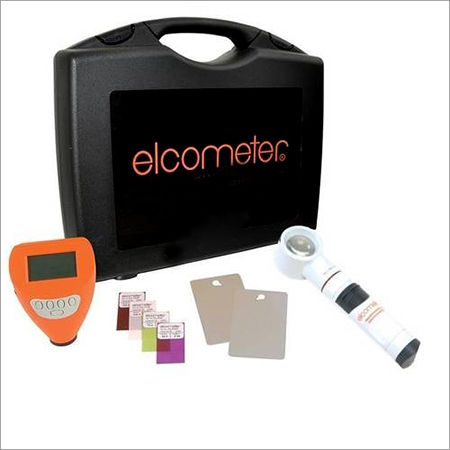

Elcometer Blasting Inspection Kit

Elcometer Blasting Inspection Kit Specification

- Test Range

- Visual Inspection Range

- Automation Grade

- Manual

- Specimen Size

- Varied (Depends on Inspection Surface)

- Mounting Type

- Portable

- Features

- Comprehensive Kit for Surface Profile, Blast Cleaning & Dust Assessment

- Equipment Type

- Blasting Inspection Kit

- Accuracy

- 1% (Individual Instruments)

- Resolution

- 1 m

- Operating Voltage

- N/A (Mechanical)

- Power Supply

- N/A (Mechanical and Non-powered Equipment)

- Measuring Range

- 0 to 1000 m (Depending on Instrument Included)

- Display Type

- Analog / Digital (varies by tool)

- Humidity

- 10% to 90% RH (Non Condensing)

- Temperature

- -10C to 50C Operating Range

- Response Time

- Instantaneous (Depends on Gauge/Instrument)

- Application

- Surface Preparation and Blasting Inspection

- Usage

- Onsite Inspection and Measurement

- Machine Weight

- 3.2 kg (Including Carry Case)

- Control Mode

- Manual

- Inspection Mirror Size

- Approx. 60 mm Diameter

- Dust Tape Test

- Compatible with ISO 8502-3

- Reference Comparator

- ISO 8503-1 Grit & Shot profiles

- Surface Profile Gauge Range

- 0 to 500 µm

- Magnifier Loupe Magnification

- x10

- Corrosion Resistance

- Yes

- Profile Gauge Type

- Digital or Mechanical

- Compliance Standards

- ISO 8502, ISO 8503, ASTM D4417

- Kit Contents

- Surface Profile Gauge, ISO Dust Test Kit, Blast Cleanliness Assessment Reference, Magnifier Loupe, Inspection Mirror, Carry Case

- Environment

- Outdoor & Indoor Use

- Carry Case Dimensions

- 320 x 270 x 110 mm

Elcometer Blasting Inspection Kit Trade Information

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

About Elcometer Blasting Inspection Kit

The Elcometer Blasting Inspection Kit is a surface preparation inspection kit providing a range of inspection equipment to test surface profile and surface contamination of blasted profiles.

An Elcometer 456 Gauge and probe can also be supplied. (Order separately if required).

Measurement parameters include:

- Surface assessment

- Blast equipment inspection

- Surface profile

- Surface contamination

Model | Description |

Elcometer 128 | Pictorial Standards1 |

Elcometer 102 | Needle Pressure Gauge |

Elcometer 103 | Blast Nozzle Gauge |

Elcometer 125 | Surface Comparator, Grit |

Elcometer 125 | Surface Comparator, Shot |

Elcometer 122 | Testex Tape, Coarse |

Elcometer 122 | Testex Tape, Extra Coarse |

Elcometer 124 | Testex Dial Thickness Gauge |

Elcometer 224 | Surface Profile Separate Gauge, Model T |

Elcometer 224 | Standard Separate Probe |

Elcometer 142 | Dust Tape Test Kit |

Elcometer 134 | Chlor Test Surface Testing Kit |

Elcometer 134 | Chlor Test Abrasive Testing Kit |

Elcometer 134 | Chlor Test Water Testing Kit |

Elcometer 138 | Bresle Salt Kit2 |

Elcometer 138/2 | Surface Contamination Kit |

ElcoMaster® | Data Management Software & USB Cable |

Swedish Rust Standard ISO 8501, SIS055900 supplied in Metric Kit

US Standard SSPC VIS 1-01 and VIS-3 supplied in Imperial Kit Supplied with Elcometer 135C Bresle Test Patches (x50)

Comprehensive Blasting Surface Inspection

This kit combines all the essential tools needed for effective surface preparation and blasting inspection. With versatile gauges, visual aids, and reference standards, professionals can accurately evaluate surface roughness, cleanliness, and contamination levels onsite. It ensures process compliance and quality control in various industrial applications.

Ready for Challenging Environments

Engineered for both indoor and outdoor use, the kit components withstand a humidity range of 10% to 90% RH and temperatures from -10C to 50C. Its portable carry case makes transportation easy, and the corrosion-resistant materials assure durability in harsh conditions, supporting reliable inspection results every time.

FAQs of Elcometer Blasting Inspection Kit:

Q: How does the Elcometer Blasting Inspection Kit help with surface preparation assessment?

A: The kit includes instruments to measure surface profile, check dust levels, and evaluate blast cleanliness, ensuring that surfaces meet industry standards (ISO 8502, ISO 8503, ASTM D4417) before coatings are applied. This promotes optimal adhesion and long-term durability of protective layers.Q: What are the main contents of the Elcometer Blasting Inspection Kit and their functions?

A: The kit contains a surface profile gauge (digital or mechanical) for measuring roughness, an ISO dust test kit to identify dust contamination, blast cleanliness reference for visual comparison, a x10 magnifier loupe, a 60 mm inspection mirror, and a durable carry case for mobility and protection.Q: When should the blasting inspection kit be used during the surface preparation process?

A: It is best used after abrasive blasting but before the application of paints or coatings. This timing enables users to confirm that the required cleanliness and profile have been achieved, directly impacting the quality and longevity of surface treatments.Q: Where can the Elcometer Blasting Inspection Kit be effectively utilized?

A: The kit is suitable for both outdoor and indoor environmentsindustries ranging from shipbuilding, construction, and metal fabrication to maintenance operations. Its portability and manual operation make it ideal for onsite inspections and varied workplace settings.Q: What is the process for using the dust tape test included in the kit?

A: To perform a dust tape test, a special adhesive tape is pressed onto the blasted surface, then removed and compared against ISO 8502-3 standards using the reference comparator and magnifier loupe. This assessment helps determine if the surface cleanliness level is adequate for coating application.Q: How does using this kit benefit inspection teams and their organizations?

A: By providing comprehensive measurement and assessment tools, the kit enables teams to ensure compliance with international standards, reduce risk of coating failures, and enhance productivity through rapid, reliable inspections. This ultimately improves quality assurance and project outcomes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Elcometer Category

Elcometer 3000 Motorized Clemen Unit

Automation Grade : Semiautomatic

Mounting Type : Benchtop

Features : Motorized movement, precise control, adjustable speed, robust frame

Application : Scratch resistance testing on coated substrates

Measuring Range : Up to 5N (expandable with optional weights)

Equipment Type : Motorized Clemen Unit

Qualicoat Powder Coating Inspection Kit

Automation Grade : Manual

Mounting Type : Handheld, portable

Features : Multitool kit, compliant with Qualicoat, includes crosshatch cutter, gloss meter, film thickness gauge, thermometers, and accessories

Application : Inspection and quality assessment of powder coated surfaces according to Qualicoat standards

Measuring Range : Varies by instrument, e.g., film thickness gauge: 01500 m

Equipment Type : Powder Coating Inspection Kit

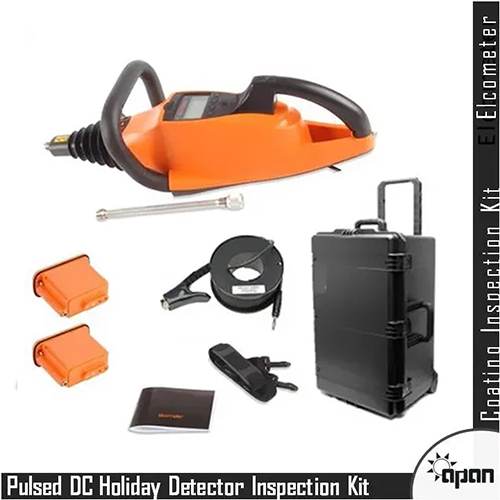

Holiday Detector Inspection Kit

Automation Grade : Manual

Mounting Type : Handheld

Features : Lightweight, adjustable voltage, audible and visual alarm, interchangeable probes

Application : Detecting pinholes, holidays and porosity in coatings

Measuring Range : 030 kV

Equipment Type : Portable Holiday Detector Inspection Kit

Elcometer Blasting Inspection Kit 2

Automation Grade : Manual

Mounting Type : Handheld / Portable

Features : Complete kit for onsite blasting inspection, portable carry case, includes profile gauge, replica tape, dust test kit, salt contamination kit, thermometer, hygrometer

Application : Surface profile, cleanliness, dust, and environmental condition assessment

Measuring Range : Varies by included gauges; profile gauge: 020mm, surface contamination kits as per ISO 8502

Equipment Type : Blasting Inspection Kit

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry