Elcometer Protective Coating Inspection Kit 5

Elcometer Protective Coating Inspection Kit 5 Specification

- Interface Type

- Manual / LCD display

- Test Range

- Multiple ranges; see kit contents

- Application

- Coating inspection (surface profile, dry film thickness, climatic conditions, adhesion)

- Automation Grade

- Manual

- Power Supply

- Typically Battery, some tools manual

- Accuracy

- 2% for DFT gauge, 3% for thermometer/hygrometer

- Display Type

- Digital and analogue (instrument dependent)

- Temperature

- -10C to 50C (digital thermometer included)

- Number of Specimens

- Depends on usage

- Resolution

- 1m DFT, 0.1C thermometer

- Response Time

- Within seconds (digital tools)

- Port Size

- Varies by included instruments

- Specimen Size

- Sample areas from 20mm up

- Measuring Range

- Defined by individual instruments; up to 1500m for DFT gauge

- Features

- Comprehensive kit, portable case, multi-tool inspection

- Mounting Type

- Handheld

- Operating Voltage

- 1.5V batteries (digital gauges)

- Max Height

- Case height: approx. 200mm

- Humidity

- 0100% RH (using digital hyrometer)

- Usage

- Field and laboratory inspection

- Capacity

- Multi-tool kit

- Machine Weight

- 7kg (kit approx.)

- Test Speed

- Manual Operation

- Test Width

- Up to 150mm (dependent on gauge type)

- Test Stroke

- Variable (depends on instrument)

- Control Mode

- Handheld

- Portability

- Lightweight and fully portable kit

- Operating Conditions

- Indoor or outdoor use

- Kit Contents

- Includes digital surface profile gauge, DFT gauge, dewpoint meter, digital thermometer, digital hygrometer, inspection mirror, magnifier, wet film comb

- Calibration

- Supplied with calibration certificates for major instruments

- Case Material

- Durable plastic carry case with foam insert

- Equipment Type

- Protective Coating Inspection Kit

- Data Storage

- Dependent on gauge, some digital

- Service Support

- Global technical service

Elcometer Protective Coating Inspection Kit 5 Trade Information

- Certifications

- AS 1580.108.2, AS 1580.408.4, AS 2331.1.4, AS 3894.3-B, AS 3894.6-A, AS 3894.6-C, AS 3894.6-D, AS 3894.9, AS/NZS 1580.107.3, AS/NZS 1580.108.1, ASTM B 499, ASTM D 1186-B, ASTM D 1400, ASTM D 2200, ASTM D 3359-B, ASTM D 4138-A, ASTM D 4414-A, ASTM D 4417-C, ASTM D 7091, ASTM E 376, ASTM E 797, ASTM G 12, BS 3900-C5-5B, BS 3900-C5-6A, BS 3900-C5-6B, BS 3900-E6, BS 5411-11, BS 5411-3, BS 5599, BS 7079-B4, BS 7079-C5, DIN 50981, DIN 50984, DIN 50986, ECCA T1, ECCA T6, EN 13523-1, EN 13523-6, EN 15317, IMO MSC.215(82), IMO MSC.244(83), ISO 1461, ISO 16276-2, ISO 19840, ISO 2063, ISO 2360, ISO 2409, ISO 2808-12, ISO 2808-1A, ISO 2808-5B, ISO 2808-6A, ISO 2808-6B, ISO 2808-7B, ISO 2808-7C, ISO 2808-7D, ISO 8501-1, ISO 8502-3, ISO 8502-4, ISO 8502-6, ISO 8502-9, ISO 8503-5, JIS K 5600-1-7, NACE RP0287, NF T30-038, NF T30-123, NF T30-124, NF T30-125, SANS 5772, SS 184159, SS 55900, SSPC Guide 15, SSPC PA 2, SSPC VIS 1, SSPC VIS 2, SSPC VIS 3, SSPC VIS 4, SSPC VIS 5, US Navy NSI 009-32, US Navy PPI 63101-000

About Elcometer Protective Coating Inspection Kit 5

As a Authorized dealer we are engaged in providing the broad assortment of Elcometer Digital Inspection Kits.

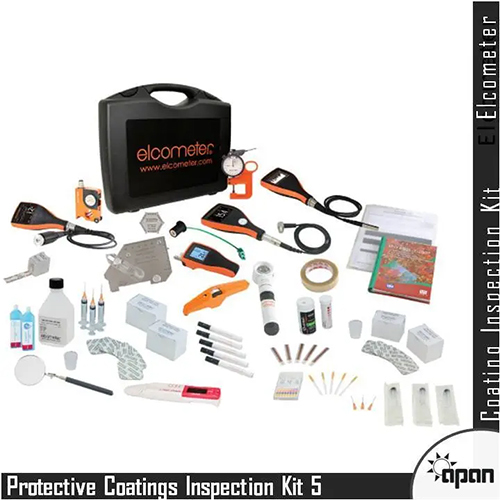

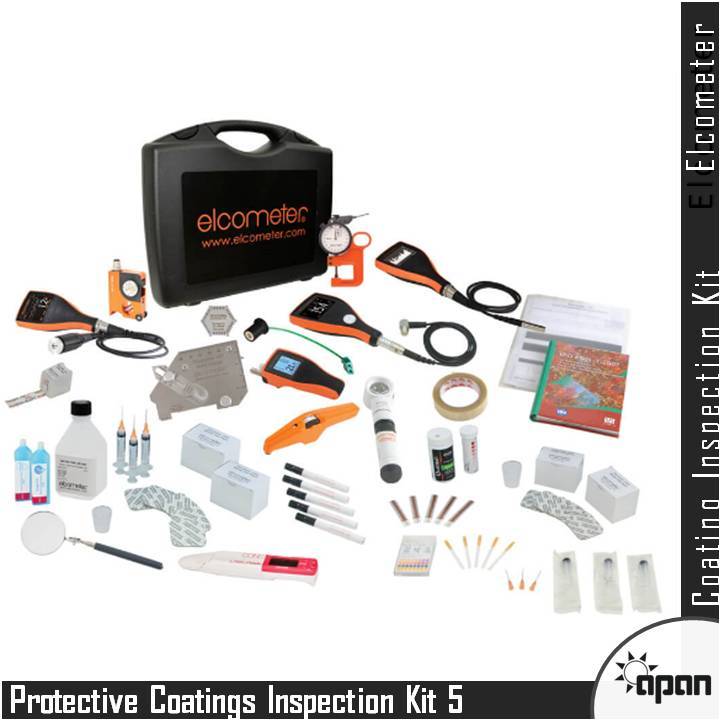

Elcometer Protective Coating Inspection Kit 5

A more comprehensive kit than kits 1-4, the Elcometer Protective Coatings Inspection Kit 5 expands the range of instruments available to the protective coatings inspector.

Measurement parameters include:

- Material thickness

- Surface inspection

- Weld inspection

- Surface cleanliness

- Surface profile

- Climatic conditions

- Coating thickness

- Adhesion

Kit Contents | |

Model | Description |

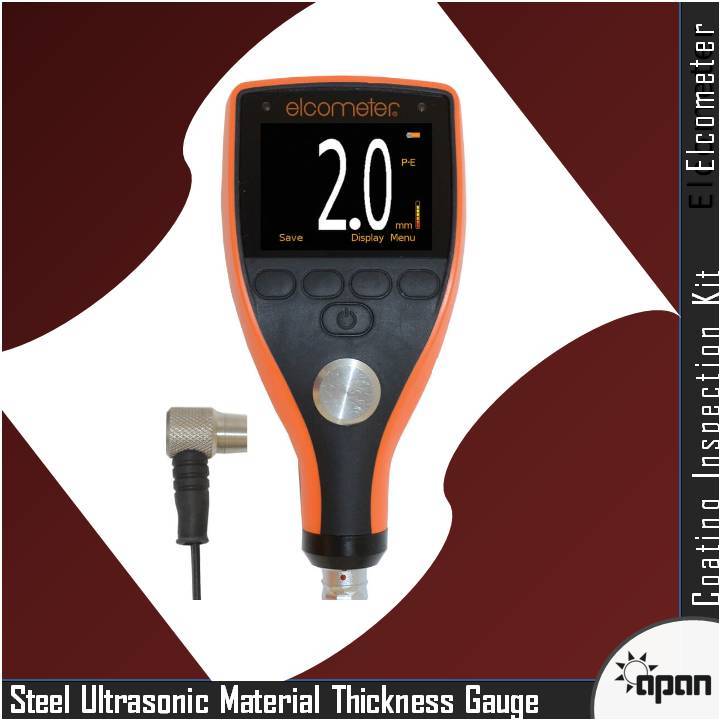

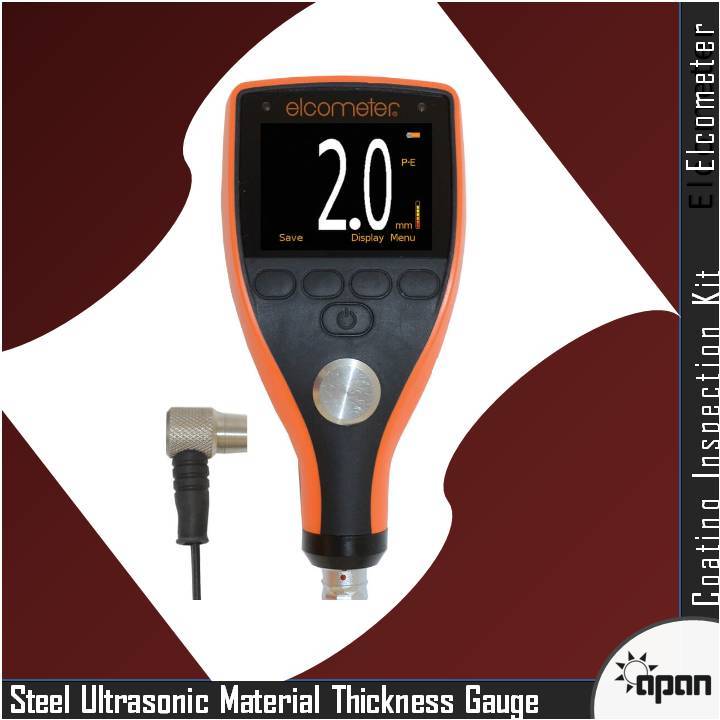

Elcometer 204 | Steel Ultrasonic Material Thickness Gauge |

Elcometer 128 | Pictorial Standards1 |

Elcometer 131/1C | Telescopic Inspection Mirror |

Elcometer 137 | Illuminated Magnifier |

Elcometer 144 | Paint Safe Marker Pens (Pack of 3) |

Elcometer 147 | Weld Gauge |

Elcometer 142 | Dust Tape Test Kit |

Elcometer 138 | Bresle Salt Kit² |

Elcometer 138/2 | Surface Contamination Kit |

Elcometer 122 | Testex Tape, Coarse & Extra Coarse |

Elcometer 124 | Thickness Gauge |

Elcometer 224 | Digital Surface Profile Separate Gauge & Standard Separate Probe, Model T |

Elcometer 319 | Digital Dewpoint Meter, with Magnetic Surface Probe, Top |

Elcometer 112 | Hexagonal Wet Film Comb: 25 - 3000µm (1 - 120mils) |

Elcometer 456 | Separate Digital Coating Thickness Gauge |

Elcometer 121 | Paint Inspection Gauge with Cross Hatch Cutters |

Swedish Rust Standard ISO 8501, SIS055900 supplied in Metric Kit, US Standard SSPC VIS 1-01 and VIS-3 supplied in Imperial Kit

Supplied with Elcometer 135C Bresle Test Patches (x50)

Comprehensive Multi-Tool Inspection

The Elcometer Kit 5 combines all vital tools required for a full assessment of protective coatings. Whether checking surface profile, dry film thickness, or climatic conditions, its array of instruments ensures precise data. The kits versatility makes it indispensable for inspectors who require a wide measurement range with proven accuracy.

Portable and Durable for Field Work

Housed in a lightweight yet sturdy plastic case, this kit is engineered for easy transport and use on-site. The foam insert keeps instruments secure, and the 7kg kit is designed to be fully portable, making it suitable for remote or challenging environments as well as laboratory settings.

Certified Accuracy and Reliable Results

Each major instrument is supplied with a calibration certificate, ensuring dependable accuracy2% for the DFT gauge and 3% for the thermometer and hygrometer. The digital displays and quick-response measurements support fast, reliable data collection, streamlining inspection processes.

FAQs of Elcometer Protective Coating Inspection Kit 5:

Q: How do I use the Elcometer Protective Coating Inspection Kit 5 for surface and coating inspections?

A: Begin by selecting the necessary instrument for your required test, such as the digital surface profile gauge for measuring profile or the DFT gauge for assessing film thickness. Instruments are handheld with manual operation, allowing versatility and quick setup for both field and lab evaluations. Follow provided user manuals for each tool to ensure correct usage.Q: What are the primary benefits of using this kit for protective coating assessment?

A: This kit streamlines the inspection process by combining multiple calibrated instruments in one portable case, ensuring high accuracy, efficiency, and convenience. Certified calibration and robust construction mean reliable data and durability, essential for maintaining quality in demanding environments.Q: When should I calibrate or verify the instruments in the kit?

A: Although each digital gauge and meter is supplied with a calibration certificate, periodic verification is recommendedespecially before major jobs or after prolonged storage. This ensures ongoing measurement accuracy and compliance with industry standards.Q: Where can this inspection kit be used effectively?

A: The Elcometer Kit 5 is suitable for both indoor and outdoor environments. Its operating temperature (-10C to 50C) and humidity range (0100% RH with the digital hygrometer) equip it for diverse climates, including fieldwork on industrial sites or lab-based inspections.Q: What process should I follow for data storage and record-keeping with this kit?

A: Data storage options depend on each digital instrument. Some tools have digital memory to store readings, while others require manual recording. Its recommended to routinely export digital data (if available) and maintain a field log for quality control and traceability.Q: How does the portability of the kit enhance usage during field inspections?

A: Its lightweight, compact design and protective carry case enable inspectors to easily transport all necessary tools, reducing preparation time and equipment loss risk. The kits organization and portability lend themselves to rapid deployment on job sites, optimizing productivity and convenience.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Elcometer Category

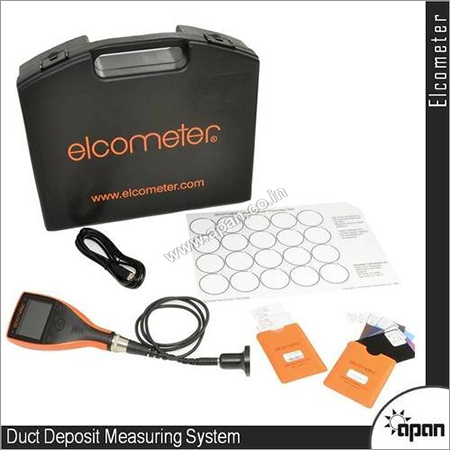

Duct Deposit Measuring System

Automation Grade : Semiautomatic

Equipment Type : Portable Duct Deposit Measuring System

Application : Measurement of dust, grease or particulate deposit in air ducts

Features : Portable, high precision, easy calibration, realtime data output

Usage : HVAC, industrial duct cleanliness verification

Temperature : 10C 60C

Elcometer 102 Needle Pressure Gauge

Automation Grade : Manual

Equipment Type : Needle Pressure Gauge

Application : Measuring air pressure/porosity in concrete and coatings

Features : Portable, durable, easy to use, supplied with connector and hose

Usage : Onsite air pressure checks in construction

Temperature : 10C to 50C

Elcometer Blasting Inspection Kit

Automation Grade : Manual

Equipment Type : Blasting Inspection Kit

Application : Surface Preparation and Blasting Inspection

Features : Comprehensive Kit for Surface Profile, Blast Cleaning & Dust Assessment

Usage : Onsite Inspection and Measurement

Temperature : 10C to 50C Operating Range

Elcometer 119 Pipe Pit Gauge

Automation Grade : Manual

Equipment Type : Pipe Pit Gauge

Application : Measures pit depth and surface irregularities on pipes

Features : Corrosionresistant, durable, compact, portable, easy to read scale

Usage : Pitting, corrosion depth assessment on pipes and tanks

Temperature : 0C to 50C (32F to 122F)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry