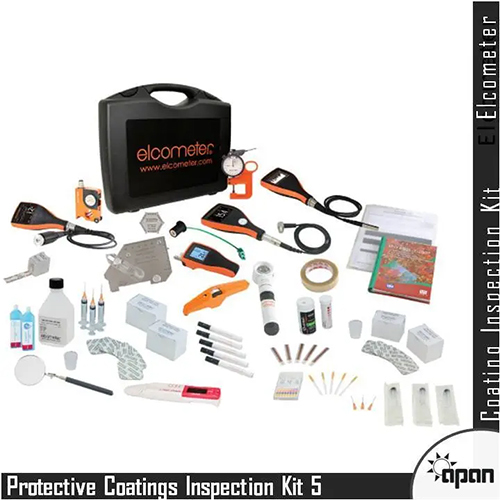

Elcometer Protective Coating Inspection Kit 5

Features : Comprehensive kit, portable case, multitool inspection

Application : Coating inspection (surface profile, dry film thickness, climatic conditions, adhesion)

Automation Grade : Manual

Usage : Field and laboratory inspection

Humidity : 0100% RH (using digital hyrometer)

Accuracy : 2% for DFT gauge, 3% for thermometer/hygrometer

Elcometer Blasting Inspection Kit 2

Features : Complete kit for onsite blasting inspection, portable carry case, includes profile gauge, replica tape, dust test kit, salt contamination kit, thermometer, hygrometer

Application : Surface profile, cleanliness, dust, and environmental condition assessment

Automation Grade : Manual

Usage : Blasting and painting surface preparation inspection

Humidity : Operating: 0%95% (noncondensing)

Accuracy : As per instrument; profile gauge 5 m

Elcometer Blasting Inspection Kit

Features : Comprehensive Kit for Surface Profile, Blast Cleaning & Dust Assessment

Application : Surface Preparation and Blasting Inspection

Automation Grade : Manual

Usage : Onsite Inspection and Measurement

Humidity : 10% to 90% RH (Non Condensing)

Accuracy : 1% (Individual Instruments)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry