Elcometer 3000 Motorized Clemen Unit

Elcometer 3000 Motorized Clemen Unit Specification

- Max Height

- Not specified (N/A)

- Test Range

- 0 5N (graduated) (500g weight supplied standard)

- Automation Grade

- Semi-automatic

- Temperature

- 10C 35C (operating range)

- Humidity

- Ambient / 3585% RH recommended

- Equipment Type

- Motorized Clemen Unit

- Number of Specimens

- 1 at a time

- Features

- Motorized movement, precise control, adjustable speed, robust frame

- Frequency

- 50/60 Hz

- Port Size

- Standard sample holder (20mm width)

- Application

- Scratch resistance testing on coated substrates

- Specimen Size

- 100 x 20mm (typical)

- Display Type

- Analog and digital scale

- Response Time

- Immediate/manual observation

- Mounting Type

- Bench-top

- Operating Voltage

- 110-240V AC

- Measuring Range

- Up to 5N (expandable with optional weights)

- Resolution

- 0.1N

- Interface Type

- Manual (with motorized movement control)

- Accuracy

- 2% of full scale

- Power Supply

- 110240V AC, 50/60Hz

- Gas Pressure

- Ambient/not applicable

- Usage

- Laboratory scratch resistance testing

- Capacity

- Single sample

- Machine Weight

- 23kg (50.7lb)

- Test Speed

- 0 - 40 mm/min (adjustable)

- Test Width

- 20mm

- Test Stroke

- 70mm

- Control Mode

- Motorized (automated linear motion)

- Adjustment

- Variable speed and load

- Construction

- Powder-coated steel body, corrosion resistant

- Safety

- Emergency stop switch, overload protection

- Stylus Width

- 1mm (standard, interchangeable tips available)

- Included Accessories

- 500g weight, stylus, sample holder, instruction manual

- Standards Compliance

- ASTM D5178, ISO 1518, BS 3900

- Track Length

- 70mm

Elcometer 3000 Motorized Clemen Unit Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

About Elcometer 3000 Motorized Clemen Unit

Precise Scratch Resistance Testing

Designed for laboratory environments, the Elcometer 3000 delivers controlled, repeatable linear scratch tests on coated substrates. Its adjustable load and speed settings allow for custom test parameters, while compliance with international standards ensures consistent results across diverse industries.

Robust and Versatile Construction

Built with a powder-coated steel body, the Elcometer 3000 resists corrosion and maintains durability in demanding labs. The unit accommodates interchangeable stylus tips and single specimen testing, making it adaptable for different coating materials and test requirements.

Advanced Safety and Control Features

Equipped with an emergency stop switch and overload protection, the Elcometer 3000 prioritizes user safety during operation. Motorized automation enables precise linear motion, while analog and digital displays offer immediate and accurate measurements for reliable data collection.

FAQs of Elcometer 3000 Motorized Clemen Unit:

Q: How does the Elcometer 3000 perform scratch resistance testing?

A: The unit uses a motorized linear motion to move an interchangeable stylus across a coated sample, applying a variable load (up to 5N). The operator can adjust the speed and observe immediate results via both analog and digital displays.Q: What substrates can be tested with this device?

A: The Elcometer 3000 is designed for coated substrates that fit the supplied sample holder, typically measuring 100 x 20mm. Its suitable for paints, varnishes, and other protective coatings.Q: When should I use the emergency stop switch?

A: Use the emergency stop switch immediately if you encounter operational hazards, malfunction, or risk of specimen damage during testing. This feature halts all movement to ensure user and sample safety.Q: Where is the Elcometer 3000 typically installed or used?

A: It is intended for laboratory bench-top installation, making it ideal for quality control, research, and material testing facilities where standard-compliant scratch resistance analysis is required.Q: What is the process for adjusting speed and load?

A: Operators manually set the desired speed (between 0-40 mm/min) and load (up to 5N). The unit features both analog and digital controls for precise adjustment based on test requirements and standards.Q: What benefits does motorized automation provide?

A: Motorized automation ensures consistent, repeatable motion during tests, reducing human error. It enables fine control of test parameters, improving measurement accuracy and reliability.Q: Can stylus tips be replaced or changed for different tests?

A: Yes, the Elcometer 3000 features interchangeable stylus tips. This allows users to select the appropriate tip width or shape for specific test standards or substrate types.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Elcometer Category

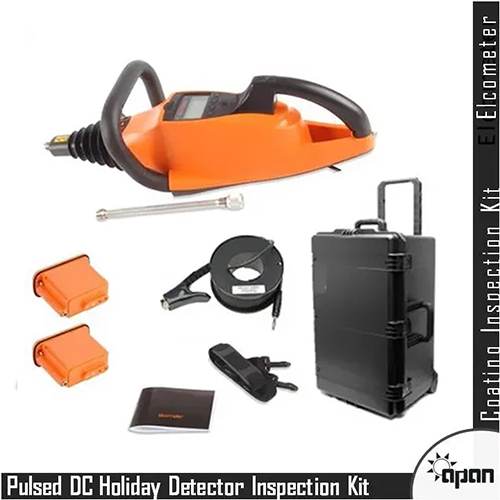

Holiday Detector Inspection Kit

Automation Grade : Manual

Features : Lightweight, adjustable voltage, audible and visual alarm, interchangeable probes

Application : Detecting pinholes, holidays and porosity in coatings

Usage : Field and laboratory coating inspection

Machine Weight : 2.8 kg

Measuring Range : 030 kV

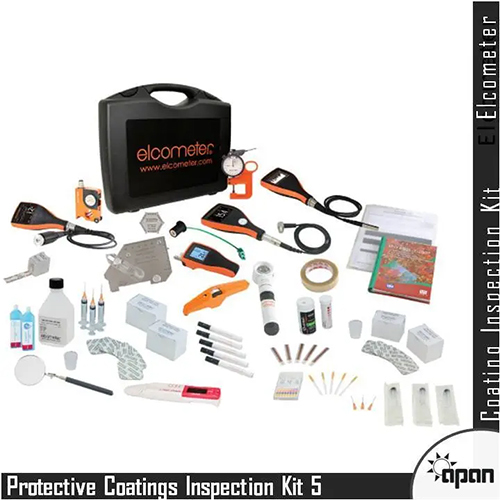

Elcometer Protective Coating Inspection Kit 5

Automation Grade : Manual

Features : Comprehensive kit, portable case, multitool inspection

Application : Coating inspection (surface profile, dry film thickness, climatic conditions, adhesion)

Usage : Field and laboratory inspection

Machine Weight : 7kg (kit approx.)

Measuring Range : Defined by individual instruments; up to 1500m for DFT gauge

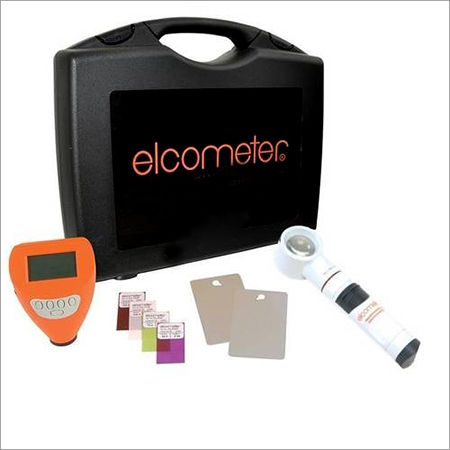

Elcometer Blasting Inspection Kit 2

Automation Grade : Manual

Features : Complete kit for onsite blasting inspection, portable carry case, includes profile gauge, replica tape, dust test kit, salt contamination kit, thermometer, hygrometer

Application : Surface profile, cleanliness, dust, and environmental condition assessment

Usage : Blasting and painting surface preparation inspection

Machine Weight : 6 kg (Kit complete with carry case)

Measuring Range : Varies by included gauges; profile gauge: 020mm, surface contamination kits as per ISO 8502

Elcometer Blasting Inspection Kit

Automation Grade : Manual

Features : Comprehensive Kit for Surface Profile, Blast Cleaning & Dust Assessment

Application : Surface Preparation and Blasting Inspection

Usage : Onsite Inspection and Measurement

Machine Weight : 3.2 kg (Including Carry Case)

Measuring Range : 0 to 1000 m (Depending on Instrument Included)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry